CNTs in Solid-State Batteries: Unlocking the Future of Safer and High-Energy Storage

The global demand for safer, higher-performance batteries is accelerating with the growth of electric vehicles (EVs), renewable energy storage, and consumer electronics. While lithium-ion batteries (LIBs) have dominated for decades, they face limitations: safety concerns from flammable liquid electrolytes, limited energy density, and gradual performance degradation.

This has led researchers and industry leaders to invest heavily in solid-state batteries (SSBs)—a next-generation technology that replaces liquid electrolytes with solid materials. Solid-state batteries promise higher safety, longer lifespan, and greater energy density.

Yet, challenges such as poor ionic conductivity and electrode–electrolyte interface issues have slowed commercialization. To overcome these obstacles, scientists are turning to advanced nanomaterials. Among them, carbon nanotubes (CNTs) stand out as a transformative solution, offering superior conductivity, flexibility, and structural reinforcement.

This article explores the role of CNTs in solid-state batteries, their benefits, applications, and market outlook.

Solid-State Batteries: A Brief Overview

Solid-state batteries use solid electrolytes (ceramic, polymer, or glass-based) instead of liquid electrolytes. Key advantages include:

-

Improved Safety – solid electrolytes eliminate the risk of leakage and thermal runaway.

-

Higher Energy Density – allows for lithium-metal anodes, boosting capacity.

-

Longer Lifespan – less degradation compared to liquid electrolyte systems.

-

Compact and Lightweight – enabling thinner and more efficient battery designs.

However, challenges remain:

-

Low Ionic Conductivity at room temperature.

-

Poor Interface Contact between electrodes and solid electrolytes.

-

Mechanical Stress during charging/discharging cycles.

This is where CNTs can make a significant impact.

Why CNTs? The Science Behind Their Role

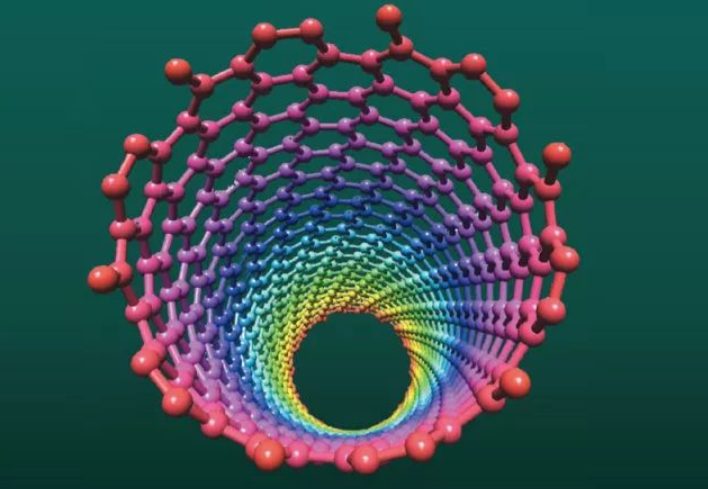

Carbon nanotubes are cylindrical nanostructures composed of rolled-up graphene sheets. They can be single-walled (SWCNTs) or multi-walled (MWCNTs). Their unique properties make them ideal candidates for improving solid-state battery performance:

-

Exceptional Electrical Conductivity – creating efficient electron pathways.

-

High Mechanical Strength – reinforcing electrode structures and preventing cracking.

-

Large Surface Area – enhancing electrode–electrolyte contact.

-

Flexibility – accommodating volume changes during cycling.

-

Lightweight – contributing to higher energy density without significant weight increase.

By integrating CNTs into different parts of the solid-state battery, researchers have observed significant improvements in performance, stability, and efficiency.

How CNTs Enhance Solid-State Batteries

1. Improved Electronic Conductivity

Solid electrolytes often have low electronic conductivity. CNTs create a conductive network within the cathode and anode, ensuring faster electron transfer and reduced internal resistance.

