Comparison: Graphene Heating vs. Traditional Electric Heating Wire

Heating systems are essential in a wide range of applications, from household heating to industrial processes. As energy efficiency, performance, and sustainability become more critical, materials science has paved the way for more advanced heating solutions. Among the emerging technologies, graphene heating stands out as a revolutionary alternative to traditional electric heating wires.

In this article, we will compare graphene heating with traditional electric heating wires, discussing their performance, efficiency, cost, and applications. By understanding the differences and advantages of these two technologies, you can make a more informed decision when choosing a heating solution for your needs.

1. Understanding Traditional Electric Heating Wires

Traditional electric heating wires have been used for decades in various heating applications, such as space heaters, industrial heating systems, automotive seat heaters, and defrosting applications. These heating elements typically consist of metallic wires made from materials like nichrome or copper, which convert electricity into heat through resistance heating.

1.1 How Traditional Heating Wires Work

Electric heating wires work based on the principle of resistance heating, where an electric current passes through a resistive material (like a metal wire), and the material’s resistance to the flow of electricity generates heat. The heat is then transferred to the surrounding environment or objects via convection, radiation, and conduction.

1.2 Advantages of Traditional Heating Wires

-

Proven technology: Traditional electric heating wires are well-established and widely used in various applications.

-

Simple design: These heating elements are straightforward to manufacture and install.

-

Cost-effective: In terms of initial investment, traditional heating wires tend to be less expensive than newer technologies.

1.3 Limitations of Traditional Heating Wires

-

Energy inefficiency: Electric heating wires can be inefficient due to heat loss in the form of radiation and convection. They often require insulation to minimize heat loss, which adds to the overall system complexity.

-

Slow response time: Heating wires can take time to reach the desired temperature, and they often have a delayed response when changes are needed.

-

Limited flexibility: The design of traditional heating wires is constrained by the materials used, which can make them unsuitable for certain applications, such as in flexible or lightweight heating systems.

2. Graphene Heating: A Revolutionary Approach

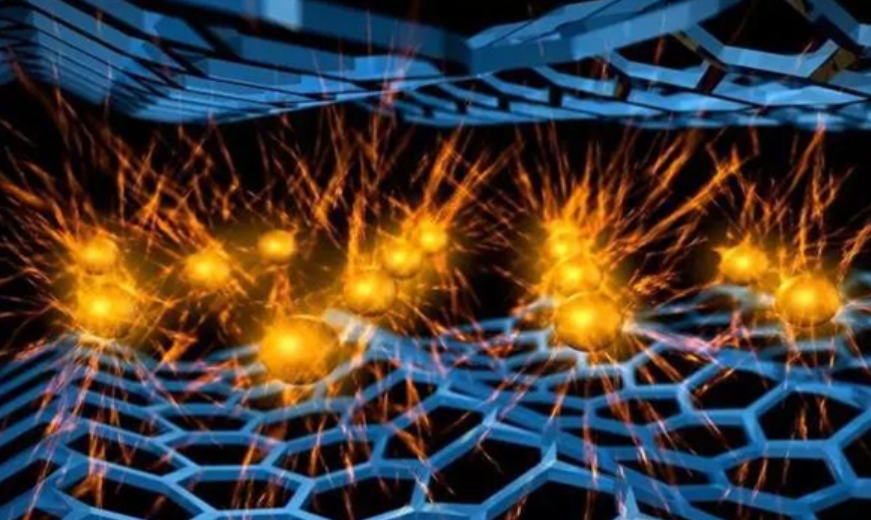

Graphene heating refers to the use of graphene-based materials to generate heat through electrical resistance or direct current. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, has exceptional electrical, thermal, and mechanical properties. These properties make it an attractive alternative to traditional heating methods.

2.1 How Graphene Heating Works

Graphene heating works on a similar principle to traditional electric heating wires, but with the significant advantage of graphene’s high thermal conductivity and electrical properties. When an electric current is passed through a graphene material, it generates heat more efficiently and uniformly compared to traditional materials.

Graphene’s high surface area allows for rapid heat distribution, while its flexibility and thinness enable it to be used in innovative heating solutions that would be challenging with traditional heating wires.

2.2 Advantages of Graphene Heating

-

Faster response time: Graphene heating elements heat up much quicker than traditional electric wires, as graphene can conduct heat and electricity more efficiently.

-

Uniform heat distribution: Graphene’s exceptional conductivity ensures that the heat is distributed evenly across the heating surface, avoiding hot spots and promoting a more consistent heating experience.

