Fire Resistant Paint Formulations with Graphene Oxide

Mechanisms, Formulation Strategies, and Performance Advantages

Introduction: Why Fire-Resistant Coatings Need Smarter Fillers

Fire-resistant paints play a critical role in protecting buildings, industrial equipment, and infrastructure by delaying ignition, slowing flame spread, and reducing heat transfer.

Traditional flame-retardant coatings rely heavily on:

-

High loading of inorganic fillers

-

Halogenated or phosphorus-based additives

-

Intumescent systems with limited durability

These approaches often compromise mechanical strength, adhesion, flexibility, and long-term stability.

In recent years, Graphene Oxide (GO) has emerged as a next-generation functional additive that enables fire resistance with lower loading and multifunctional performance.

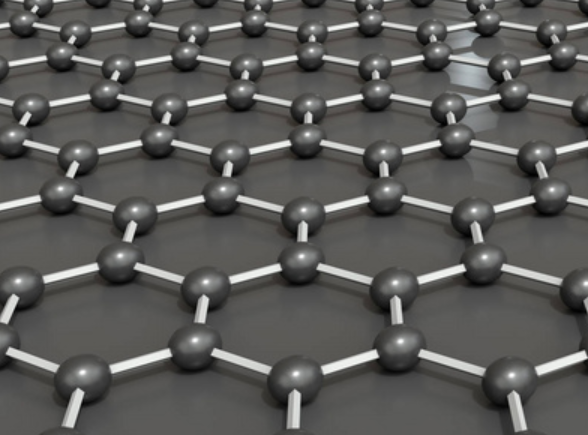

What Makes Graphene Oxide Different?

Graphene Oxide is a two-dimensional carbon material with:

-

High aspect ratio nanosheets

-

Oxygen-containing functional groups (–OH, –COOH, epoxy)

-

Excellent dispersion compatibility in waterborne and solvent systems

Unlike traditional flame retardants, GO does not primarily act by releasing flame-quenching gases.

Instead, it works through physical and structural fire-protection mechanisms.

Fire Resistance Mechanisms of Graphene Oxide

1. Physical Barrier Effect

When exposed to heat or flame, GO nanosheets:

-

Align and overlap within the coating

-

Form a tortuous diffusion path for heat, oxygen, and combustible gases

This significantly slows:

-

Heat penetration into the substrate

-

Oxygen diffusion toward the fire source

The result is delayed ignition and reduced flame spread.

2. Char Formation Enhancement

Graphene Oxide promotes:

-

Stable, continuous char layers

-

Dense carbonaceous residues after combustion

In intumescent systems, GO:

-

Reinforces the expanding char structure

-

Prevents cracking and collapse of the protective layer

This improves fire endurance time and structural integrity during fire exposure.

3. Synergy with Traditional Flame Retardants

GO shows strong synergistic effects with:

-

Ammonium polyphosphate (APP)

-

Melamine-based systems

-

Phosphorus–nitrogen flame retardants

By reinforcing the char network, GO allows:

-

Reduced loading of conventional flame retardants

-

Lower smoke density

-

Improved coating durability

Formulation Strategies for GO-Based Fire-Resistant Paints

Recommended GO Loading Levels

Typical effective loading:

-

0.1–1.0 wt% (based on total formulation)

Even at very low concentrations, GO can significantly enhance fire performance when well dispersed.

Compatible Coating Systems

Graphene Oxide is especially suitable for:

-

Waterborne acrylic paints

-

Epoxy fire-protection coatings

-

Intumescent architectural coatings

-

Cementitious and hybrid inorganic–organic systems

Its surface functional groups enable strong interaction with polymer binders and inorganic fillers.

Dispersion Considerations

Key formulation points:

-

Use pre-dispersed GO slurries where possible

-

Avoid aggressive high-shear that fragments nanosheets

-

Add GO during early dispersion stages for network formation

Proper dispersion is critical to achieving continuous barrier structures.

Performance Benefits Beyond Fire Resistance

One of GO’s strongest advantages is multifunctionality.

In addition to fire resistance, GO-enhanced coatings often show:

-

Improved adhesion to metal and concrete substrates

-

Reduced crack propagation

-

Lower gas and moisture permeability

-

Enhanced corrosion resistance

-

Improved mechanical integrity after thermal cycling

This makes GO particularly attractive for long-life industrial and infrastructure coatings.

Comparison with Conventional Flame-Retardant Fillers

| Parameter | Conventional FR Fillers | Graphene Oxide |

|---|---|---|

| Typical Loading | 15–40 wt% | 0.1–1 wt% |

| Fire Mechanism | Chemical / gas-phase | Physical barrier + char |

| Effect on Mechanical Properties | Often negative | Often positive |

| Smoke Suppression | Limited | Improved |

| Coating Density | High | Minimal impact |

| Multifunctionality | Low | High |

Application Areas

Graphene Oxide fire-resistant paints are especially suited for:

-

Structural steel fire protection

-

Industrial equipment and pipelines

-

Tunnels and transportation infrastructure

-

Battery enclosures and energy systems

-

Marine and offshore installations

These applications benefit from thin coatings with long-term stability, where traditional high-loading systems struggle.

Regulatory and Testing Considerations

GO-enhanced coatings are typically evaluated using:

-

Limiting Oxygen Index (LOI)

-

Cone calorimetry

-

Flame spread index tests

-

Smoke density measurements

Importantly, GO acts as a performance enhancer, not a regulated flame-retardant chemical, simplifying compliance in many regions.

Future Outlook

As fire safety standards become more stringent and sustainability concerns grow, the industry is shifting toward:

-

Lower additive loading

-

Halogen-free formulations

-

Multifunctional coating systems

Graphene Oxide aligns naturally with these trends and is expected to play a growing role in next-generation fire-resistant paint technologies.

Graphene Oxide enables a new design logic for fire-resistant paints—less material, smarter structure, and broader performance.

By reinforcing barrier effects and char stability at low loading, GO allows formulators to achieve fire protection without sacrificing mechanical durability or processability.

For advanced fire-resistant coatings, Graphene Oxide is no longer just an additive—it is a structural design element.