Fe-Al Substrate + Graphene – Cost-Effective Heating for Construction & Household Applications

The demand for efficient, durable, and cost-effective heating solutions in construction and household applications has driven innovation in graphene-based heating technologies.

One of the most promising approaches combines graphene layers with Fe-Al (iron-aluminum) alloy substrates, delivering rapid, uniform heating with excellent mechanical stability and long-term reliability.

This article explores the technology behind Fe-Al + graphene heating systems, their advantages over traditional heaters, and their applications in building heating, household appliances, and industrial settings.

1. Introduction to Fe-Al Substrate + Graphene Heating

Graphene is renowned for its high electrical and thermal conductivity, flexibility, and mechanical strength.

When integrated with Fe-Al substrates, the result is a robust, low-resistance heating panel suitable for large-area and high-volume applications.

Why Fe-Al Substrate?

-

High thermal stability: Fe-Al alloys maintain structural integrity at elevated temperatures.

-

Excellent corrosion resistance: Aluminum content improves oxidation resistance.

-

Mechanical strength: Provides a durable base for flexible or laminated graphene films.

-

Cost-effectiveness: Fe-Al alloys are more economical than copper or stainless steel while delivering comparable thermal performance.

2. Structure and Working Principle

An Fe-Al + graphene heating element typically consists of:

-

Fe-Al Substrate: Acts as a structural base and heat distributor.

-

Graphene Layer: Deposited via CVD, spray coating, or screen printing, forming a conductive network that converts electricity into heat.

-

Insulating Layer or Protective Coating: Ensures safety and uniform temperature distribution.

-

Electrodes: Copper or silver busbars connect the graphene layer to a low-voltage power source.

How It Works

-

When electrical current flows through the graphene layer, Joule heating occurs.

-

Heat spreads efficiently into the Fe-Al substrate due to its high thermal conductivity (~50–120 W/m·K depending on composition).

-

The combination ensures uniform surface temperature with rapid warm-up times.

3. Advantages of Fe-Al + Graphene Heating Systems

3.1 High Heating Efficiency

Graphene’s low resistivity enables rapid heating with minimal energy loss.

Fe-Al substrates enhance heat distribution, preventing localized hot spots common in traditional resistive heaters.

3.2 Uniform Temperature Distribution

The thermal conductivity of the Fe-Al substrate ensures even heat transfer across the panel surface.

Temperature variations are typically ±2°C, suitable for both household comfort and precise construction heating.

3.3 Mechanical Strength and Durability

-

Fe-Al alloys resist warping, corrosion, and mechanical deformation.

-

Graphene layers maintain conductivity under repeated bending, thermal cycling, and mechanical stress.

-

Long operational life (>20,000 heating cycles) ensures reliable performance.

3.4 Lightweight and Thin Form Factor

Compared to traditional heating plates, Fe-Al + graphene panels are lighter, thinner, and easier to integrate into flooring, wall panels, and appliances.

3.5 Safe Low-Voltage Operation

-

Designed for DC or low-voltage AC applications (typically 12–48 V DC).

-

Graphene’s self-limiting heating behavior reduces overheating risk.

-

Protective coatings prevent electrical contact, moisture ingress, and corrosion.

3.6 Cost-Effective

-

Fe-Al alloys are readily available and lower-cost than copper or nickel substrates.

-

Reduced material usage and simplified fabrication methods make graphene + Fe-Al systems economically attractive for construction and household projects.

4. Manufacturing and Fabrication Techniques

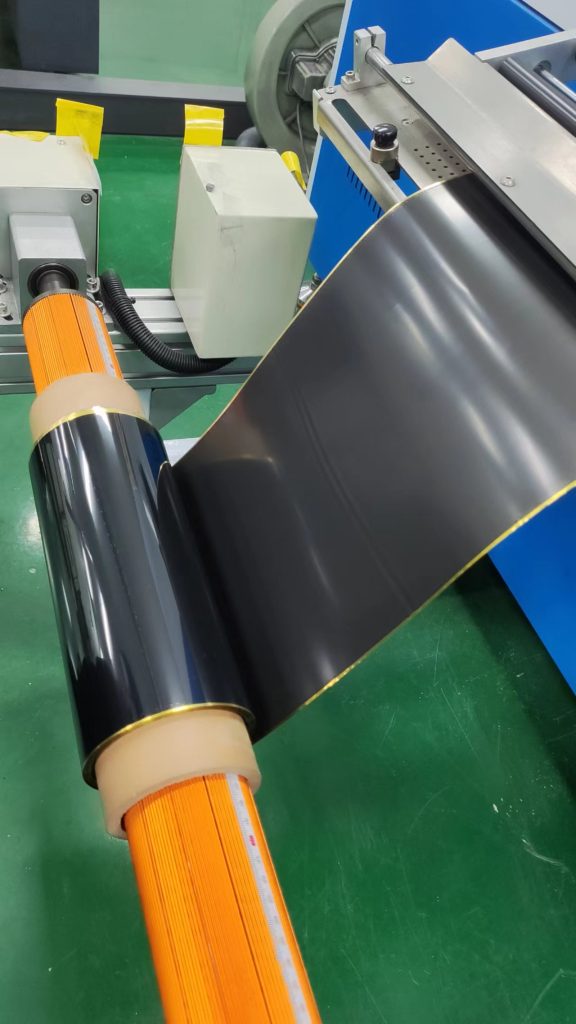

4.1 Graphene Deposition

Graphene can be integrated onto Fe-Al substrates using:

-

Chemical Vapor Deposition (CVD): Produces high-quality monolayer graphene on metal foils.