-

Thin and flexible: Graphene heating films can be made incredibly thin, lightweight, and flexible, making them ideal for applications where traditional heating wires might be too bulky or rigid.

-

Energy-efficient: Graphene’s high thermal conductivity reduces heat loss, making graphene-based heaters more energy-efficient than traditional systems. This can lead to lower operating costs and improved performance.

-

Durability and flexibility: Graphene’s strength and flexibility make it more durable than traditional heating wires, especially in high-stress applications or in environments where heating elements may undergo mechanical strain.

3. Key Differences: Graphene Heating vs. Traditional Electric Heating Wires

3.1 Heating Speed and Efficiency

-

Graphene Heating: Due to its high electrical and thermal conductivity, graphene-based heating elements heat up faster and more efficiently. This means that they can provide faster temperature responses and improved heat distribution, reducing energy consumption.

-

Traditional Electric Heating Wires: Traditional heating wires, while effective, often have a slower response time. They may require more power to generate the same amount of heat, resulting in lower efficiency and more heat loss.

3.2 Flexibility and Form Factor

-

Graphene Heating: Graphene is a flexible material, allowing it to be integrated into thin films or other flexible substrates. This opens up possibilities for innovative applications, such as heated fabrics, bendable heating elements, and lightweight heating solutions.

-

Traditional Electric Heating Wires: Traditional heating wires are often rigid and bulky, making them difficult to integrate into flexible or compact designs. They also tend to be thicker, which limits their use in certain applications, such as wearables or portable heaters.

3.3 Durability and Longevity

-

Graphene Heating: Graphene is an extremely durable material with high thermal and mechanical stability. This makes graphene heating elements resistant to wear, thermal cycling, and mechanical stress. They are expected to have a longer lifespan than traditional heating wires, even under challenging operating conditions.

-

Traditional Electric Heating Wires: While traditional heating wires are relatively durable, they can suffer from degradation over time due to repeated thermal cycling, mechanical strain, and potential corrosion. This can lead to reduced efficiency and eventual failure.

3.4 Cost

-

Graphene Heating: While graphene heating elements offer superior performance and durability, the initial cost of graphene-based systems can be higher than traditional heating wires due to the cost of graphene production and processing. However, as the technology matures and production methods improve, prices are expected to decrease.

-

Traditional Electric Heating Wires: Traditional heating wires are relatively inexpensive to manufacture and widely available, making them a more affordable option for many applications in the short term. However, their lower efficiency may lead to higher operating costs over time.

3.5 Safety and Environmental Impact

-

Graphene Heating: Graphene heating elements generate less electromagnetic radiation and heat loss compared to traditional wires. Additionally, graphene is a non-toxic and environmentally friendly material, which makes it a more sustainable option in the long run.

-

Traditional Electric Heating Wires: Traditional heating wires can generate significant electromagnetic fields and heat loss, leading to inefficiency and potential safety concerns in some cases. Additionally, the materials used in conventional wires (such as nichrome or copper) are not as environmentally friendly as graphene.

4. Applications of Graphene Heating vs. Traditional Electric Heating Wires

4.1 Graphene Heating Applications

-

Wearables and Smart Clothing: Graphene’s flexibility and thinness make it ideal for use in heated garments such as jackets, gloves, and blankets. These lightweight, flexible heating solutions are far superior to traditional wires, which can be bulky and stiff.

-

Electric Vehicles (EVs): Graphene heating elements can be used for battery thermal management, seat heating, and defrosting systems in EVs. Their superior efficiency and quick response are particularly advantageous in these applications.

-

Building and Floor Heating: Graphene-based floor heating systems can be installed directly into flooring materials or integrated into wall panels, providing even, efficient heating with lower energy consumption.

4.2 Traditional Heating Wires Applications

-

Space Heaters: Traditional heating wires are still widely used in conventional space heaters, offering a simple and effective solution for warming up spaces.

-

Industrial and Commercial Heating: In applications where size and weight are less critical, traditional electric heating wires are commonly used in industrial heating systems, including oven heating elements and air conditioning defrosting.

Both graphene heating and traditional electric heating wires have their respective advantages and are suitable for different applications. However, graphene heating technology offers significant benefits in terms of efficiency, response time, flexibility, and durability, making it an attractive alternative to traditional heating solutions, especially in high-performance, portable, and innovative heating systems.

As graphene production technologies continue to improve and become more cost-effective, we can expect to see wider adoption of graphene heating elements across various industries, offering a greener, more efficient, and longer-lasting solution for advanced heating systems.