Dispersion of Carbon Nanotubes – Challenges and Solutions

You can learn how to disperse carbon nanotubes (CNTs), understand the challenges of aggregation, explore surfactants and functionalization techniques, and discover the best practices for achieving stable CNT dispersions.

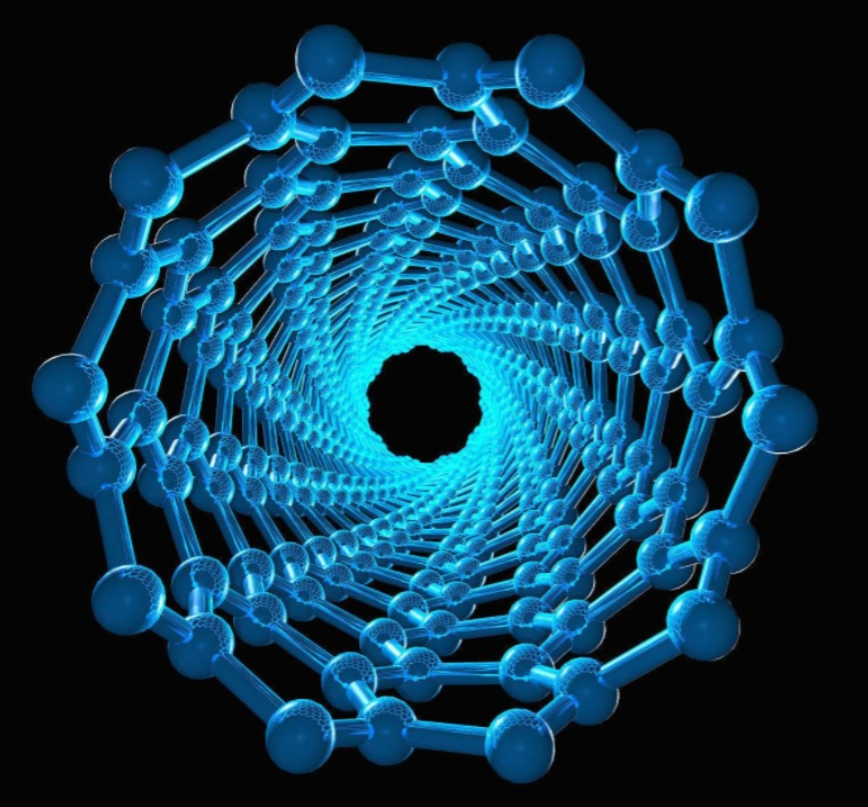

Carbon nanotubes (CNTs) — especially single-walled (SWCNTs) and multi-walled (MWCNTs) — have extraordinary electrical and mechanical properties. However, these benefits are only realized when the CNTs are individually dispersed in a medium.

Unfortunately, CNTs naturally bundle together due to van der Waals attractions, forming rope-like aggregates that limit performance. Dispersion is therefore a critical step in transforming CNT powders into usable forms for inks, coatings, composites, and films.

A well-dispersed CNT system ensures uniform electrical pathways, smooth coatings, and strong interfacial adhesion with host materials.

Why CNT Dispersion Is Difficult

CNTs are long, thin, and flexible, with a high aspect ratio (>1000). Their curved surfaces and π–π interactions cause them to stick together.

Challenges include:

-

Strong van der Waals attraction

-

Limited wettability in most solvents

-

Tendency to re-agglomerate during drying

-

Difficult visualization and quality control

Dispersion Methods

1. Ultrasonication

-

High-frequency sound waves break CNT bundles into smaller units.

-

Common for lab-scale dispersion.

-

Risk: Excessive sonication shortens tubes and damages structure.

2. High-Shear Mixing

-

Uses strong mechanical forces to mix CNTs into polymer matrices.

-

Ideal for viscous materials like epoxies and elastomers.

3. Three-Roll Milling

-

Provides controlled dispersion and alignment for conductive pastes.

