Electromagnetic Interference Shielding Materials for Aerospace Electronics

Introduction to Electromagnetic Interference (EMI) in Aerospace Electronics

In the aerospace industry, electronic systems play a crucial role in the performance, safety, and functionality of aircraft and spacecraft. These systems include communication, navigation, control, and monitoring devices that must operate reliably in highly demanding environments. However, these electronic systems are vulnerable to electromagnetic interference (EMI), which can disrupt their normal operation and compromise mission-critical tasks.

Electromagnetic interference refers to the unwanted disturbance or noise that can affect the operation of electronic circuits and systems, often caused by external electromagnetic fields from other electronic devices, power sources, or natural sources like solar radiation. In the aerospace sector, EMI is especially concerning because it can cause malfunctions in sensitive avionics, radar, GPS, and communication systems, jeopardizing flight safety and mission success.

As a result, EMI shielding materials are essential in aerospace electronics to protect these systems from both internal and external sources of electromagnetic radiation. This article explores the various materials used for EMI shielding in aerospace electronics, with a focus on advanced materials like carbon nanotubes (CNTs) and their role in enhancing shielding effectiveness.

The Importance of EMI Shielding in Aerospace Electronics

Aerospace electronics are designed to function in harsh and often unpredictable environments. They are exposed to a variety of potential sources of EMI, including:

- External Sources: Lightning strikes, cosmic radiation, other aircraft, and satellite communication systems.

- Internal Sources: Electronic components within the aircraft or spacecraft itself, such as power supplies, electrical circuits, and propulsion systems.

The primary objective of EMI shielding is to prevent unwanted electromagnetic radiation from penetrating sensitive electronic systems, while also ensuring that the devices do not emit interfering radiation that could affect other systems. Effective EMI shielding not only ensures the proper functioning of electronic equipment but also complies with regulations and standards set by aviation authorities.

Materials for EMI Shielding

Various materials have been developed to address the challenges of EMI shielding in aerospace electronics. These materials generally fall into two categories:

- Conductive Materials: These materials block electromagnetic radiation by reflecting or absorbing the waves through their conductive properties.

- Magnetic Materials: These materials shield against EMI by using their magnetic properties to absorb electromagnetic waves and convert them into heat.

1. Metals (Traditional EMI Shielding Materials)

Metals like aluminum, copper, and steel have long been used as EMI shielding materials due to their excellent conductive properties. Metal-based shields can reflect or absorb electromagnetic waves, thus providing effective protection for sensitive electronics.

- Aluminum: Lightweight, corrosion-resistant, and cost-effective, aluminum is widely used in aerospace applications for EMI shielding. It provides good attenuation of electromagnetic waves and is relatively easy to fabricate.

- Copper: Known for its superior conductivity, copper is effective in blocking a wide range of frequencies. However, it is heavier and more expensive than aluminum.

- Steel: Steel-based shields are often used in aerospace systems for their robustness and durability, although they are less effective than aluminum and copper in terms of shielding efficiency.

While metal-based shields are still widely used, they have limitations in terms of weight, flexibility, and mechanical properties, particularly in the context of modern lightweight and high-performance aerospace materials.

2. Conductive Polymers

Conductive polymers are emerging as alternative materials for EMI shielding in aerospace electronics. These materials offer a lightweight, flexible, and corrosion-resistant solution, making them ideal for aerospace applications where weight and durability are critical.

- Polypyrrole (PPy) and Poly(3,4-ethylenedioxythiophene) (PEDOT): These conductive polymers can be processed into films, coatings, or composites for EMI shielding. While their conductivity is lower than metals, they offer advantages in flexibility and formability, which are essential for certain aerospace components.

- Polymer Composites with Conductive Fillers: Incorporating conductive fillers such as carbon black, graphene, or carbon nanotubes (CNTs) into polymers significantly enhances their EMI shielding properties. These composites are lighter and more versatile than metal shields, while still offering effective protection against EMI.

