Cost Control and Scalable Production of Graphene Coatings

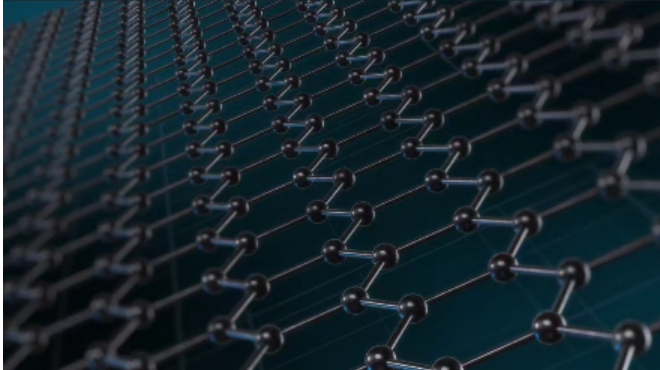

Graphene-based coatings offer exceptional conductivity, corrosion resistance, and durability, but their commercial adoption depends on cost-effectiveness and scalable production. This article explores key strategies for cost control and large-scale manufacturing of graphene coatings.

1. Major Cost Factors in Graphene Coating Production

A. Graphene Raw Material Costs

Graphene’s cost is highly dependent on its type, purity, and production method:

| Graphene Type | Production Method | Cost Range (USD/kg) | Properties & Application |

|---|---|---|---|

| Monolayer Graphene | CVD (Chemical Vapor Deposition) | $500+ | High-performance coatings, electronics |

| Multilayer Graphene | Liquid-phase exfoliation | $50–$200 | Conductive, anti-corrosion coatings |

| Reduced Graphene Oxide (rGO) | Chemical reduction | $10–$50 | Cost-effective, functional coatings |

-

Cost Reduction Strategies:

-

Using multilayer graphene or rGO instead of monolayer graphene.

-

Sourcing graphene from bulk exfoliation or scalable chemical methods.

-

Optimizing synthesis to reduce waste by-products and energy consumption.

-

B. Dispersion & Stabilization Costs

Graphene tends to agglomerate, requiring specialized dispersants and surfactants to ensure uniform distribution.

-

Cost Considerations:

-

Use of cost-effective surfactants instead of expensive polymer stabilizers.

-

Ultrasonic dispersion and high-shear mixing to replace chemical modification.

-

Selection of resins and solvents that naturally interact with graphene.

-

C. Binder and Resin Selection

Binders contribute 30–50% of the total cost of graphene coatings.

| Binder Type | Cost ($/kg) | Application |

|---|---|---|

| Epoxy Resins | $5–$15 | Industrial & marine coatings |

| Polyurethane (PU) | $3–$10 | Wear-resistant & flexible coatings |

| Acrylic Resins | $2–$5 | Waterborne & decorative coatings |

-

Cost Control Strategies:

-

Replacing solvent-based binders with water-based resins.

-

Optimizing graphene-to-binder ratio for performance without excessive cost.

-

2. Scalable Production Techniques for Graphene Coatings

A. Scalable Graphene Synthesis for Coatings

Scaling up graphene production requires high-yield, low-cost methods:

| Method | Scalability | Cost Efficiency | Quality |

|---|---|---|---|

| CVD Growth | Low | High cost | Highest purity |

| Liquid-phase Exfoliation | High | Moderate | Good dispersion |

| Graphite Oxidation & Reduction (rGO) | Very High | Low | Functionalized graphene |

-

For large-scale production, liquid-phase exfoliation and chemical reduction of graphene oxide (rGO) are preferred due to their low cost and high yield.

B. Industrial Dispersion & Coating Formulation

To ensure uniform graphene dispersion at large volumes, scalable methods include:

-

High-Shear Mixing: Cost-effective method for blending graphene into liquid coatings.

-

Ultrasonic Processing: Reduces agglomeration but increases power consumption.

-

Three-Roll Milling: Ensures fine dispersion for high-performance coatings.

-

Optimization Strategy: Selecting the most energy-efficient dispersion method based on application needs.

C. Large-Scale Coating Application Methods

To reduce manufacturing costs, graphene coatings should be compatible with existing industrial coating processes:

| Application Method | Scalability | Graphene Suitability |

|---|---|---|

| Spray Coating | High | Automotive, aerospace |

| Roll-to-Roll Coating | Very High | Electronics, large surfaces |

| Dip Coating | Medium | Protective coatings |

| Spin Coating | Low | Precision applications |

-

Cost Optimization:

-

Integrating graphene into existing coating production lines to avoid new equipment costs.

-

Using automated spray and roll-to-roll processes for high-throughput production.

-

3. Key Cost Control Strategies

| Cost Factor | Optimization Strategy |

|---|---|

| Graphene Sourcing | Use rGO or multilayer graphene for cost-sensitive applications |

| Dispersion Process | Replace expensive dispersants with mechanical methods (e.g., high-shear mixing) |

| Resin/Binder Selection | Optimize graphene loading, use waterborne resins where applicable |

| Manufacturing Process | Scale production with roll-to-roll & spray coating for efficiency |

| Energy & Waste Management | Implement solvent recycling & energy-efficient mixing |

4. Future Trends in Cost Reduction & Scaling

-

AI & Machine Learning for Formulation Optimization: Reducing trial-and-error in graphene coating development.

-

Hybrid Nanomaterial Coatings: Combining graphene with carbon nanotubes (CNTs) or boron nitride to reduce graphene content while maintaining performance.

-

Green Manufacturing: Development of bio-based graphene production and low-energy exfoliation techniques.

5. Conclusion

Scalability and cost control are critical to commercializing graphene-enhanced coatings. By optimizing raw material selection, dispersion techniques, binder systems, and application methods, manufacturers can produce high-performance coatings at competitive prices. As industrial-scale graphene production advances, the cost of graphene coatings will continue to decrease, making them more accessible for automotive, aerospace, marine, and industrial applications.