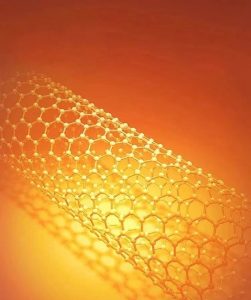

CNTs in Transparent Heaters and Wearable Electronics

How Carbon Nanotubes Enable Flexible, Transparent, and Durable Heating Solutions

Transparent heaters and wearable electronics are rapidly transforming industries such as consumer electronics, healthcare, automotive, and smart textiles. Traditional heating elements—metal wires and ITO films—struggle to meet modern requirements for flexibility, durability, lightweight design, and mechanical stability.

Carbon Nanotubes (CNTs), with their outstanding electrical conductivity, optical transparency, and mechanical flexibility, have emerged as a highly promising material for transparent heaters and wearable heating electronics. This article explores how CNT-based heating systems work, their advantages over conventional materials, manufacturing approaches, and key application scenarios.

1. Why Transparent Heaters and Wearable Electronics Matter

Transparent and wearable heating technologies are essential for:

-

Defogging and de-icing of glass surfaces

-

Thermal comfort in smart clothing

-

Medical therapy and rehabilitation

-

Battery thermal management

-

Human–machine interfaces

To function reliably, heating materials must combine:

-

Electrical conductivity

-

Optical transparency

-

Mechanical flexibility

-

Uniform temperature distribution

-

Long-term stability

CNTs meet these requirements better than most traditional materials.

2. Key Properties of CNTs for Heating Applications

2.1 High Electrical Conductivity

CNT networks form continuous conductive pathways even at low loading levels, enabling efficient Joule heating at low voltages.

2.2 Optical Transparency

Thin CNT films can achieve:

-

85–95% visible light transmission

-

Adjustable sheet resistance (10–1000 Ω/sq)

This balance is ideal for transparent heaters.

2.3 Mechanical Flexibility and Fatigue Resistance

Unlike ITO, CNT films:

-

Do not crack under bending

-

Maintain conductivity after >10,000 bending cycles

-

Can be applied on plastic, textile, and elastomer substrates

2.4 Uniform Heating Performance

CNT networks distribute current evenly, reducing:

-

Local hot spots

-

Thermal stress

-

Material degradation

3. How CNT-Based Transparent Heaters Work

CNT heaters operate via resistive (Joule) heating:

-

Electrical current flows through CNT networks

-

Electrical resistance converts energy into heat

-

Temperature is controlled by voltage and resistance

Because CNT films are continuous and interconnected, heat generation is uniform across the surface.

4. Fabrication Methods for CNT Transparent Heaters

4.1 CNT Thin Films

CNTs are deposited as thin conductive films on substrates such as:

-

PET

-

Polyimide (PI)

-

Glass

-

TPU

Deposition methods include:

-

Spray coating

-

Spin coating

-

Vacuum filtration

-

Slot-die coating

4.2 CNT Inks and Coatings

CNT dispersions are formulated into printable inks for:

-

Screen printing

-

Inkjet printing

-

Gravure printing

This enables scalable, roll-to-roll manufacturing.

4.3 CNT-Polymer Composite Films

CNTs embedded in polymers improve:

-

Mechanical robustness

-

Wash durability (for textiles)

-

Environmental resistance

Used extensively in wearable heating fabrics.

5. CNTs in Wearable Electronics

Wearable electronics require materials that are:

-

Lightweight

-

Skin-safe

-

Flexible

-

Durable under motion

CNT-based systems are well-suited for these demands.

5.1 Smart Heating Textiles

CNT-coated fibers and fabrics provide:

-

Low-voltage heating

-

Soft touch

-

Breathability

Applications include:

-

Heated jackets and gloves

-

Medical thermal garments

-

Outdoor sports apparel

5.2 Medical and Healthcare Wearables

CNT heaters are used in:

-

Thermal therapy patches

-

Muscle relaxation devices

-

Blood circulation aids

Advantages:

-

Precise temperature control

-

Conformable to skin

-

Uniform heat distribution

5.3 Flexible Sensors with Integrated Heating

CNT films can combine:

-

Heating function

-

Strain or pressure sensing

Used in:

-

Rehabilitation monitoring

-

Smart bandages

-

Motion-tracking wearables

6. CNT Transparent Heaters vs Traditional Technologies

| Feature | CNT Heaters | ITO Heaters | Metal Wire Heaters |

|---|---|---|---|

| Transparency | High | High | Low |

| Flexibility | Excellent | Poor | Poor |

| Crack resistance | Excellent | Poor | Moderate |

| Weight | Very low | Moderate | High |

| Processing temperature | Low | High | Low |

| Uniform heating | Excellent | Moderate | Poor |

CNT heaters outperform ITO in flexibility and durability, making them ideal for next-generation devices.

7. Key Applications Beyond Wearables

7.1 Automotive and EV Glass

-

Defogging and de-icing

-

Camera and sensor heating

-

HUD and display heating

CNT heaters are thin, transparent, and reliable under vibration.

7.2 Consumer Electronics

Used in:

-

Smart mirrors

-

Touchscreens

-

Camera lenses

CNT heaters prevent condensation without affecting visibility.

7.3 Aerospace and Industrial Uses

-

Optical window heating

-

Sensor protection

-

Lightweight heating elements

8. Challenges and Engineering Considerations

8.1 Dispersion Quality

Poor CNT dispersion leads to:

-

Uneven resistance

-

Hot spots

-

Reduced lifetime

High-quality CNT inks are essential.

8.2 Sheet Resistance vs Transparency Trade-Off

Lower resistance requires higher CNT density, reducing transparency.

Design optimization balances:

-

Operating voltage

-

Target temperature

-

Optical clarity

8.3 Environmental Stability

Protection layers are often required to prevent:

-

Moisture absorption

-

Mechanical abrasion

-

Oxidation

9. Market Trends and Future Outlook

-

Growing demand for wearable heating and smart textiles

-

Rapid adoption in EV and ADAS systems

-

Integration with graphene for hybrid transparent heaters

-

Expansion into healthcare and rehabilitation devices

CNT-based transparent heaters are moving from niche products to commercially scalable solutions.

CNTs are redefining what transparent heaters and wearable electronics can achieve. Their unique combination of conductivity, transparency, flexibility, and durability allows the creation of heating systems that outperform traditional materials such as ITO and metal wires.

As fabrication techniques mature and costs continue to decrease, CNT-based transparent heaters will play a critical role in smart wearables, flexible electronics, automotive glass, and medical devices.