Fatigue Resistance and Thermal Durability of Carbon Nanotube-Reinforced Composites

Carbon nanotube (CNT)-reinforced composites represent a groundbreaking advancement in materials science, offering exceptional fatigue resistance and thermal durability. These composites combine the extraordinary mechanical and thermal properties of CNTs with the versatility of polymeric, metallic, or ceramic matrices, making them indispensable in high-performance applications.

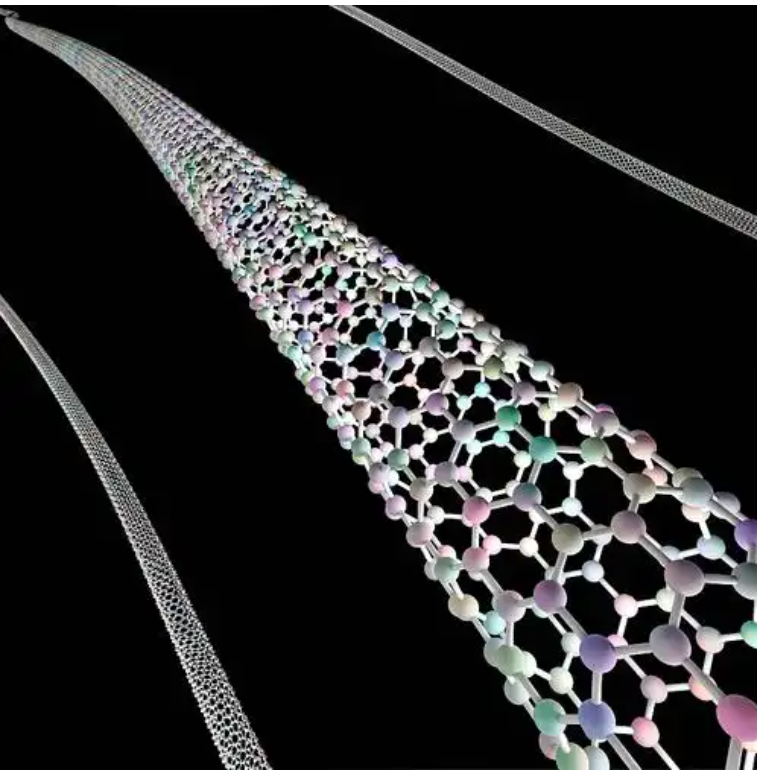

Introduction to Carbon Nanotube-Reinforced Composites

Carbon nanotubes are nanoscale cylindrical structures made of rolled-up graphene sheets. They exhibit remarkable properties such as high tensile strength (up to 100 GPa), low density, excellent thermal conductivity (approximately 3,000 W/m·K), and superior chemical stability. When incorporated into a composite matrix, CNTs enhance the material’s mechanical and thermal properties significantly.

Fatigue Resistance: Mechanisms and Advantages

Fatigue resistance is a critical factor in determining a material’s durability under cyclic loading. CNT-reinforced composites exhibit exceptional fatigue resistance due to the following mechanisms:

- Load Transfer Efficiency: CNTs act as micro-scale reinforcements within the matrix, effectively distributing stress and reducing localized deformation. This load transfer mechanism delays crack initiation and propagation.

- Crack Bridging: CNTs bridge micro-cracks in the matrix, preventing them from growing under cyclic stress. This enhances the composite’s ability to withstand repeated loading.

- Energy Dissipation: The high aspect ratio of CNTs allows them to dissipate energy through pull-out and sliding mechanisms, which mitigates fatigue damage.

- Matrix Toughening: CNTs improve the matrix’s toughness, enabling it to absorb more energy before failure. This is particularly beneficial for polymer-based composites.

Applications Highlighting Fatigue Resistance

- Aerospace: Wing and fuselage components subject to repetitive stress.

- Automotive: Suspension systems and drive shafts in high-performance vehicles.

- Wind Energy: Turbine blades designed for long operational lifespans under cyclic loading.

Thermal Durability: Mechanisms and Advantages

CNT-reinforced composites are known for their remarkable thermal stability and resistance to high-temperature environments. The following properties contribute to their thermal durability:

- Thermal Conductivity: CNTs have exceptional thermal conductivity, which aids in dissipating heat across the composite and prevents localized thermal degradation.

- Thermal Expansion Coefficient: The low coefficient of thermal expansion (CTE) of CNTs minimizes thermal stresses within the composite, reducing the likelihood of thermal fatigue.

- Oxidation Resistance: CNTs are chemically stable and resist oxidation at elevated temperatures, extending the composite’s lifespan in harsh environments.

- Matrix Reinforcement: By reinforcing the matrix, CNTs enhance its thermal decomposition temperature, enabling the composite to maintain structural integrity under extreme conditions.

Applications Highlighting Thermal Durability

- Electronics: Heat sinks and thermal interface materials for high-power devices.

- Aerospace: Rocket nozzles and thermal protection systems.

- Energy: High-temperature fuel cells and nuclear reactor components.

Challenges and Solutions

Despite their advantages, CNT-reinforced composites face challenges such as:

- Dispersion: Achieving uniform dispersion of CNTs within the matrix is difficult. Advanced techniques such as ultrasonic mixing and surfactant-assisted dispersion are being employed to address this issue.

- Interfacial Bonding: Strong interfacial bonding between CNTs and the matrix is crucial for effective load transfer. Functionalization of CNTs and the use of coupling agents can enhance bonding.

- Cost: The high cost of CNTs limits their widespread adoption. Scaling up production and developing cost-effective synthesis methods are ongoing efforts to reduce costs.

Future Prospects

The development of CNT-reinforced composites is a rapidly evolving field. Emerging trends include:

- Hybrid Composites: Combining CNTs with other nanomaterials like graphene or nanoclays to achieve synergistic effects.

- Self-Healing Composites: Incorporating self-healing mechanisms to further enhance fatigue resistance.

- 3D Printing: Utilizing additive manufacturing techniques to create CNT-reinforced structures with tailored properties.

Conclusion

Carbon nanotube-reinforced composites offer unparalleled fatigue resistance and thermal durability, making them ideal for demanding applications in aerospace, automotive, electronics, and energy sectors. While challenges such as dispersion and cost remain, ongoing research and technological advancements promise to unlock the full potential of these revolutionary materials. Their unique properties are poised to redefine the limits of modern engineering and materials science.