Custom Formulation Services for Conductive Coatings

1. Why Off-the-Shelf Conductive Coatings Often Fail

Conductive coatings are widely used in applications such as EMI shielding, ESD control, printed electronics, sensors, and functional surfaces. While many standard formulations are available on the market, off-the-shelf conductive coatings rarely meet all application requirements simultaneously.

Real-world applications differ in substrate type, target conductivity, mechanical stress, environmental exposure, and processing conditions. As a result, achieving reliable performance often requires custom formulation rather than generic products.

Custom formulation services bridge the gap between material potential and application-specific performance.

2. What Custom Formulation Means in Conductive Coatings

Custom formulation is not simply adjusting filler content. It is a system-level optimization that considers:

-

Conductive filler selection (CNT, graphene, carbon black, hybrids)

-

Binder and resin compatibility

-

Dispersion stability

-

Rheology and processability

-

Electrical, mechanical, and environmental performance

The goal is to deliver a coating that performs consistently under real operating conditions.

3. Key Parameters in Conductive Coating Design

3.1 Target Conductivity Range

Different applications require different conductivity levels:

-

EMI shielding: low surface resistance

-

ESD control: controlled dissipation range

-

Sensors: tunable resistance response

Over-designing conductivity often increases cost and reduces stability.

3.2 Substrate Compatibility

Conductive coatings must adhere to:

-

Plastics (ABS, PC, PET, TPU)

-

Metals

-

Glass

-

Textiles

Custom formulations ensure strong adhesion without compromising flexibility or durability.

3.3 Mechanical and Environmental Requirements

Coatings may be exposed to:

-

Bending or strain

-

Temperature cycling

-

Humidity or chemical exposure

Custom formulations optimize filler–matrix interaction to maintain performance.

4. Conductive Filler Options and Selection Strategy

4.1 CNT-Based Systems

CNTs enable:

-

Low loading levels

-

Stable conductive networks

-

Excellent strain resistance

They are ideal for flexible and high-reliability coatings.

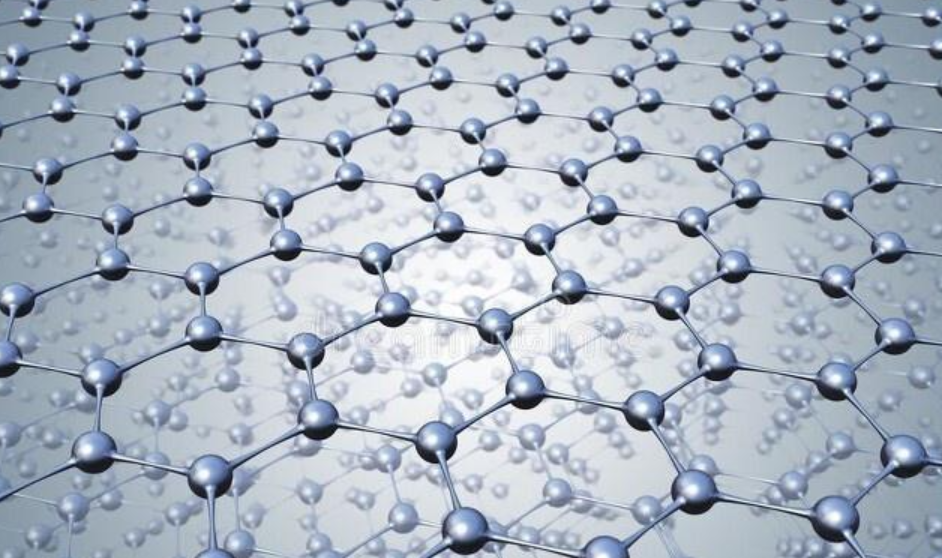

4.2 Graphene-Based Systems

Graphene offers:

-

High in-plane conductivity

-

Thermal management benefits

-

Cost-effective enhancement at moderate loading

Often used in coatings requiring thermal and electrical balance.

4.3 Hybrid Filler Systems

Hybrid systems combine:

-

CNTs for network stability

-

Carbon black or graphene for cost optimization

These systems frequently provide the best cost–performance balance.

5. Processing and Application Methods

Custom formulations are tailored to specific processes, including:

-

Spray coating

-

Screen printing

-

Slot-die and roll-to-roll coating

-

Dip coating

Rheology and drying behavior are tuned to ensure uniform coatings at scale.

6. Development Workflow for Custom Conductive Coatings

A structured development approach ensures efficient formulation:

-

Application requirement analysis

-

Preliminary material selection

-

Laboratory formulation and testing

-

Performance optimization

-

Pilot-scale validation

-

Scale-up and quality control

This process minimizes development risk and accelerates time to market.

7. Performance Validation and Quality Control

Custom formulations undergo validation for:

-

Sheet resistance consistency

-

Adhesion and durability

-

Environmental stability

-

Batch-to-batch reproducibility

Data-driven validation ensures coatings perform reliably in production.

8. Typical Applications

Custom conductive coatings are widely used in:

-

EMI shielding enclosures

-

ESD floors and surfaces

-

Flexible circuits and sensors

-

Functional industrial coatings

Each application benefits from tailored material design.

9. Why Custom Formulation Delivers Better ROI

Compared to generic products, custom formulations offer:

-

Lower total system cost

-

Reduced failure and rework rates

-

Improved performance stability

-

Stronger differentiation for end products

These advantages translate directly into better ROI.

Conductive coatings are complex material systems where small formulation changes can have significant performance impacts. Custom formulation services enable manufacturers to move beyond compromise solutions and achieve reliable, application-optimized performance.

By combining nanocarbon materials, formulation expertise, and application-driven engineering, custom conductive coatings deliver measurable technical and commercial value.