CNTs in Space-Grade Composite Materials: Building the Future of Aerospace Structures

Space exploration demands materials that are ultra-lightweight, mechanically strong, thermally stable, and radiation-resistant. From spacecraft fuselages to satellite components, every gram matters: reducing mass directly lowers launch costs while improving payload capacity.

Traditional aerospace composites, typically carbon fiber-reinforced polymers (CFRPs), have served the industry well. However, even these advanced materials face limitations in terms of fatigue resistance, multifunctionality, and extreme environmental durability.

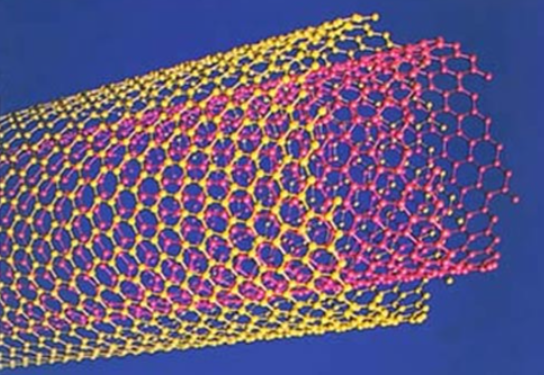

Enter Carbon Nanotubes (CNTs). With their unmatched strength-to-weight ratio, electrical conductivity, and thermal stability, CNTs are poised to become the foundation of next-generation space-grade composite materials.

1. Why CNTs Are Perfect for Space-Grade Composites

CNTs bring a unique set of properties to aerospace applications:

-

Exceptional Mechanical Strength

-

Tensile strength up to 100x stronger than steel while being lighter.

-

-

High Electrical Conductivity

-

Useful for EMI shielding and lightning protection in satellites and spacecraft.

-

-

Thermal Conductivity

-

CNT composites help dissipate heat from electronic systems in vacuum environments.

-

-

Radiation Tolerance

-

More resilient to cosmic radiation compared to traditional composites.

-

-

Multifunctionality

-

CNTs can combine structural, electrical, and thermal roles in a single material.

-

2. Applications of CNTs in Space-Grade Composites

a. Spacecraft Structures

-

CNT-reinforced composites used in fuselages, panels, and satellite housings reduce weight while maintaining durability.

-

High stiffness prevents deformation under launch stress.

b. Satellite Components

-

CNT composites improve thermal management and shielding in satellites.

-

Enable lighter structural supports for solar panels and antenna arrays.

c. Rocket and Launch Vehicle Materials

-

CNTs can reinforce fuel tanks, nozzles, and interstage structures, increasing reliability under extreme pressure and temperature.

d. Space Suits and Habitats

-

CNT-based fabrics offer micrometeoroid protection, radiation shielding, and flexibility for astronauts.

e. Electronics Integration

-

CNT composites enable embedded wiring and EMI shielding, reducing the need for additional cabling.

3. Industrial Progress and Case Studies

-

NASA

-

Actively researching CNT composites for spacecraft structures and radiation shielding.

-

-

ESA (European Space Agency)

-

Testing CNT-based thermal management systems for satellites.

-

-

Lockheed Martin & Boeing

-

Exploring CNT-reinforced polymers for lightweight satellite buses and launch systems.

-

-

Toray Industries (Japan)

-

Developing CNT-enhanced carbon fibers for aerospace-grade composites.

-

These case studies highlight the growing adoption of CNT composites in aerospace R&D, with clear potential for commercialization.

4. Benefits Over Traditional Aerospace Composites

-

CNTs vs. Carbon Fibers

-

Carbon fibers provide high stiffness but lack conductivity; CNTs add electrical and thermal functionalities.

-

-

CNTs vs. Kevlar/Aramid Fibers

-

CNT composites are lighter and stronger while also offering radiation resistance.

-

-

CNTs vs. Metals (Aluminum, Titanium)

-

CNT composites are significantly lighter while matching or exceeding strength.

-

5. Market Opportunities for Exporters and Integrators

For exporters and technology providers, CNT space composites create new avenues:

-

Satellite Manufacturers

-

Supplying CNT composite panels, housings, and thermal shields.

-

-

Launch Service Providers

-

Lightweight CNT fuel tanks and structural supports reduce launch costs.

-

-

Space Robotics and Instruments

-

CNT composites enable durable, lightweight robotic arms and instruments.

-

-

Protective Fabrics

-

Exporting CNT-infused textiles for astronaut suits and habitat shielding.

-

Given the boom in commercial space activities (SpaceX, Blue Origin, satellite mega-constellations), CNT composites are entering a high-growth market where lightweight performance is critical.

6. Challenges and Future Outlook

-

Scalability of Production

-

Large-scale, defect-free CNT composite manufacturing remains challenging.

-

-

Uniform Dispersion

-

Ensuring even distribution of CNTs in polymer matrices is technically complex.

-

-

High Costs

-

Space-grade certification and CNT synthesis costs remain high, though decreasing.

-

-

Standardization

-

Industry-wide testing and qualification standards are still evolving.

-

Despite challenges, the trajectory is clear: CNT composites will move from experimental prototypes to core materials in spacecraft within the next decade.

Carbon Nanotubes are redefining space-grade composite materials, offering unmatched strength, conductivity, and multifunctionality. From lighter spacecraft structures to radiation-resistant fabrics, CNTs provide solutions where traditional composites fall short.

For exporters and integrators, this sector represents a high-value niche market — supplying advanced CNT materials and composite parts to the rapidly growing global space economy.

The future of space exploration will not only depend on rockets and satellites but also on the materials that make them possible — and CNT composites are set to lead that journey.