Conductivity Comparison: Carbon Black vs. CNT vs. Hybrid Systems in Lithium Battery Electrodes

Conductive additives are an indispensable component of lithium-ion battery electrodes. While they occupy a relatively small proportion of the total electrode mass (typically 1–5%), their influence on electronic conductivity, rate capability, and cycle life is substantial. The three major categories of conductive additives in commercial use are:

-

Conductive carbon black (CB) – such as Super P, Ketjenblack

-

Carbon nanotubes (CNTs) – including single-walled (SWCNT) and multi-walled (MWCNT)

-

Hybrid systems – combinations of carbon black, CNTs, and sometimes graphene

This article offers a comparative analysis of these three types in the context of lithium battery electrodes, highlighting the advantages, trade-offs, and key use cases for each.

1. Overview of Conductive Additives

a. Carbon Black (CB)

CB is the most commonly used conductive additive in the lithium battery industry due to its low cost, good dispersibility, and moderate conductivity.

-

Common types: Super P, Acetylene Black, Ketjenblack EC-600JD

-

Particle size: 30–100 nm

-

Surface area: 50–1500 m²/g

-

Dosage: typically 2–4 wt%

Advantages:

-

Inexpensive

-

Easy to disperse in NMP or water-based slurries

-

Readily available at scale

Disadvantages:

-

Requires high dosage

-

Forms isolated clusters rather than a continuous network

-

Limits energy density at high loadings

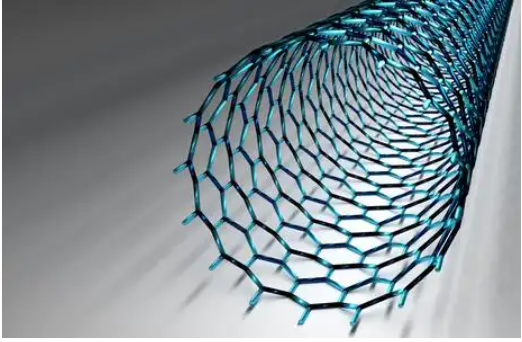

b. Carbon Nanotubes (CNTs)

CNTs offer a one-dimensional nanostructure with superior electrical conductivity and mechanical flexibility. Both SWCNTs and MWCNTs are used in the battery industry.

-

Aspect ratio: >1000

-

Surface area: 200–1000 m²/g

-

Dosage: 0.1–0.5 wt%

Advantages:

-

Forms effective 3D conductive networks

-

Requires lower loading than CB

-

Enhances rate capability and cycle life

-

Maintains conductivity during volume changes (e.g., silicon anodes)

Disadvantages:

-

More expensive

-

Processing requires dispersion aids and optimized mixing

c. Hybrid Conductive Systems

To balance cost, performance, and processability, many manufacturers now use hybrid systems combining CB and CNTs. These systems offer:

-

Lower overall dosage

-

Better conductivity than CB alone

-

Easier processing than pure CNT systems

-

Greater flexibility for performance tuning

Hybrid approaches may also include graphene, vapor-grown carbon fibers (VGCF), or conductive polymers, depending on the application.

2. Electrical Conductivity: Comparative Metrics

| Material | Intrinsic Conductivity (S/m) | Typical Dosage in Battery | Conductivity per wt% (Normalized) |

|---|---|---|---|

| Carbon Black | ~10²–10³ | 2–4 wt% | 1× |

| MWCNT | ~10⁴–10⁵ | 0.2–0.5 wt% | ~8× |

| SWCNT | ~10⁶–10⁷ | 0.05–0.1 wt% | ~20× |

| Hybrid (CB + CNT) | Intermediate | 0.5–1.5 wt% | ~5–10× |

Note: Conductivity per wt% is a relative performance metric comparing the effectiveness of the material in forming a percolative network.

3. Impact on Electrode Performance

a. Energy Density

-

Carbon black requires more space, reducing the proportion of active material.

-

CNTs, especially SWCNTs, deliver required conductivity at lower loadings, allowing more room for active materials → higher energy density.

-

Hybrid systems strike a balance.

b. Power Density and Rate Capability

-

CB forms localized clusters with limited long-range connectivity.

-

CNTs create extended conductive pathways, allowing for faster electron transport.

-

Hybrids enhance power density without significant cost increase.

c. Cycle Life

-

Electrodes with CNTs or hybrids tend to have better mechanical integrity.

-

CNT networks accommodate volume changes, reducing degradation.

-

CB-only electrodes may crack or suffer from increased resistance over time.

4. Processability and Dispersion

Carbon Black:

-

Excellent dispersion in most binder systems

-

Minimal shear or sonication required

CNTs:

-

Require optimized dispersion methods:

-

High-shear mixing

-

Surfactants (e.g., SDBS, XFZ20)

-

Ultrasonic treatment

-

-

Can agglomerate without proper dispersion

Hybrid Systems:

-

Pre-formulated pastes (e.g., CNT/CB in PVDF matrix)

-

Easier to handle and integrate into existing production lines

-

Growing popularity in slurry-type electrode production

5. Cost Comparison

| Material | Typical Market Price (USD/kg) | Application Scenario |

|---|---|---|

| Carbon Black | $3–10 | Standard LIBs |

| MWCNT | $30–80 | High-rate cells |

| SWCNT | $1000–3000 | Premium batteries |

| Hybrid Systems | $20–60 | Mass production EVs |

Cost Implications:

-

CB dominates in low-cost applications.

-

CNTs are preferred in high-performance or fast-charging cells.

-

Hybrids are becoming mainstream due to balanced price/performance.

6. Real-World Use Cases

-

Carbon Black:

-

LFP batteries for e-scooters, power tools

-

Low-cost consumer electronics

-

-

MWCNT:

-

EV battery manufacturers like CATL, BYD, EVE Energy

-

Enhanced rate performance and safety

-

-

SWCNT:

-

Used in solid-state battery R&D, aerospace, and niche high-performance batteries

-

Adopted by global innovators such as LG Chem and Panasonic

-

-

Hybrid Systems:

-

Emerging as the new standard for mid- to high-end EV batteries

-

Many Chinese slurry producers offer ready-to-use hybrid pastes

-

7. Environmental and Regulatory Considerations

-

Carbon Black: Relatively benign; long history of industrial use

-

CNTs:

-

Subject to regulation in some regions (e.g., REACH in Europe)

-

Safe handling and proper containment are critical

-

-

Hybrid Systems: Tailored for compliance while achieving performance targets

Conclusion

The choice of conductive additive in lithium battery electrodes is no longer a simple cost decision. Instead, it’s a performance-engineering trade-off influenced by:

-

Desired energy and power density

-

Electrode formulation and processing constraints

-

End-application (consumer, automotive, aerospace)

-

Regulatory and environmental standards

As a general guideline:

-

Use carbon black for cost-sensitive, lower-performance cells.

-

Choose MWCNTs for enhanced power and cycle life.

-

Opt for SWCNTs in high-end applications where space and performance are at a premium.

-

Leverage hybrid systems to balance cost, conductivity, and processability.

With new slurry technologies and evolving battery designs, the future of conductive systems lies in optimized hybrids that combine the best of each material type. Smart material selection today can mean breakthrough battery performance tomorrow.