2. Enhanced Interface Contact

CNTs act as a buffer layer between electrodes and solid electrolytes, reducing interfacial resistance and improving ion transport. This helps solve one of the biggest hurdles in SSB technology.

3. Mechanical Reinforcement

During charging/discharging, electrodes expand and contract. CNTs’ high tensile strength provides structural stability, preventing cracks and maintaining long-term performance.

4. Lithium Dendrite Suppression

Lithium-metal anodes, though energy-dense, suffer from dendrite formation. CNTs help distribute lithium uniformly, reducing dendrite growth and improving safety.

5. Faster Ion Transport

CNTs’ large surface area and porous structure improve the percolation of ions, enhancing overall ionic conductivity in composite electrolytes.

Applications of CNT-Enhanced Solid-State Batteries

Electric Vehicles (EVs)

SSBs with CNT integration promise higher driving range, faster charging, and safer operation, making them ideal for next-generation EVs.

Consumer Electronics

Lightweight, thin, and flexible CNT-based SSBs can power foldable smartphones, laptops, and wearable devices with longer battery life.

Renewable Energy Storage

Grid-level storage requires stable, long-lasting, and safe batteries. CNT-enhanced SSBs can provide reliable solutions for storing solar and wind energy.

Aerospace and Defense

CNT-reinforced SSBs are lightweight, safe, and capable of operating in extreme conditions—critical for satellites, drones, and military applications.

CNTs vs. Other Nanomaterials in Solid-State Batteries

-

Graphene: Offers high conductivity but lacks the 3D structural advantages of CNT networks.

-

Silicon Nanoparticles: High capacity but suffer from severe volume expansion.

-

Metal Nanoparticles: Good conductivity but add significant weight.

CNTs provide the best balance between conductivity, mechanical strength, lightweight design, and scalability.

Market Trends and Commercial Potential

The solid-state battery market is projected to reach USD 40–50 billion by 2035, with strong growth driven by EV adoption. CNT-enhanced SSBs are gaining traction due to their ability to address key performance bottlenecks.

Key drivers include:

-

Increasing EV range and safety requirements.

-

Growing demand for lightweight and flexible consumer electronics.

-

Large-scale R&D investments by Toyota, Samsung, QuantumScape, and CATL.

-

Expansion of nanomaterials production facilities worldwide.

Startups and established companies alike are exploring CNT-based additives to make solid-state batteries commercially viable within the next decade.

Challenges and Considerations

-

Production Cost: High-quality CNTs remain relatively expensive.

-

Uniform Dispersion: Preventing CNT agglomeration in electrodes and electrolytes requires advanced processing techniques.

-

Standardization: Lack of industry-wide benchmarks for CNT-enhanced SSBs.

-

Scalability: Transitioning from lab-scale prototypes to gigafactory production is still a major hurdle.

Despite these challenges, ongoing advancements in CNT synthesis and processing are making large-scale application more feasible.

Future Outlook

The integration of CNTs in solid-state batteries will likely accelerate in the next 5–10 years. Future trends may include:

-

CNT-Graphene Hybrids for optimized conductivity and mechanical strength.

-

Printable CNT Inks for scalable, roll-to-roll battery manufacturing.

-

Dendrite-Free Lithium Metal Anodes enabled by CNT scaffolds.

-

Commercial EV Adoption as CNT-enhanced SSBs meet safety and cost requirements.

As manufacturing techniques mature and costs decrease, CNTs will become a mainstream additive in solid-state battery production, revolutionizing energy storage technologies.

Solid-state batteries are widely seen as the next frontier in energy storage, but their commercial success depends on overcoming conductivity and stability challenges. Carbon nanotubes offer an elegant solution—providing superior conductivity, structural reinforcement, and safety enhancements.

From EVs to consumer electronics and renewable energy, CNT-enhanced solid-state batteries have the potential to transform industries and power the transition to a sustainable energy future.

For researchers, manufacturers, and investors, embracing CNT technology today means gaining a competitive edge in tomorrow’s high-performance battery market.