Environmental and Sustainability Aspects of Single-Walled Carbon Nanotubes (SWCNTs): Opportunities and Challenges

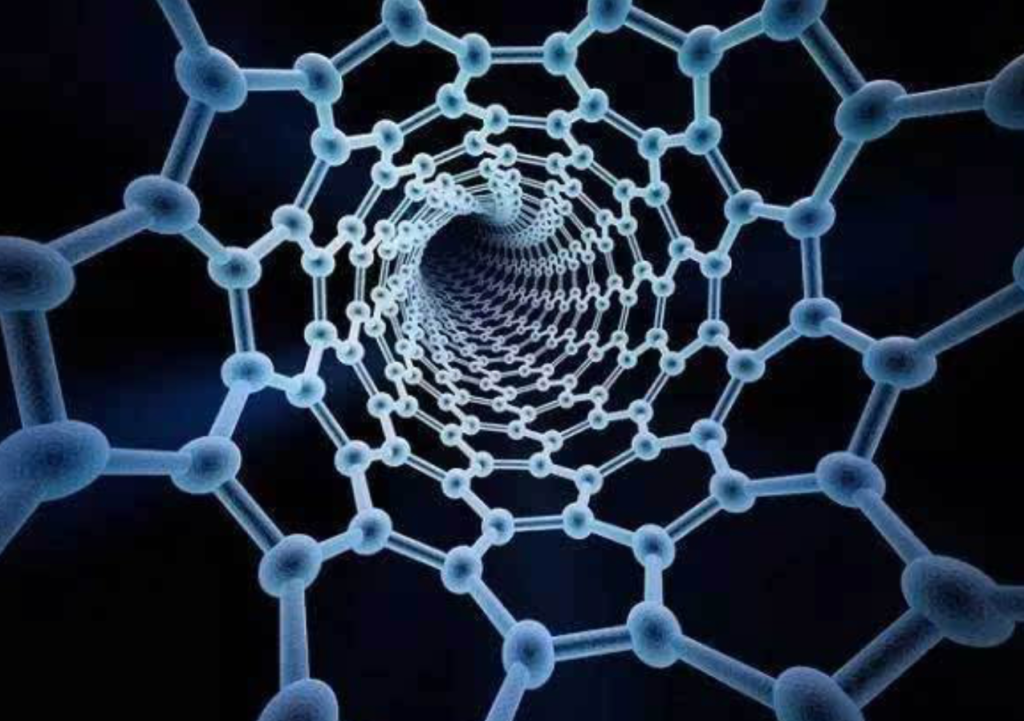

Single-walled carbon nanotubes (SWCNTs) are lauded for their exceptional mechanical, electrical, and thermal properties, making them a cornerstone material in advanced technologies such as energy storage, electronics, and nanomedicine. However, as their production and applications expand, concerns about their environmental footprint and long-term sustainability arise. This article explores the environmental impact of SWCNTs throughout their lifecycle—from production to application and disposal—and examines strategies to develop more sustainable production techniques.

1. Environmental Impact of SWCNT Production

1.1. Resource-Intensive Processes

Producing SWCNTs often requires significant energy input and the use of chemical precursors. The two primary methods—chemical vapor deposition (CVD) and arc discharge—have environmental drawbacks:

- Chemical Vapor Deposition (CVD):

- High-temperature processes consume substantial energy, leading to a high carbon footprint.

- Catalysts like transition metals (e.g., nickel, cobalt) are often non-renewable and can generate waste during extraction and disposal.

- Hydrocarbon feedstocks, commonly used in CVD, contribute to greenhouse gas emissions during production.

- Arc Discharge and Laser Ablation:

- Both methods rely on high-energy setups, making them less sustainable for large-scale production.

- These processes may produce by-products, including amorphous carbon and residual catalysts, that require disposal.

1.2. Toxicity of By-Products

- The production of SWCNTs often results in chemical by-products such as carbon soot, metallic residues, and volatile organic compounds (VOCs). Improper management of these by-products can contaminate air, water, and soil, posing risks to ecosystems and human health.

1.3. Challenges in Scale-Up

Scaling up SWCNT production to meet industrial demand while maintaining quality consistency exacerbates environmental issues. Energy-intensive processes and inefficient material usage contribute to higher waste generation and emissions.

