Comparing SWCNTs vs MWCNTs – Which Fits Your Application?

1. The Rise of Carbon Nanotubes in Industry

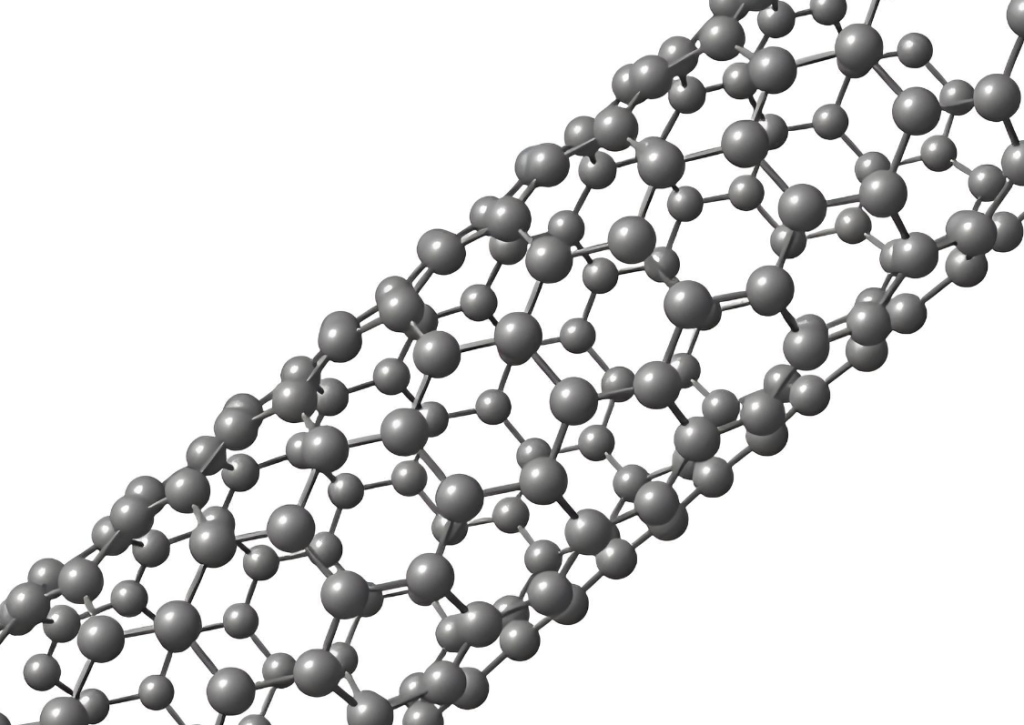

Carbon nanotubes (CNTs) have emerged as one of the most advanced materials with a range of applications in electronics, energy storage, nanocomposites, and more. Within the CNT family, two key types dominate the market: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). Each has unique properties that make it suitable for different applications.

Understanding the differences between SWCNTs and MWCNTs is essential when selecting the right CNT for your project. In this article, we’ll explore the characteristics of each, compare their advantages, and help you determine which type is best suited for your specific application.

2. Key Differences Between SWCNTs and MWCNTs

| Feature | SWCNTs | MWCNTs |

|---|---|---|

| Structure | Single wall, cylindrical graphene sheet | Multiple concentric graphene sheets |

| Diameter | ~1 nm | 2–100 nm |

| Length | Micrometers to millimeters | Micrometers to millimeters |

| Electrical Conductivity | High | Moderate to high |

| Mechanical Strength | Exceptional | High, but lower than SWCNTs |

| Surface Area | Higher | Lower |

| Cost | Higher | Lower |

3. Electrical Conductivity: Which Is Better for Your Application?

One of the primary reasons for selecting CNTs is their exceptional electrical conductivity. The electrical properties of SWCNTs and MWCNTs differ due to their structure:

-

SWCNTs have a higher electrical conductivity due to their single graphene sheet structure. This makes them ideal for applications requiring high performance and conductivity, such as:

-

Transparent Conductive Films (TCFs)

-

Electromagnetic Interference (EMI) Shielding

-

Nanoelectronics

-

-

MWCNTs, while still exhibiting good conductivity, are generally not as efficient as SWCNTs in terms of electrical performance. However, they offer advantages in mechanical strength and cost-effectiveness, making them ideal for:

-

Conductive composites

-

Energy storage systems (batteries, supercapacitors)

-

Electrochemical sensors

-

If high electrical conductivity is your primary concern, SWCNTs are the better choice. But for cost-sensitive applications that still require good conductivity, MWCNTs might be the more practical option.

