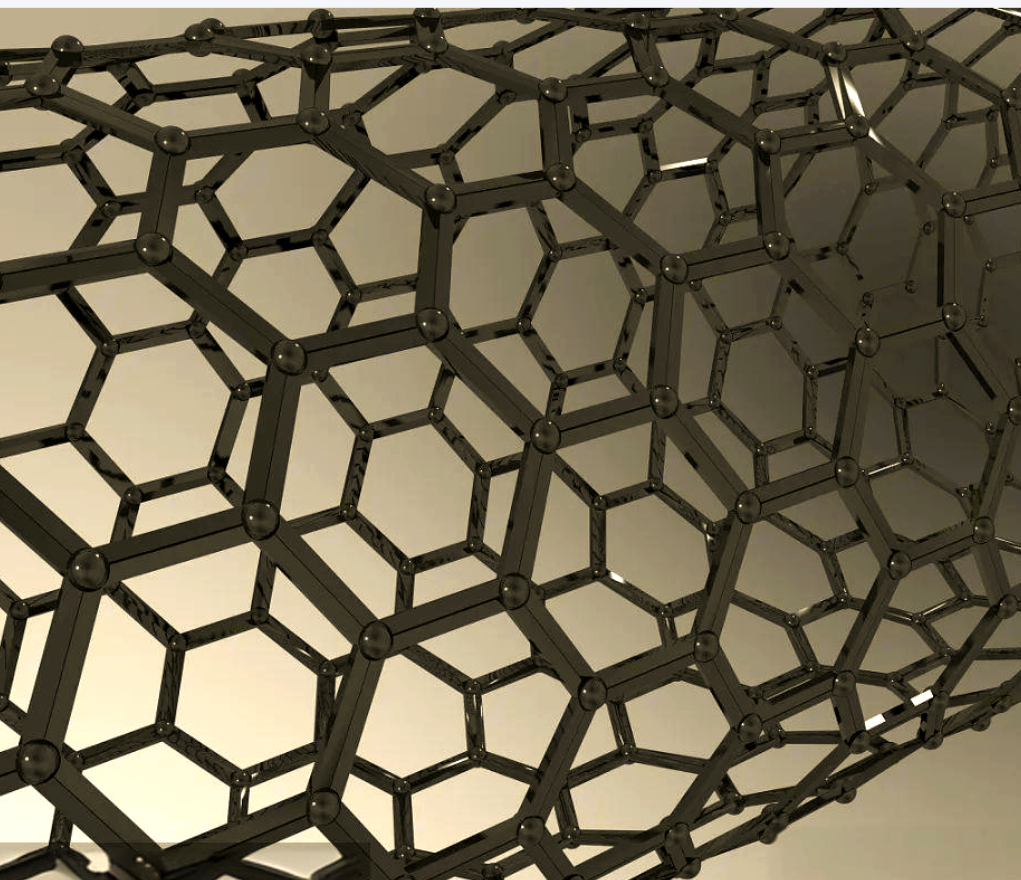

Enhancing Electrode Performance in Sodium-Ion and Lithium-Sulfur Batteries with Carbon Nanotubes

As global energy demands shift toward safer, more efficient, and sustainable energy storage technologies, sodium-ion batteries (SIBs) and lithium-sulfur (Li–S) batteries have emerged as promising alternatives to traditional lithium-ion batteries. However, both systems face significant performance limitations — including low electrical conductivity, poor cycle stability, and volume expansion during cycling. One material offering solutions to these challenges is carbon nanotubes (CNTs).

This article explores how carbon nanotubes enhance the performance of both cathode and anode materials in sodium-ion and lithium-sulfur batteries, making them more viable for commercial and high-performance applications.

1. Role of Carbon Nanotubes in Next-Generation Battery Systems

Carbon nanotubes, due to their unique one-dimensional tubular structure and exceptional electrical, mechanical, and chemical properties, are highly effective in addressing key bottlenecks in advanced battery chemistries. Key advantages include:

-

High electrical conductivity

-

Large specific surface area

-

Excellent mechanical strength and flexibility

-

Ability to form 3D conductive networks

-

Stability in harsh electrochemical environments

By incorporating CNTs into electrode architectures, both SIBs and Li–S batteries experience improved charge transport, faster reaction kinetics, and reduced degradation over time.

2. Carbon Nanotubes in Sodium-Ion Batteries (SIBs)

Challenges in SIBs:

Sodium-ion batteries suffer from larger ionic radius of Na⁺ (~1.02 Å vs. Li⁺ ~0.76 Å), leading to sluggish diffusion kinetics, limited intercalation host materials, and mechanical stress during cycling.