-

Common in high-end CNT ink manufacturing.

4. Ball Milling (for industrial scale)

-

Breaks large aggregates but can introduce structural defects.

Solvents and Dispersing Agents

| Category | Example | Function |

|---|---|---|

| Aqueous surfactants | SDS, SDBS, Triton X-100 | Stabilize CNTs in water |

| Organic solvents | NMP, DMF, THF | Good dispersion for pristine CNTs |

| Polymers | PVP, PEG, PVDF | Prevent re-agglomeration |

| Ionic liquids | Imidazolium-based ILs | Excellent for stable dispersions |

| Bile salts | Sodium cholate | Gentle stabilization for SWCNTs |

Functionalization for Better Dispersion

1. Covalent Functionalization

Introduces chemical groups on the CNT surface (–COOH, –OH, –NH₂) to enhance solubility and compatibility.

-

Advantage: Improved bonding with polymers.

-

Limitation: Slightly reduces conductivity.

2. Non-Covalent Functionalization

Adsorbs surfactants, polymers, or aromatic molecules onto the CNT surface.

-

Advantage: Maintains electrical properties.

-

Common in conductive ink and coating formulations.

3. Hybrid Approach

Combines mild covalent modification with surfactant stabilization for high-performance dispersions.

Applications of CNT Dispersions

1. Conductive Coatings

Used for antistatic layers, transparent electrodes, and EMI shielding.

2. Polymer Composites

Enhanced tensile strength and conductivity at low CNT loadings (0.1–2 wt%).

3. Energy Devices

Used in lithium-ion batteries, supercapacitors, and fuel cell electrodes as conductive additives.

4. Sensors

CNT dispersions enable thin, sensitive films for gas, strain, or chemical sensing.

5. 3D Printing & Inks

Provide electrical pathways in printed circuits and flexible electronics.

What to Consider When Buying CNT Dispersions

-

Type: SWCNT or MWCNT-based.

-

Solvent System: Water, ethanol, NMP, DMF.

-

Concentration: 0.1–2 wt% typical for coatings.

-

Functionalization: Carboxylated or pristine.

-

Conductivity: >10³ S/m for high-performance inks.

-

Purity: Metal content <5%.

-

Stability: Should remain uniform for ≥6 months.

-

Price (2025):

-

Research-grade: $150–$500 per 100 mL

-

Industrial-grade: $200–$600/L

-

How to Prepare and Use CNT Dispersions

Step 1. Check container for sediment; gently stir or ultrasonicate before use.

Step 2. Mix with polymers or binders using high-shear blending.

Step 3. Avoid overheating during sonication.

Step 4. Apply via coating, dip, or spray methods.

Step 5. Dry under mild conditions to prevent re-agglomeration.

Step 6. Store sealed, away from moisture and heat.

Top CNT Dispersion Products in 2025

#1 CNT-Disp™ (SWCNT Dispersion)

-

Solvent: NMP

-

Conductivity: >10⁴ S/m

-

Application: Conductive films & inks

-

Price: $350–$500 per 100 mL

#2 AquaCNT™ (Water-Based CNT Dispersion)

-

Surfactant stabilized

-

Long-term shelf life

-

Ideal for antistatic coatings

-

Price: $250–$400/L

#3 CNT-MixPro™ (Polymer-Integrated Dispersion)

-

Pre-dispersed CNTs in epoxy or PU base

-

Ready for industrial composites

-

Price: $300–$600/kg

Dispersion is the most important step in transforming carbon nanotubes from powder into functional materials. Whether used for conductive coatings, energy devices, or composites, mastering dispersion chemistry and processing ensures performance and stability.

With the right combination of solvent, surfactant, and mechanical method, even the most stubborn CNT aggregates can be tamed into uniform, high-performance materials.

After reading this guide, are you ready to turn tangled nanotubes into advanced technologies?