Heating Cable Manufacturers: Why Do They Avoid Focusing on Cable Types?

Heating cable manufacturers rarely emphasize the differences between various types of heating cables. Instead, they highlight two main aspects: the difference between imported and domestic brands, and the electromagnetic radiation standards for heating cables.

Most heating cable companies compete fairly, focusing on product quality, pricing, and after-sales service. This is because heating cable technology and materials are relatively simple, leaving little room for shortcuts.

How is the Electric Heating Film Industry Different?

The electric heating film industry, on the other hand, is much more complex. There are several recognized types of electric heating films: “polymer, ink, carbon fiber, and metal wire (or sheet).” Additionally, there are various other names, such as “silicon crystal, carbon crystal, electric heating floor film, carbon-based, graphene, PTC, eco-friendly,” each with different marketing claims.

Many companies claim their products are “the first,” “the only,” or “the best,” reflecting the chaotic and unregulated state of the electric heating film market. If a company can’t clearly define its own product category, how can consumers trust their claims about product performance?

Lack of Industry Standards

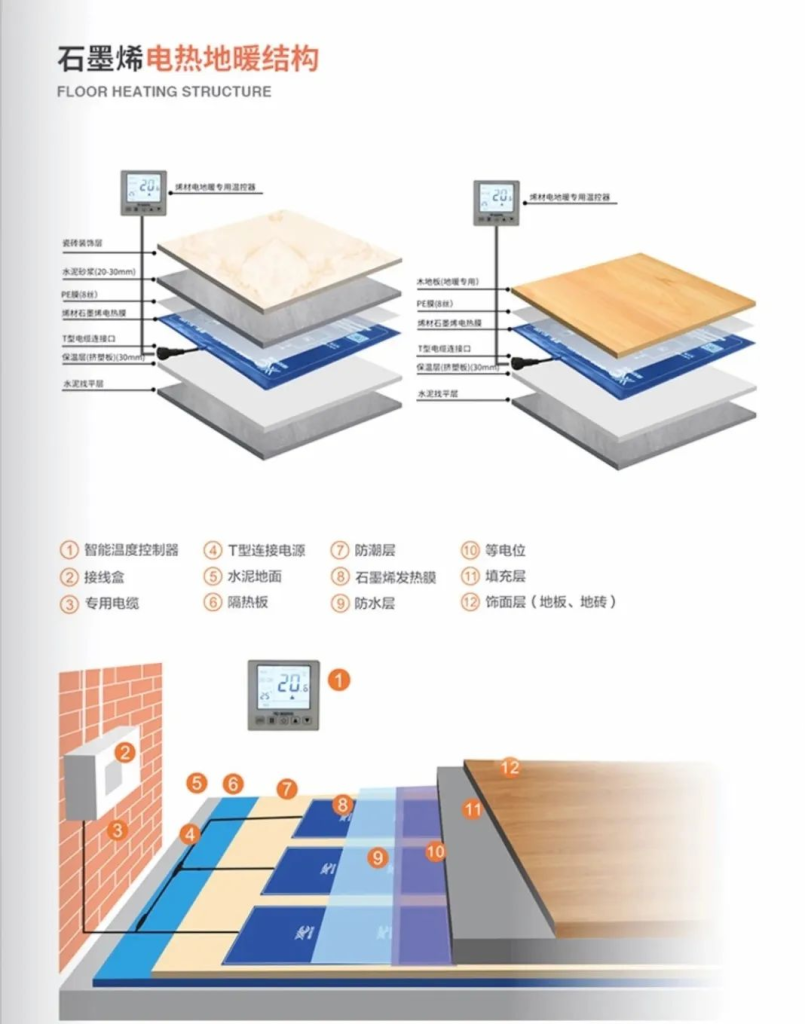

Despite the advantages of electric heating film for underfloor heating, there are still no comprehensive application standards. In contrast, heating cables are subject to the “Ground Radiant Heating Technology Code” (JGJ142-2004), approved and issued by the Ministry of Construction in 2004. Electric heating film manufacturers typically rely on either their own company standards or regional regulations.

A major concern is that many domestic electric heating film companies lack the expertise to design or install underfloor heating systems. They rush to market their products without collaborating with experts to ensure proper installation and maintenance. Some even confuse leakage current with electrical leakage and make inaccurate claims about product safety.

Key Issues Affecting Construction Quality

- Local Overheating: Overheating can occur when objects with poor heat conduction, such as blankets or heavy furniture, cover the heating surface. Electric heating films, especially those without flame-retardant properties, are more vulnerable to this than heating cables. Despite warnings in user manuals, it’s difficult for customers to avoid overheating completely.

- Electrical Safety: Electric heating films, as surface heating elements, can create a capacitive structure when installed under cement or mortar, resulting in capacitive leakage currents. While capacitive leakage current is inherent and harmless, electrical leakage caused by system damage is dangerous. Safety grounding and leakage protection are critical in preventing harm from electrical faults, but many manufacturers fail to implement these safeguards.

Unfortunately, most companies do not follow strict design and construction standards, leaving significant safety risks in their projects.

Unregulated Competition in the Electric Heating Film Industry

Unfair competition has led to unsafe cost-cutting measures, unrealistic promises, and poor-quality products. Many companies overpromise on product lifespan, energy consumption, and usage costs, which ultimately hurts the industry’s reputation.

Global Developments in Electric Heating Film

In countries like Japan and South Korea, electric heating film has been widely used for underfloor heating for years. Japan has established clear guidelines for insulation, wiring, and overheating protection, ensuring product safety. However, in China, early applications of electric heating film in ceiling heating systems led to issues such as inadequate indoor temperatures and high operational costs, resulting in customer complaints and legal disputes.

A Brighter Future for Electric Heating Film in Underfloor Heating

With the growing popularity of underfloor heating, electric heating film has the potential to become more prominent, especially with its eco-friendly and energy-efficient benefits. To capitalize on this, manufacturers must address technical challenges, follow strict design standards, and offer robust after-sales support.

By doing so, the future of electric heating film in the underfloor heating market looks promising.