CNT Applications in Anodes:

-

CNT/Hard Carbon Composites: CNTs are often blended with hard carbon to improve the electrical conductivity and buffer the volume changes during Na⁺ insertion/extraction.

-

CNT/Metal Oxide Hybrids: Metal oxides like Fe₂O₃ or TiO₂ used as SIB anodes benefit from CNT scaffolds that enhance electron transport and prevent particle agglomeration.

Example: A CNT-TiO₂ hybrid anode showed improved rate performance and longer cycle life compared to pure TiO₂ due to the conductive CNT network and stress-relieving flexibility.

CNT Applications in Cathodes:

-

CNT/Na₃V₂(PO₄)₃ Composites: CNT coatings or networks around cathode particles facilitate faster electron movement, improving specific capacity and cycle retention.

-

CNTs as 3D Conductive Networks: Embedding cathode materials in a CNT matrix reduces internal resistance and enhances structural stability.

Result: CNT-modified SIB cathodes demonstrate improved rate performance even at high current densities and maintain >85% capacity after 1000+ cycles.

3. Carbon Nanotubes in Lithium–Sulfur Batteries (Li–S)

Challenges in Li–S Batteries:

-

Insulating nature of sulfur and discharge product (Li₂S)

-

Large volume expansion (~80%) during cycling

-

Polysulfide shuttle effect causing rapid capacity fading

Carbon nanotubes help mitigate all these issues through confinement, conductivity enhancement, and structural stability.

CNT Applications in Sulfur Cathodes:

-

CNT-Sulfur Composites: Sulfur embedded in CNT matrices benefits from improved electron pathways and active material utilization.

-

CNT Coatings: Coating cathodes with CNTs creates a barrier layer that traps polysulfides, minimizing the shuttle effect.

-

Hierarchical Porous CNT Frameworks: These can physically trap LiPS (lithium polysulfides) and chemically anchor them with functional groups or dopants.

Example: A nitrogen-doped CNT–S composite cathode displayed >1200 mAh/g capacity over 200 cycles with minimal degradation.

CNT Applications in Li Metal Anodes:

-

Suppressing Dendrite Formation: CNT interlayers can guide uniform Li deposition and suppress dendritic growth, improving safety.

-

Conductive Scaffolds: CNT mats serve as hosts for lithium metal, accommodating volume changes and reducing SEI layer instability.

Result: Enhanced Coulombic efficiency and extended cycle life compared to bare Li anodes.

4. Advantages of CNT Integration

| Feature | Sodium-Ion Batteries | Lithium–Sulfur Batteries |

|---|---|---|

| Improved Conductivity | Better rate performance | Enables electron transport in S cathode |

| Structural Integrity | Buffers volume change in anode | Accommodates S volume expansion |

| Shuttle Effect Mitigation | Not applicable | Suppresses polysulfide migration |

| Cycling Stability | >1000 cycles achievable | 500–1000 cycles with minimal fading |

| Scalable Fabrication | Compatible with slurry processes | Spray, dip-coating, vacuum filtration |

5. Fabrication Methods for CNT-Based Electrodes

Several fabrication techniques are used to integrate CNTs into battery electrodes:

-

Slurry Casting: Mixing CNTs with active materials and binders for electrode coating on metal foils.

-

Vacuum Filtration: Forming free-standing CNT composite films.

-

Electrospinning: Creating CNT/polymer nanofiber mats as flexible electrodes.

-

CVD (Chemical Vapor Deposition): Directly growing CNT networks on current collectors or active materials.

Each method has trade-offs in terms of scalability, cost, and electrode performance, but slurry casting remains the most industry-compatible.

6. Commercial and Research Outlook

Sodium-Ion Batteries:

While SIBs are not yet mass-produced like LIBs, their lower cost and abundant sodium sources make them attractive for grid storage and stationary applications. CNTs will play a critical role in advancing electrode materials and enabling competitive performance.

Lithium–Sulfur Batteries:

Li–S batteries are nearing commercialization, especially in aerospace, drones, and electric aviation, where high energy density and lightweight design are essential. CNT-based electrodes are a foundational technology for these high-performance Li–S systems.

7. Conclusion

Carbon nanotubes are revolutionizing the design and functionality of electrodes in both sodium-ion and lithium-sulfur batteries. From enhancing electronic conductivity to stabilizing active materials during cycling, CNTs serve as a multi-functional material that directly addresses the critical shortcomings of these next-generation battery technologies.

As research continues and fabrication techniques improve, CNT-enhanced battery systems are expected to transition from laboratory innovations to commercially viable energy storage solutions — powering the future of clean and reliable energy.