-

Spray Coating or Screen Printing: Deposits graphene flakes or inks for scalable production.

-

Roll-to-Roll Lamination: Ideal for large-area heating panels.

4.2 Electrode Attachment

-

Copper or silver busbars are affixed at edges to ensure stable electrical contact.

-

Flexible conductive adhesives may be used to maintain panel flexibility.

4.3 Protective Layer Integration

-

Optional polymer or ceramic coatings improve durability, electrical insulation, and moisture resistance.

-

Transparent coatings can be applied for applications requiring visual aesthetics.

5. Applications in Construction and Household

5.1 Floor and Wall Heating

Fe-Al + graphene panels provide efficient radiant heating for:

-

Residential and commercial flooring

-

Under-wall or ceiling panels

-

Office partitions and heated floors in cold climates

Benefits include even warmth, rapid response, and thin installation profiles, allowing integration without structural modification.

5.2 Household Appliances

Graphene heating on Fe-Al substrates is used in:

-

Electric cooktops and ovens

-

Hair dryers, irons, and toasters

-

Heated towel rails and bathroom panels

Key advantages: faster warm-up, energy efficiency, and long lifespan.

5.3 De-Icing and Snow-Melting Systems

Fe-Al + graphene heaters can be embedded in:

-

Driveways, stairs, or ramps for snow and ice prevention

-

Roof panels or gutters to prevent ice formation

-

Greenhouse heating systems for controlled plant environments

The combination of uniform heat distribution and durability ensures effective operation even in harsh outdoor conditions.

5.4 Industrial and Workshop Heating

-

Tool warming, soldering stations, and localized workspace heating

-

Quick thermal response allows energy-efficient spot heating

-

Fe-Al substrate resists mechanical wear in industrial environments

6. Thermal and Electrical Performance Characteristics

| Parameter | Typical Value | Remarks |

|---|---|---|

| Operating Voltage | 12–48 V DC | Low-voltage design for safety |

| Surface Temperature | 40–80°C | Adjustable via current control |

| Heat-up Time | 5–15 seconds | Rapid response |

| Thermal Conductivity | 50–120 W/m·K | Depends on Fe-Al composition |

| Mechanical Life | >20,000 cycles | High durability under thermal cycling |

| Sheet Resistance | 10–50 Ω/sq | Graphene layer optimized for uniform heating |

These metrics demonstrate the efficiency, safety, and durability of Fe-Al + graphene heating systems for both consumer and industrial use.

7. Advantages Over Traditional Heating Technologies

| Feature | Fe-Al + Graphene Heater | Traditional Wire/Metal Heater |

|---|---|---|

| Heating Uniformity | Excellent | Often uneven |

| Energy Efficiency | High (>90%) | Moderate (70–80%) |

| Warm-Up Time | Seconds | Minutes |

| Mechanical Durability | Very high | Moderate |

| Integration Flexibility | Thin, lightweight | Bulkier |

| Corrosion Resistance | Excellent | Moderate |

| Maintenance | Minimal | Moderate to high |

The combination of graphene and Fe-Al substrate outperforms conventional resistive heaters in durability, efficiency, and installation flexibility.

8. Safety Considerations

-

Fe-Al + graphene heaters are designed for low-voltage operation, reducing shock risk.

-

Insulation layers prevent accidental contact with the conductive graphene layer.

-

Temperature sensors and control circuits ensure stable operation and prevent overheating.

-

Corrosion-resistant Fe-Al substrates extend lifetime and reliability, even in humid or damp environments.

9. Industrial Trends and Future Development

9.1 Large-Area Panel Manufacturing

Roll-to-roll deposition and screen printing of graphene on Fe-Al panels enable high-volume production for construction-scale heating systems.

9.2 Integration with Smart Home Systems

-

Wi-Fi or Bluetooth-enabled controllers

-

Smart thermostats with energy-optimized heating schedules

-

Integration with solar or battery-powered systems for energy efficiency

9.3 Hybrid Graphene Composites

Combining graphene with CNTs or metallic nanowires can enhance thermal conductivity and electrical stability for high-power applications.

9.4 Sustainable Construction Heating

Graphene + Fe-Al systems reduce energy consumption, support renewable energy integration, and minimize installation footprint compared with traditional radiator or resistance wire systems.

Fe-Al substrate combined with graphene presents a cost-effective, durable, and energy-efficient heating solution for both construction and household applications.

Key advantages include:

-

Rapid and uniform heating

-

High mechanical and thermal durability

-

Low-voltage, safe operation

-

Easy integration into floors, walls, appliances, and industrial heating systems

As production methods and graphene deposition technologies advance, Fe-Al + graphene heaters are poised to replace traditional resistive heating solutions, offering smarter, more efficient, and long-lasting thermal management in residential, commercial, and industrial settings.