4. Mechanical Properties: Strength, Flexibility, and Toughness

When it comes to mechanical strength and flexibility, CNTs are superior to most conventional materials. However, there are differences between SWCNTs and MWCNTs:

-

SWCNTs are incredibly strong and exhibit exceptional tensile strength due to their single-layer structure. Their strength-to-weight ratio is one of the highest among known materials, making them ideal for:

-

Lightweight structural composites

-

Aerospace applications

-

High-performance sports equipment

-

-

MWCNTs, with multiple graphene sheets, are also strong but less flexible than SWCNTs. Their multi-wall structure provides higher toughness, which makes them a better fit for:

-

High-impact-resistant composites

-

Electrical cables

-

Mechanical reinforcement in polymers

-

If mechanical strength and flexibility are critical, especially for lightweight applications, SWCNTs are superior. For applications requiring toughness and impact resistance, MWCNTs are more suitable.

5. Surface Area and Functionalization: Tailoring CNTs for Specific Needs

The surface area of CNTs plays a significant role in their ability to interact with other materials, especially in applications like composites, energy storage, and sensors:

-

SWCNTs have a higher surface area due to their single-wall structure. This gives them a better ability to functionalize and bond with different materials, making them ideal for applications that require:

-

High-capacity supercapacitors

-

Nanocomposites for electronics

-

Catalysis applications

-

-

MWCNTs have a lower surface area, but their multiple walls offer more internal space, which can be advantageous in:

-

Energy storage (batteries, supercapacitors) where high-volume applications are needed

-

Longer-lasting mechanical applications like reinforced plastics

-

For applications requiring high surface interaction and reactivity, SWCNTs are preferable, while MWCNTs are more appropriate for applications where bulk properties and cost-efficiency are more important.

6. Cost Considerations: SWCNTs vs MWCNTs

Cost is an important factor when selecting CNTs for large-scale applications:

-

SWCNTs are typically more expensive due to the complexity of their synthesis and higher purity. They are often chosen when performance justifies the higher price.

-

MWCNTs are generally more affordable, making them suitable for mass production or applications with less stringent requirements for electrical conductivity or mechanical strength.

If you’re operating on a budget and the application can tolerate slightly lower performance, MWCNTs are the more cost-effective solution.

7. Applications by Industry

| Industry | SWCNTs | MWCNTs |

|---|---|---|

| Electronics | High-performance circuits, sensors | Conductive composites, energy storage |

| Aerospace | Structural materials, composites | Tough, impact-resistant components |

| Energy Storage | Supercapacitors, high-capacity batteries | Conductive additives for batteries, supercapacitors |

| Composites | Lightweight, high-strength materials | Tough, mechanically reinforced composites |

| Sensors & Catalysis | High surface area for enhanced reactivity | Lower cost, bulk applications |

8. Which CNT Fits Your Application?

-

Choose SWCNTs if:

-

You need high electrical conductivity

-

Lightweight structural performance is required

-

High surface area and functionalization are essential

-

Cost is not the most critical factor

-

-

Choose MWCNTs if:

-

You need cost-effective solutions

-

Toughness and impact resistance are more important than conductivity

-

Large-scale applications with moderate performance requirements

-

Lower surface area and functionalization needs are acceptable

-

Both SWCNTs and MWCNTs offer unique advantages, and your choice depends on the balance between cost, performance, and application requirements.