Commercial Opportunities of Carbon Nanotubes in Aerospace, Defense, and Electronics

Introduction: From Battlefield to Orbit—CNTs Are Reshaping Advanced Industries

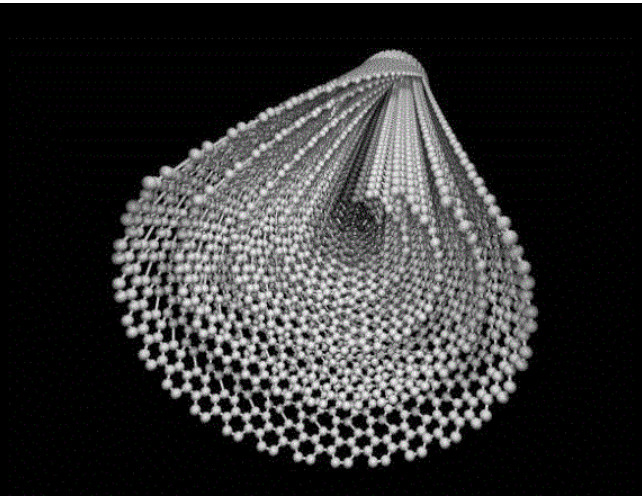

Carbon nanotubes (CNTs) have graduated from the laboratory to the frontline of high-tech innovation. Their ultra-lightweight, high strength-to-weight ratio, and electrical/thermal conductivity make them ideal candidates for sectors demanding superior performance: aerospace, defense, and electronics.

In this article, we explore how CNTs are unlocking next-generation solutions in these sectors—and how manufacturers, investors, and designers can capitalize on their rising commercial relevance.

Part 1: CNT Composites in Aerospace and Defense—Strength Without Weight

1.1 Aerospace Structural Applications

The aerospace industry prioritizes materials that are strong, light, and resistant to extreme environments. CNTs, when embedded into polymer or ceramic matrices, outperform conventional composites.

-

Use Cases:

-

Wing and fuselage reinforcements

-

CNT-epoxy composites for interior components

-

Satellite payload structures

-

✈️ Example: NASA has tested CNT-reinforced carbon fiber composites for CubeSats, showing 30% weight reduction with improved vibration damping.

Advantages:

-

Up to 50% reduction in structural weight

-

Enhanced fatigue resistance and crack propagation control

-

High tolerance to radiation and temperature extremes

1.2 Stealth and EMI Shielding in Defense

CNTs are naturally conductive and can be engineered to form EMI shielding layers:

-

Applications:

-

Stealth coatings for military aircraft (reducing radar cross-section)

-

Electronic compartment shielding in armored vehicles

-

EMI-absorbing wraps for missiles or UAVs

-

🛡️ Data Point: CNT-polymer composites show shielding effectiveness up to 40–60 dB, outperforming carbon fiber or traditional metals per gram.

1.3 Flame Retardant and Blast-Resistant Materials

CNTs can enhance flame retardancy in polymers used in aircraft interiors or protective armor.

-

Hybrid CNT systems (e.g., with nanoclays or boron nitrides) show superior resistance to heat, blast waves, and mechanical failure.

Part 2: CNTs in Advanced Electronics—Miniaturization and Efficiency

2.1 Thermal Interface Materials (TIM)

Electronic systems today are shrinking while their power densities increase. Managing heat is critical.

CNT-based TIMs outperform traditional greases and gels:

-

Vertically aligned CNT (VACNT) arrays act as efficient thermal bridges

-

Measured thermal conductivity: 10–50 W/m·K, depending on alignment and interface

💻 Use Cases:

-

CPUs, GPUs, power modules in EVs

-

LED lighting, 5G base stations

2.2 Interconnects and Conductive Films

As copper interconnects face electromigration limits, CNTs are emerging as strong alternatives:

-

Benefits:

-

Lower resistivity over nanoscales

-

Excellent reliability under thermal cycling

-

Ideal for flexible and stretchable electronics

-

2.3 CNT Field Effect Transistors (CNTFETs)

CNTFETs may one day replace silicon transistors, especially in low-power and flexible electronics:

-

CNTs provide high mobility, ballistic transport, and excellent switching speed

-

Subthreshold swing: <60 mV/decade, exceeding CMOS limits

🧠 R&D: IBM and Stanford have both developed CNTFET-based CPUs with 10000+ CNT transistors, proving viability for future commercial processors.

2.4 Printed Electronics and Transparent Conductors

CNT inks and films are being used in:

-

Touch panels & OLEDs

-

Smart textiles

-

Transparent heating elements (e.g., for aerospace de-icing)

Part 3: ROI Drivers and Commercial Landscape

3.1 High-Margin, Low-Volume Opportunities

Sectors like aerospace and defense offer high margin potential, even with smaller volume demand.

| Application | Estimated Margin | Adoption Readiness |

|---|---|---|

| Aerospace composite panels | 30–40% | High |

| CNTFET integration | 50%+ (on IP) | Medium |

| EMI shielding coatings | 20–25% | High |

3.2 Competitive Players

| Company | Focus Area | Location |

|---|---|---|

| NanoRidge | CNT-enhanced armor | USA |

| OCSiAl | Bulk SWCNTs for composites | Luxembourg |

| LG Chem | CNT conductive pastes | South Korea |

| Zyvex | Aerospace-grade CNT composites | USA |

| Toray | CNT films and hybrid fibers | Japan |

3.3 Government Support & Strategic Funding

-

US DoD funds nanomaterial defense integration under SBIR/STTR programs

-

EU Horizon Europe supports “Green & Smart Aerospace Materials”

-

China’s 14th Five-Year Plan includes nanocarbon for defense & space

Part 4: Challenges and Path to Adoption

4.1 Technical Barriers

-

Scaling production of aligned CNT arrays remains complex

-

Purity: Metallic vs semiconducting CNT ratio needs control for electronics

-

Dispersion issues in polymer matrices for composites

4.2 Regulatory and Safety Considerations

-

Inhalation safety is a concern for CNT powders

-

Need for standardized material handling protocols

4.3 Integration With Legacy Systems

-

Aerospace and defense platforms have long qualification cycles

-

Interoperability with silicon and copper infrastructure requires hybrid approaches

Part 5: Strategic Recommendations for Stakeholders

For Investors:

-

Prioritize IP-rich startups in CNTFET or TIM sectors

-

Look for dual-use potential (military + civilian)

For Material Innovators:

-

Focus on hybrid CNT composites with multifunctionality

-

Collaborate with aerospace primes or defense contractors for field trials

For Electronics Manufacturers:

-

Evaluate cost-per-performance of CNT vs graphene or conventional TIMs

-

Consider CNT films in wearables and foldables to gain early-mover advantage

Conclusion: CNTs Are Lifting Next-Gen Industries Off the Ground

Carbon nanotubes are not a one-trick material. From enhancing aircraft safety, to cooling data centers, to powering ultra-fast processors, they are rewriting the rulebook on performance.

The intersection of high value, clear ROI, and long-term innovation makes CNTs a must-watch technology for the next decade.

💡 Companies who act early—developing supply chains, investing in partnerships, and securing CNT-based patents—stand to lead the next industrial frontier.