2. Environmental Impacts of SWCNT Applications

While SWCNTs have significant potential to contribute to green technologies, their applications also raise concerns:

2.1. Beneficial Applications with Environmental Trade-Offs

- Energy Storage Systems:

SWCNTs improve the efficiency of batteries, supercapacitors, and fuel cells, which can reduce reliance on fossil fuels. However, manufacturing these devices involves energy-intensive processes that may offset their environmental benefits. - Water Filtration and Purification:

SWCNT-based membranes show promise in removing pollutants from water. Despite this, producing such membranes may involve hazardous chemicals, and their disposal at the end of life remains a challenge. - Lightweight Composites in Transportation:

SWCNTs in composites reduce the weight of vehicles and aircraft, leading to lower fuel consumption. However, recycling these composites at the end of their lifecycle is not yet well-established.

2.2. Toxicity in Biomedical Applications

SWCNTs have shown promise in drug delivery, imaging, and biosensors. However:

- Potential Health Risks: Some studies indicate that SWCNTs can induce cytotoxicity, oxidative stress, or inflammation in biological systems if not properly functionalized.

- Environmental Exposure: Accidental release of SWCNTs during use or disposal could lead to contamination of ecosystems, with unknown long-term effects.

3. Environmental Challenges in SWCNT Disposal

3.1. Lack of Recycling Infrastructure

- SWCNTs and SWCNT-containing products are often difficult to recycle due to their chemical stability and integration with other materials. For instance:

- Composites and Coatings: SWCNTs embedded in polymers or composites cannot be easily separated, resulting in non-recyclable waste.

- Electronic Devices: Recovering SWCNTs from flexible electronics or transparent films is technologically complex and economically unfeasible.

3.2. Risks of Nanoparticle Pollution

- If improperly managed, SWCNTs can enter the environment during disposal, potentially causing harm to aquatic life, soil organisms, and plants. Their nano-scale size allows them to penetrate biological membranes, leading to bioaccumulation.

3.3. Degradation Concerns

- SWCNTs are highly resistant to degradation under natural conditions, which raises concerns about their persistence in the environment.

4. Opportunities for Sustainable SWCNT Production and Use

4.1. Renewable Feedstocks

- Biomass-Derived Carbon Sources: Using renewable materials like plant-derived hydrocarbons or agricultural waste as feedstocks for SWCNT production can reduce reliance on fossil fuels. This approach not only lowers carbon emissions but also supports circular economy models.

4.2. Green Catalysts

- Developing non-toxic, recyclable catalysts (e.g., iron-based catalysts) can minimize the environmental impact of SWCNT synthesis. Catalysts that can be easily recovered and reused after production further enhance sustainability.

4.3. Energy-Efficient Production Techniques

- Low-Temperature Processes: Advancements in low-temperature synthesis methods could significantly reduce energy consumption.

- Solar-Assisted Synthesis: Utilizing renewable energy sources, such as solar power, to heat reactors in CVD processes can cut emissions.

4.4. Improved Waste Management

- Catalyst Recycling: Recovery and reuse of metal catalysts can minimize solid waste.

- By-Product Utilization: Finding secondary applications for by-products like amorphous carbon can reduce waste.

5. Ensuring Sustainable Application and Disposal

5.1. Functionalization to Reduce Toxicity

- Proper surface functionalization of SWCNTs can reduce their toxicity in biomedical and environmental applications. Coating SWCNTs with biocompatible materials or modifying their surface chemistry can make them safer for use.

5.2. Design for Recycling

- Developing SWCNT-based materials with recyclability in mind can reduce waste. For example:

- Designing composites that allow for easy separation of SWCNTs.

- Exploring pyrolysis or chemical methods to recover SWCNTs from end-of-life products.

5.3. Lifecycle Assessment (LCA)

- Comprehensive LCAs for SWCNT products can identify hotspots in production and use, enabling the development of more sustainable practices.

5.4. Regulatory Oversight

- Establishing guidelines for the safe handling, use, and disposal of SWCNTs can mitigate environmental and health risks.

6. Conclusion

Single-walled carbon nanotubes (SWCNTs) present tremendous opportunities for advancing technologies in energy, electronics, medicine, and more. However, their production, application, and disposal raise significant environmental and sustainability challenges. To maximize their potential while minimizing environmental impact, stakeholders must prioritize green production methods, develop recyclable designs, and implement robust waste management systems.

By adopting sustainable practices, SWCNTs can be integrated into a future where high-performance materials coexist with environmental stewardship, driving innovation without compromising the planet. As research continues, collaboration between industry, academia, and policymakers will be essential to fully realize the promise of SWCNTs in a sustainable and responsible manner.