Conductive Inks for Printed Electronics – Benefits of Nanocarbon

1. The Rise of Printed Electronics

Printed electronics has emerged as a transformative manufacturing approach for electronic devices, enabling low-cost, large-area, and flexible circuit fabrication. Applications range from RFID antennas and flexible sensors to smart packaging, wearable devices, and human–machine interfaces.

At the core of printed electronics lies conductive ink, which must deliver reliable electrical performance while remaining compatible with high-throughput printing processes. Traditional conductive inks based on silver, copper, or conductive polymers face challenges related to cost, oxidation, mechanical durability, and environmental stability.

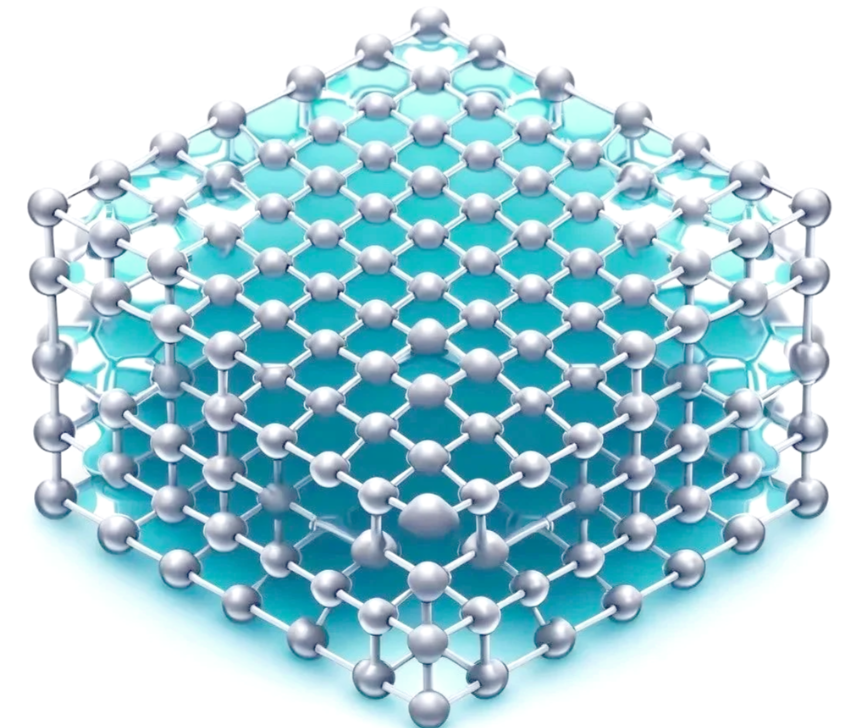

Nanocarbon materials—particularly graphene and carbon nanotubes (CNTs)—are increasingly recognized as enabling materials that address many of these limitations and unlock new design possibilities in printed electronics.

2. Functional Requirements of Conductive Inks

To perform effectively in printed electronics, conductive inks must meet several key requirements:

-

High electrical conductivity at low loading

-

Good dispersion stability and printability

-

Compatibility with various substrates (PET, paper, textiles, elastomers)

-

Mechanical flexibility and fatigue resistance

-

Low-temperature or post-print curing capability

Meeting all these requirements simultaneously is difficult with conventional metal-based inks.

3. Why Nanocarbon Materials Are Ideal for Conductive Inks

Nanocarbon materials offer a combination of properties that are uniquely suited to printed electronics.

3.1 Cost and Supply Chain Advantages

Silver-based inks dominate high-performance applications but suffer from:

-

High and volatile material costs

-

Resource constraints

Graphene and CNTs offer more stable long-term cost structures, particularly for large-area and disposable electronics.

3.2 Mechanical Flexibility and Reliability

Nanocarbon conductive networks maintain conductivity under:

-

Bending

-

Stretching

-

Repeated mechanical cycling

This makes them ideal for flexible and wearable electronics, where metal inks often crack or delaminate.