3. Carbon Nanotubes (CNTs) and Graphene-Based Materials

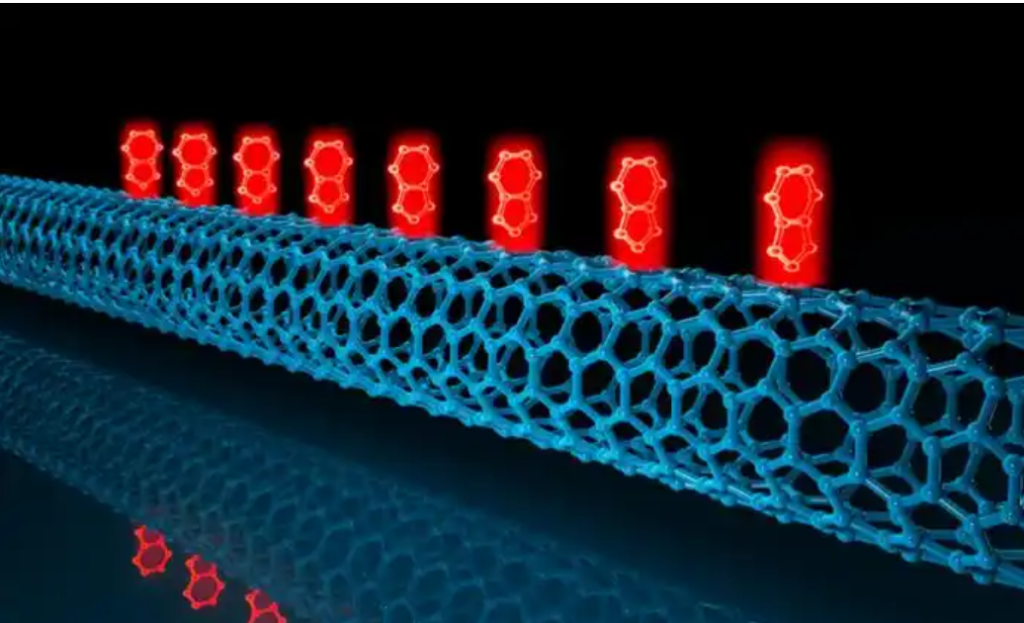

Carbon nanotubes and graphene have garnered significant attention as next-generation materials for EMI shielding, especially in the aerospace sector. CNTs are cylindrical nanostructures composed of carbon atoms arranged in a hexagonal lattice, while graphene is a two-dimensional sheet of carbon atoms with remarkable electrical, mechanical, and thermal properties.

- CNTs for EMI Shielding: CNTs are highly conductive materials that can be incorporated into various substrates such as polymers, resins, and composites. The unique structure of CNTs allows them to form a highly interconnected network within the material, enhancing its electrical conductivity and providing excellent EMI shielding effectiveness. The high surface area and mechanical strength of CNTs also make them ideal for lightweight aerospace applications.

- Graphene for EMI Shielding: Similar to CNTs, graphene exhibits extraordinary electrical conductivity and can be used in thin films or coatings for EMI shielding. Graphene-based materials are particularly attractive for aerospace applications due to their lightweight nature and high flexibility, which is essential for materials that need to conform to complex shapes and structures.

4. Metal Matrix Composites (MMCs)

Metal matrix composites, which combine metals like aluminum or copper with reinforcement materials such as CNTs, graphene, or ceramics, are also gaining popularity in EMI shielding applications. The addition of CNTs or graphene to metals improves their conductivity, mechanical strength, and thermal stability, making MMCs ideal for aerospace systems where both EMI shielding and mechanical performance are required.

Advantages of Carbon Nanotubes (CNTs) in EMI Shielding

1. Exceptional Conductivity

One of the key advantages of CNTs is their outstanding electrical conductivity. CNTs have been shown to possess electrical conductivity higher than that of traditional metals like copper, making them ideal for EMI shielding applications. When incorporated into composites, CNTs create conductive pathways that significantly enhance the material’s ability to block electromagnetic radiation.

2. Lightweight and High Strength

CNTs are extremely lightweight, which is crucial in aerospace applications where weight is a major concern. Their high tensile strength also ensures that the materials remain durable and robust even in the face of mechanical stresses, vibration, and temperature fluctuations that are common in aerospace environments.

3. Flexibility and Formability

CNTs can be easily integrated into various substrates, including polymers, resins, and coatings. This flexibility allows for the creation of lightweight, thin, and flexible shielding materials that can be applied to irregular surfaces and components. This is particularly advantageous for aerospace components that require complex geometries.

4. Thermal and Mechanical Stability

CNTs offer exceptional thermal stability, which is important in aerospace applications exposed to extreme temperatures, from the high heat of engine compartments to the freezing cold of high altitudes or outer space. Their mechanical properties, including high tensile strength and elasticity, ensure that CNT-based shielding materials can withstand the stresses encountered during flight.

5. Reduced Weight and Enhanced Performance

By incorporating CNTs into aerospace electronics, manufacturers can reduce the weight of shielding materials without compromising on performance. This weight reduction translates to fuel savings, higher payload capacities, and improved overall performance of the aircraft or spacecraft.

Challenges and Future Outlook

While CNTs offer many advantages in EMI shielding, there are still challenges that need to be addressed for their widespread adoption in aerospace applications:

- Cost: The production of CNTs can be expensive, and large-scale manufacturing processes need to be developed to make them more cost-effective for commercial use.

- Dispersion: Ensuring uniform dispersion of CNTs within composites can be difficult, and poor dispersion may reduce the effectiveness of the shielding material. Advanced dispersion techniques need to be employed to overcome this challenge.

- Long-Term Durability: The long-term stability and performance of CNT-based EMI shielding materials must be further evaluated to ensure their reliability in harsh aerospace environments.

Conclusion

Electromagnetic interference shielding is critical for the proper functioning and safety of aerospace electronics. Traditional materials like metals and conductive polymers have been widely used, but carbon nanotubes (CNTs) and graphene-based materials are emerging as highly promising alternatives due to their exceptional conductivity, lightweight nature, and mechanical strength. The incorporation of CNTs into EMI shielding materials for aerospace applications provides significant advantages in terms of performance, durability, and weight reduction. As research progresses, CNT-based materials will likely become a cornerstone of next-generation aerospace systems, enabling safer, more efficient, and reliable electronics in both aircraft and spacecraft.