Enhancing Tire Wear Resistance and Conductivity with Carbon Nanotubes

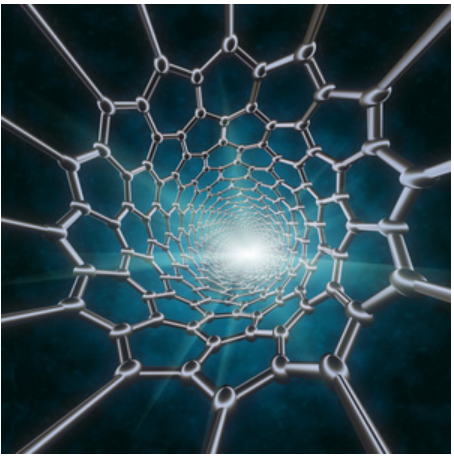

Carbon nanotubes (CNTs) are revolutionizing tire technology by improving wear resistance, durability, and electrical conductivity. These properties contribute to longer-lasting, more energy-efficient, and safer tires, which are essential for modern vehicles, including electric vehicles (EVs) and autonomous cars.

1. Challenges in Modern Tire Technology

✔ Key Issues in Traditional Tires:

-

High wear rate → Frequent replacements and increased costs.

-

Low conductivity → Buildup of static electricity, affecting safety.

-

Rolling resistance → Increases fuel consumption or reduces EV range.

-

Environmental concerns → Tire microplastics contribute to pollution.

✔ Why Carbon Nanotubes?

-

Exceptional wear resistance → Extends tire lifespan.

-

High electrical conductivity → Prevents static buildup.

-

Lightweight reinforcement → Improves fuel efficiency.

-

Sustainability potential → Reduces raw material consumption.

2. CNTs for Enhanced Wear Resistance in Tires

✔ Role of CNTs in Rubber Reinforcement:

-

CNTs strengthen the polymer matrix, reducing material breakdown.

-

High aspect ratio of CNTs forms an interconnected network, enhancing toughness.

-

CNTs prevent microcracks from propagating, reducing tread wear.

✔ Comparison of Tire Wear with and without CNTs:

| Tire Type | Wear Resistance | Lifespan | Rolling Resistance |

|---|---|---|---|

| Traditional Tires | Moderate | ~40,000-60,000 km | High |

| CNT-Enhanced Tires | High | Up to 100,000 km | Reduced |

✔ Real-World Impact:

-

Tires last 50-100% longer, reducing replacement frequency.

-

Lower rolling resistance improves fuel efficiency and extends EV range.

3. Improving Electrical Conductivity with CNTs

✔ Why Conductivity Matters in Tires?

-

Prevents static charge buildup, which can cause sparks and safety hazards.

-

Essential for modern EVs and autonomous vehicles, which rely on tire-based sensors.

✔ CNTs as Conductive Fillers:

-

Even at low concentrations (0.5-2%), CNTs create a conductive network in rubber.

-

Maintains flexibility and elasticity, unlike traditional conductive additives.

✔ Practical Applications:

-

Safe static discharge → Reduces explosion risks in fuel transport.

-

Smart tires → Enhances data collection for autonomous driving.

-

Better grounding in EVs → Improves overall electrical system performance.

4. CNTs vs. Traditional Reinforcement Fillers

| Material | Strength Improvement | Conductivity | Environmental Impact |

|---|---|---|---|

| Carbon Black | Good | Low | High emissions |

| Silica | Moderate | Low | Less sustainable |

| Carbon Nanotubes (CNTs) | Excellent | High | Lower material usage |

✔ CNTs offer superior reinforcement and conductivity without increasing material weight.

✔ Less material is needed compared to carbon black, reducing overall environmental impact.

5. Future Outlook: CNTs in Next-Gen Smart and Sustainable Tires

✔ Self-Healing Tires: CNT-reinforced rubber can help develop self-repairing tire materials.

✔ Energy-Generating Tires: CNTs enable piezoelectric effects, turning road friction into electricity.

✔ Recyclable Tires: CNT-based composites improve tire recyclability and reduce waste.

6. Conclusion: The Future of CNT-Enhanced Tires

✔ Higher durability → Reduces wear, extending tire lifespan.

✔ Enhanced conductivity → Essential for modern EVs and autonomous cars.

✔ Lower rolling resistance → Improves energy efficiency.

✔ Eco-friendly impact → Less material usage and fewer emissions.

Carbon nanotubes are shaping the next generation of smart, efficient, and long-lasting tires. With advancements in nanotechnology, CNT-enhanced tires could become the new standard for both commercial and high-performance vehicles. 🚗⚡