3.3 Oxidation and Environmental Stability

Unlike copper inks, nanocarbon materials do not oxidize under ambient conditions, eliminating the need for complex protective processing.

3.4 Low-Temperature Processing

Nanocarbon inks can achieve conductivity without high-temperature sintering, enabling printing on:

-

Plastic films

-

Paper

-

Heat-sensitive substrates

4. Types of Nanocarbon Conductive Inks

4.1 Graphene-Based Conductive Inks

Graphene inks provide:

-

Moderate-to-high conductivity

-

Good transparency potential

-

Smooth film formation

They are commonly used in:

-

Flexible interconnects

-

Touch sensors

-

Transparent electrodes

4.2 CNT-Based Conductive Inks

CNT inks form percolating networks at low loadings due to their high aspect ratio, offering:

-

Superior flexibility

-

High fatigue resistance

-

Stable conductivity under strain

CNT inks are often used in:

-

Strain sensors

-

Wearable electronics

-

Stretchable circuits

4.3 Hybrid Nanocarbon Inks

Combining graphene and CNTs allows:

-

Improved conductivity

-

Better film uniformity

-

Tunable rheology for different printing methods

Hybrid inks are increasingly adopted in commercial designs.

5. Printing Technologies and Compatibility

Nanocarbon inks are compatible with multiple printing methods:

-

Screen Printing: Thick films, robust conductivity

-

Inkjet Printing: Fine patterns, low material usage

-

Gravure Printing: High-speed roll-to-roll production

-

Aerosol Jet Printing: High-resolution 3D structures

Rheological tuning is essential to match ink formulation with printing technique.

6. Key Design Considerations

6.1 Dispersion Quality

Uniform dispersion of nanocarbon materials is critical for:

-

Electrical consistency

-

Print resolution

-

Long-term stability

Agglomeration leads to nozzle clogging and uneven conductivity.

6.2 Binder and Solvent Selection

Binders influence:

-

Adhesion to substrates

-

Mechanical flexibility

-

Environmental resistance

Solvent choice affects drying behavior and printing speed.

6.3 Conductivity vs. Transparency

For applications such as transparent electrodes, engineers must balance:

-

Sheet resistance

-

Optical transmittance

Graphene-based inks are often preferred where transparency is required.

7. Application Areas

7.1 Flexible and Wearable Electronics

Nanocarbon inks enable:

-

Skin-mounted sensors

-

Smart textiles

-

Flexible circuits

Their durability under motion is a key advantage.

7.2 RFID and Antennas

Printed antennas benefit from:

-

Stable conductivity

-

Low material cost for large-area patterns

Nanocarbon inks provide a viable alternative to silver in cost-sensitive applications.

7.3 Sensors and Human–Machine Interfaces

CNT-based inks are particularly effective in:

-

Pressure sensors

-

Strain gauges

-

Touch interfaces

Their resistance changes under deformation enable multifunctional sensing.

7.4 Smart Packaging and IoT Devices

Low-cost, disposable electronics require:

-

Scalable printing

-

Environmentally stable materials

Nanocarbon inks support these requirements.

8. Manufacturing and Commercialization Challenges

Challenges include:

-

Achieving metal-like conductivity at low loading

-

Standardization of nanocarbon material quality

-

Integration into existing printing lines

Ongoing advances in material functionalization, hybrid formulations, and process optimization continue to improve commercial readiness.

9. Future Outlook

Nanocarbon conductive inks are expected to play a key role in:

-

Fully printed electronic systems

-

Flexible energy storage integration

-

Sustainable electronics manufacturing

As performance improves and costs decline, nanocarbon inks will increasingly complement or replace metal-based systems in many applications.

Nanocarbon materials offer a compelling pathway for advancing conductive inks in printed electronics. By combining electrical performance, mechanical durability, and processing flexibility, graphene and CNT-based inks address many limitations of traditional conductive materials.

For designers and manufacturers seeking scalable, flexible, and cost-effective electronic solutions, nanocarbon conductive inks represent a powerful enabling technology.