Comprehensive Analysis of Carbon Materials: Performance Advantages and Industry Demands

Introduction

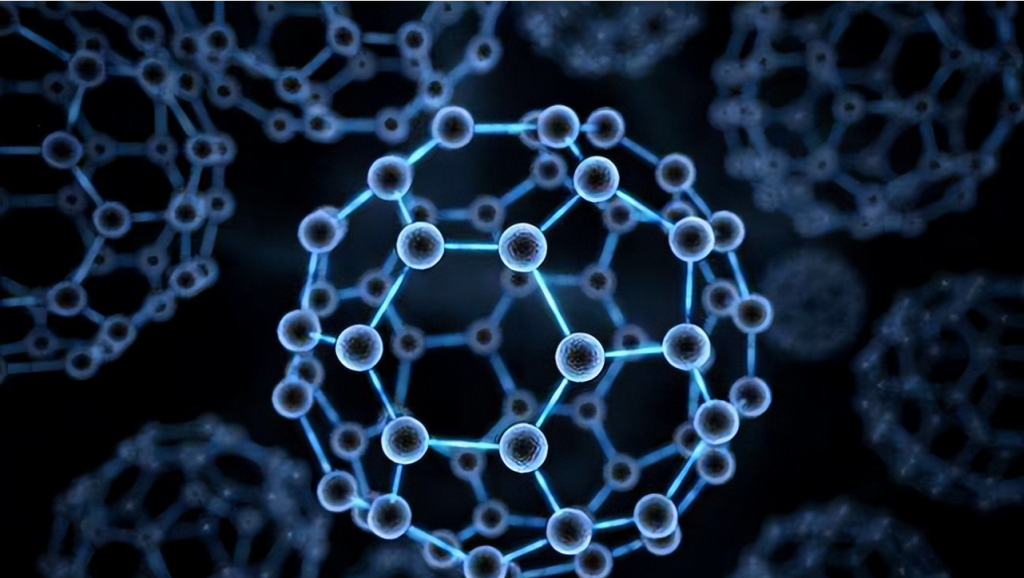

Carbon materials have become indispensable in modern industrial and technological applications, owing to their diverse properties and adaptability. From traditional forms like graphite and activated carbon to advanced nanostructures like graphene and carbon nanotubes (CNTs), each type offers unique advantages that address specific industry needs. This document provides an in-depth analysis of the performance characteristics of various carbon materials and their roles in meeting the demands of key sectors.

Categories of Carbon Materials

1. Graphite

- Properties:

- High thermal and electrical conductivity.

- Excellent chemical stability and lubricating properties.

- Resistant to high temperatures and corrosion.

- Applications:

- Electrodes: Widely used in steelmaking, aluminum production, and energy storage (e.g., lithium-ion batteries).

- Lubricants: Effective in high-temperature environments.

- Refractory Materials: Essential in industries requiring heat resistance.

- Industry Demand:

- High demand from the energy storage and metallurgy industries due to the growth of electric vehicles (EVs) and renewable energy.

2. Graphene

- Properties:

- Exceptional electrical and thermal conductivity.

- High mechanical strength and flexibility.

- Large specific surface area.

- Applications:

- Electronics: Flexible displays, high-speed transistors, and conductive inks.

- Energy: Supercapacitors, fuel cells, and battery enhancement.

- Composite Materials: Strengthening polymers for automotive and aerospace.

- Industry Demand:

- Increasing adoption in advanced electronics, energy storage, and lightweight composite materials.

3. Carbon Nanotubes (CNTs)

- Properties:

- Superior tensile strength and lightweight nature.

- Excellent electrical conductivity and thermal stability.

- High aspect ratio and chemical resistance.

- Applications:

- Structural Reinforcements: Adding strength to polymers and metals.

- Electronics: High-performance transistors and conductive coatings.

- Healthcare: Drug delivery systems and biosensors.

- Industry Demand:

- CNTs are increasingly used in aerospace, construction, and biomedical devices.

4. Activated Carbon

- Properties:

- High porosity and surface area.

- Strong adsorption capacity for gases and liquids.

- Chemical and thermal stability.

- Applications:

- Water and Air Filtration: Removing impurities and toxins.

- Energy Storage: Supercapacitors and gas storage.

- Industrial Processes: Catalyst support and solvent recovery.

- Industry Demand:

- Driven by environmental regulations and demand for cleaner technologies.

5. Carbon Fibers

- Properties:

- High strength-to-weight ratio.

- Corrosion and chemical resistance.

- Thermal and electrical conductivity.

- Applications:

- Aerospace: Lightweight components for aircraft and satellites.

- Automotive: Enhancing fuel efficiency and performance.

- Sports Equipment: High-performance gear like bicycles and tennis rackets.

- Industry Demand:

- Growing use in transportation and renewable energy sectors due to weight reduction and efficiency improvement needs.

Performance Advantages Across Applications

- Energy Sector

- Graphene and CNTs enhance battery and supercapacitor performance, enabling higher energy density and faster charge cycles.

- Activated Carbon is critical for efficient gas storage and environmental applications.

- Electronics and Technology

- Graphene leads innovations in flexible electronics and high-speed processors.

- Carbon Fibers and CNTs are essential for advanced conductive materials and heat management.

- Environmental Solutions

- Activated Carbon plays a vital role in pollution control and carbon capture.

- Graphene-based membranes improve water desalination and purification.

- Aerospace and Automotive

- Lightweight carbon fibers and graphene-reinforced composites enhance fuel efficiency and structural integrity.

- CNTs improve material resilience and reduce wear in high-stress environments.

- Healthcare and Biomedicine

- Graphene and CNTs enable breakthroughs in drug delivery and diagnostics.

- Activated Carbon is used in medical devices for toxin removal and filtration.

Emerging Trends and Development Potential

1. Cost Reduction Through Innovation

- Efforts to scale up graphene and CNT production, such as chemical vapor deposition (CVD), are reducing costs and enabling wider adoption.

2. Sustainability

- Bio-based and renewable carbon materials are gaining traction, supporting global sustainability goals.

- Carbon capture and utilization (CCU) technologies are becoming a focus for reducing greenhouse gas emissions.

3. Integration with Industry 4.0

- Carbon materials are integral to smart technologies, including sensors, IoT devices, and advanced computing systems.

4. Cross-Industry Collaborations

- Partnerships between academia, startups, and industry players are accelerating innovation in carbon materials.

Challenges and Opportunities

Challenges:

- Production Costs: High costs of advanced carbon materials like graphene and CNTs remain a barrier.

- Quality Control: Ensuring consistency in material properties is crucial for industrial adoption.

- Regulatory Hurdles: Standardization and certification are essential for large-scale implementation.

Opportunities:

- Material Diversification: Developing hybrid carbon materials with tailored properties.

- Global Demand: Expanding markets in renewable energy, high-tech industries, and sustainability initiatives.

- Technological Breakthroughs: Advancements in production methods and new applications will drive growth.

Conclusion

Carbon materials, with their diverse forms and properties, are reshaping industries and driving innovation. Their unique advantages, ranging from high strength and conductivity to environmental benefits, position them as essential materials for future technologies. As research and development continue to address current challenges, the potential of carbon materials to meet evolving industry demands and sustainability goals will only grow, making them a cornerstone of modern industrial and technological progress.