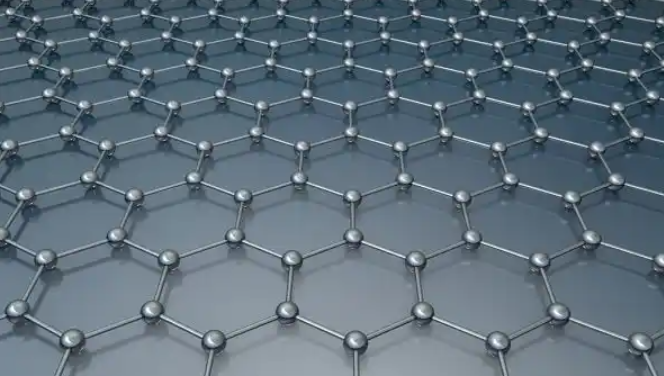

Functionalized Graphene: How Chemical Groups Enhance Material Performance

Functionalized graphene has become one of the most important categories in graphene technology. By introducing chemical groups onto the graphene surface, its compatibility, processability, dispersibility, electrical properties, and application range are greatly improved. In this beginner-friendly guide, you will learn what functionalized graphene is, why it matters, how it is modified, and how to select the right product for industrial applications.

Overview

Graphene is widely known for its superb conductivity, strength, and thermal properties. However, pristine graphene has limited industrial use due to:

-

Hydrophobic surfaces

-

Agglomeration tendencies

-

Poor dispersibility in most solvents and polymers

-

Weak bonding with matrices

Functionalization solves these issues by attaching reactive chemical groups to graphene:

-

Carboxyl (−COOH)

-

Hydroxyl (−OH)

-

Epoxy (−O−)

-

Amino (−NH₂)

-

Sulfonate (−SO₃H)

-

Other polymer grafts

As a result, functionalized graphene becomes easy to disperse, easy to bond, and easy to integrate into commercial materials.

Why Functionalization Is Important

| Key Improvement | Why It Matters |

|---|---|

| Better dispersion in water, ethanol, acetone | Enables coatings, inks, and additive manufacturing |

| Stronger interfacial bonding | Enhances mechanical properties in composites |

| Surface chemistry control | Enables sensing, catalysis, energy storage |

| Polymer compatibility | Useful in electronics, aerospace, packaging |

| Reduced agglomeration | Improves electrical and thermal conductivity |

Functionalization turns graphene from a premium additive into a universal material solution provider across many industries.

Types of Functionalized Graphene

1️⃣ Oxygen-Functionalized Graphene

-

Includes graphene oxide (GO), rGO, carboxyl graphene

-

Excellent for water dispersion

-

Strong chemical reactivity

Applications: inks, anti-corrosion coatings, EMI shielding

2️⃣ Nitrogen-Doped Graphene

-

Enhanced conductivity

-

High catalytic activity

Applications: batteries, fuel cells, supercapacitors

3️⃣ Amino-Functionalized Graphene

-

Strong bonding with resins and polymers

Applications: structural composites, epoxy adhesives

4️⃣ Polymer-Grafted Graphene

-

Customized interfacial compatibility

Applications: 3D printing filaments, rubber reinforcement

5️⃣ Alkyl/Organofunctional Graphene

-

Disperses in oils and non-polar matrices

Applications: lubricants, hydrophobic coatings

How Graphene Is Functionalized

Covalent Functionalization

Creates strong chemical bonds with graphene structure

✅ Best mechanical bonding

⚠ May reduce conductivity slightly

Common techniques:

-

Oxidation (Hummers method → GO)

-

Carboxylation

-

Amine grafting

-

Silane coupling

Non-Covalent Functionalization

Uses van der Waals forces or π–π interactions

✅ Conductivity preserved

⚠ Bonding not as strong

Examples:

-

Surfactants

-

Polymers (PVP, PEG)

-

Aromatic molecules (pyrene derivatives)

Industrial Applications

| Industry | Benefit | Example Use |

|---|---|---|

| Conductive coatings | Lower resistivity, thin films | EMI shielding |

| Polymers & plastics | +40% mechanical strength | Aerospace composite |

| Batteries / Supercapacitors | Higher capacity & cycle life | LFP, NCM cathodes |

| Anti-corrosion systems | Barrier layer protection | Marine steel |

| Thermal management | Heat dissipation | Mobile phones |

| 3D printing | Improved layer bonding | Electronics housings |

Functionalized graphene turns existing materials into high-performance composites.

What Should I Consider When Buying?

✔ Functional group type (COOH, NH₂, SO₃H, etc.)

✔ Dispersibility (water / ethanol / DMF / oils / resins)

✔ Sheet size (0.5–50 µm)

✔ Thickness (1–10 layers)

✔ Impurities or metal residues

✔ Form (powder, dispersion, slurry)

✔ Conductivity requirements

✔ Target application industry

📌 Typical pricing (2025)

-

Powder: $80–$300/kg (industrial grade)

-

Dispersion: $30–$120/L depending on wt%

-

Polymer masterbatch: $10–$60 per kg premium

How to Use Functionalized Graphene

Basic steps for operation:

-

Check form (powder vs slurry vs dispersion)

-

Use sonication for uniform dispersion

-

Add slowly to matrix under stirring

-

Optimize loading (usually 0.1–3 wt%)

-

Test film uniformity, conductivity, and bonding strength

-

Store sealed in dry environments

Functionalized graphene is the gateway for commercializing graphene at scale. Surface chemical groups enable:

-

Better dispersion

-

Improved compatibility

-

Stronger bonding

-

Expanded applications

With the right product selection and processing method, you can easily transform ordinary materials into next-generation high-performance composites.