Fatigue Resistance and Heat Tolerance of Carbon Nanotube-Reinforced Composites

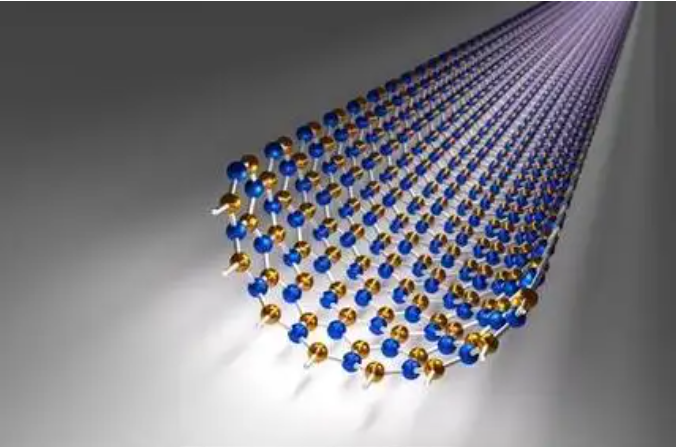

Carbon nanotubes (CNTs) have established themselves as one of the most promising materials for enhancing the performance of composites, particularly in demanding applications. Among the most critical attributes required in advanced materials are resistance to fatigue and tolerance to high temperatures. Carbon nanotube-reinforced composites (CNTRCs) are at the forefront of addressing these challenges, offering unparalleled mechanical strength, thermal stability, and durability. This article delves into the fatigue resistance and heat tolerance of CNTRCs, exploring their mechanisms, applications, and future prospects.

Understanding Fatigue Resistance in CNT-Reinforced Composites

Fatigue is a phenomenon where materials weaken or fail after repeated cyclic loading, even if the applied stresses are below their ultimate tensile strength. This is a primary concern for structural materials used in aerospace, automotive, and other industries where reliability under cyclic stresses is paramount.

Mechanisms of Fatigue Resistance

CNTs contribute to fatigue resistance in composites through the following mechanisms:

- Load Transfer Efficiency: CNTs, due to their exceptional tensile strength (up to 100 GPa), serve as nanoscale reinforcements that distribute applied loads more evenly within the matrix. This reduces stress concentrations, which are often the precursors of fatigue cracks.

- Crack Bridging and Arrest: CNTs act as bridges across developing cracks, inhibiting their propagation. Their ability to absorb and redistribute energy delays the onset of catastrophic failure.

- Energy Dissipation: During cyclic loading, CNTs dissipate energy through reversible deformation and interfacial friction between CNTs and the matrix, reducing damage accumulation.

- Interfacial Strength: Functionalized CNTs form strong bonds with the matrix material, enhancing interfacial adhesion and preventing debonding under repeated stresses.

Applications Benefiting from Fatigue Resistance

CNTRCs are already being employed or studied for use in fatigue-critical applications such as:

- Aerospace Components: Wing structures, fuselage panels, and turbine blades.

- Automotive Parts: Suspension systems, chassis, and drive shafts.

- Sports Equipment: High-performance bicycles, tennis rackets, and skis.

- Wind Turbines: Blades subjected to cyclic loading from wind forces.

Case Studies and Performance Improvements

Research has demonstrated that CNTRCs exhibit significantly improved fatigue life compared to conventional composites. For instance, studies on epoxy-CNT composites show an increase in fatigue life by up to 50% compared to neat epoxy systems.

Heat Tolerance of CNT-Reinforced Composites

High-temperature performance is another critical requirement for materials used in aerospace, energy, and automotive sectors. CNTRCs excel in this area, leveraging the exceptional thermal properties of CNTs.

Mechanisms of Heat Tolerance

The heat tolerance of CNTRCs can be attributed to the following factors:

- High Thermal Conductivity: CNTs possess thermal conductivities in the range of 3000-5000 W/m·K, far exceeding traditional materials. When embedded in a matrix, CNTs enhance heat dissipation, preventing localized thermal degradation.

- Thermal Stability: CNTs maintain their structural integrity at temperatures exceeding 2000°C in inert atmospheres. This contributes to the overall stability of CNTRCs under high-temperature conditions.

- Barrier Effects: CNTs act as barriers to the diffusion of oxygen and other reactive species into the matrix, delaying thermal oxidation and degradation.

- Matrix Stabilization: CNTs restrict the mobility of polymer chains in thermosetting matrices, raising the glass transition temperature (Tg) and improving thermal resistance.

Applications Benefiting from Heat Tolerance

The ability of CNTRCs to perform under extreme temperatures makes them ideal for:

- Aerospace Applications: Thermal protection systems, leading edges, and engine components.

- Automotive Systems: Engine covers, exhaust systems, and brake components.

- Electronics: Heat sinks and thermal management systems in high-performance devices.

- Energy Systems: Components in concentrated solar power systems and fuel cells.

Case Studies and Performance Improvements

Studies have shown that CNTs can raise the thermal decomposition temperature of polymer composites by 50-100°C. For instance, CNT-reinforced phenolic resins demonstrate enhanced heat resistance, making them suitable for ablative materials in re-entry vehicles.

Challenges in CNTRC Development

Despite their remarkable properties, several challenges must be addressed for the broader adoption of CNTRCs:

- Cost of Production: The synthesis and purification of high-quality CNTs remain expensive, limiting their commercial viability.

- Dispersion and Alignment: Achieving uniform dispersion and alignment of CNTs within the matrix is critical to realizing their full potential. Poor dispersion can lead to agglomeration, reducing performance.

- Interfacial Bonding: Strong interfacial bonding between CNTs and the matrix is essential for effective load transfer and thermal conductivity. Functionalization techniques must balance bonding with the preservation of CNT properties.

- Scalability: Manufacturing processes for CNTRCs must be scalable and reproducible to meet industrial demands.

Future Directions

Research and development efforts are focused on overcoming these challenges and unlocking the full potential of CNTRCs. Promising approaches include:

- Advanced Functionalization: Techniques to enhance interfacial bonding without compromising CNT properties.

- Hybrid Composites: Combining CNTs with other nanomaterials, such as graphene, to achieve synergistic effects.

- Automated Manufacturing: Developing scalable processes, such as automated fiber placement (AFP) and additive manufacturing, for CNTRCs.

- Cost Reduction: Innovations in CNT production methods, such as chemical vapor deposition (CVD), to lower costs.

Conclusion

Carbon nanotube-reinforced composites represent a paradigm shift in material science, offering exceptional fatigue resistance and heat tolerance. These properties make CNTRCs indispensable for advanced applications in aerospace, automotive, energy, and beyond. While challenges remain, ongoing research and technological advancements are poised to make CNTRCs more accessible and impactful. As these materials continue to evolve, they will undoubtedly play a crucial role in shaping the future of high-performance composites.