Functionalized Textiles with Carbon Nanotubes: Revolutionizing the Fabric Industry

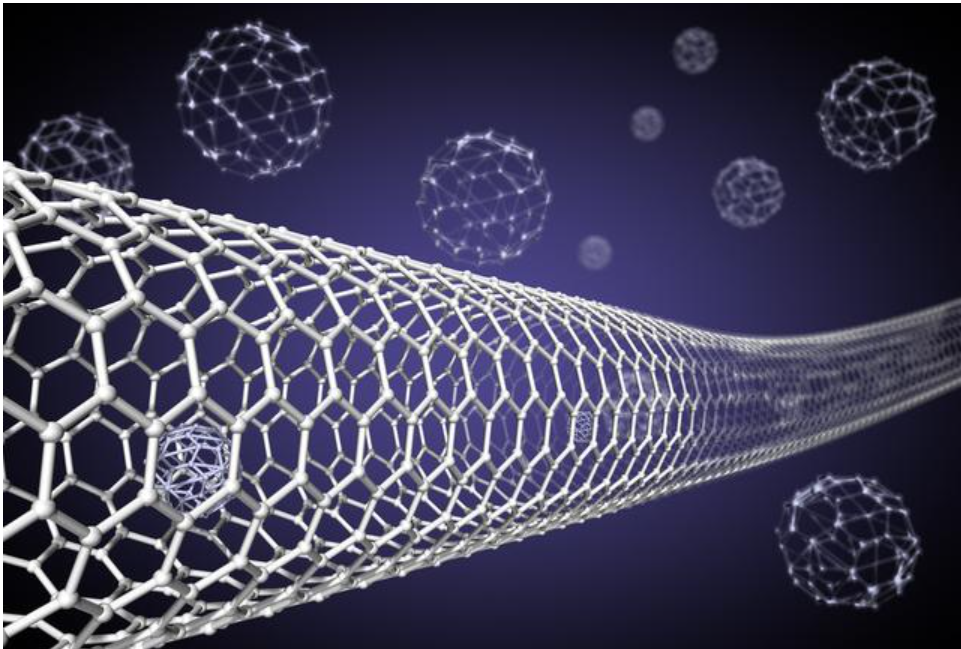

Carbon nanotubes (CNTs), with their remarkable mechanical, electrical, and thermal properties, are finding applications in textile functionalization. By integrating CNTs into fibers and fabrics, textiles can achieve advanced functionalities such as conductivity, antimicrobial properties, and water resistance, paving the way for innovative applications in wearable technology, healthcare, and protective gear.

This article explores the role of CNTs in textile functionalization, covering their unique properties, applications, real-world examples, market impact, and the challenges associated with their use.

Unique Properties of Carbon Nanotubes for Textiles

- Exceptional Conductivity

- CNTs possess electrical conductivity up to 10^6 S/m, enabling their use in creating conductive fabrics for electronic applications.

- Antibacterial Properties

- The large surface area and unique chemistry of CNTs can disrupt bacterial membranes, offering long-lasting antimicrobial effects.

- Hydrophobicity and Water Resistance

- Functionalized CNTs can form superhydrophobic surfaces, repelling water and other liquids effectively.

- Lightweight and Durable

- Despite being lightweight, CNTs are 100 times stronger than steel, enhancing the mechanical properties of textiles.

- Thermal Stability

- CNTs maintain their performance under extreme temperatures, making them suitable for high-performance applications.

Key Applications of CNTs in Functionalized Textiles

1. Conductive Textiles

- Application: Creating fabrics that can conduct electricity for wearable electronics and smart clothing.

- Example: CNT-infused fibers used in sensors for monitoring heart rate, temperature, and motion.

- Advantage: Flexible, washable, and highly durable conductive pathways.

2. Antimicrobial Textiles

- Application: Producing antibacterial fabrics for healthcare and hygiene applications.

- Example: Medical scrubs and bedding with CNT coatings to prevent microbial growth.

- Advantage: Long-lasting protection against bacteria and viruses without affecting fabric softness.

3. Water-Resistant and Self-Cleaning Textiles

- Application: Developing superhydrophobic and stain-resistant fabrics for outdoor and sportswear.

- Example: CNT-treated jackets that repel water and dirt, enhancing comfort and durability.

- Advantage: Improved water resistance without compromising breathability.

4. Flame-Resistant Textiles

- Application: Enhancing the fire resistance of textiles for industrial and protective use.

- Example: Firefighter uniforms coated with CNTs for improved thermal resistance and durability.

- Advantage: Lightweight and heat-resistant fabrics for enhanced safety.

5. Energy-Harvesting Textiles

- Application: Integrating energy storage and harvesting capabilities into fabrics.

- Example: CNT-based fabrics embedded with photovoltaic cells to power wearable devices.

- Advantage: Lightweight, portable, and eco-friendly power solutions.

Real-World Case Studies

1. Smart Clothing

- Researchers have developed CNT-coated fibers capable of measuring electrical signals from the body.

- Result: Enhanced user comfort with high sensitivity in detecting physiological parameters.

2. Antibacterial Bed Linens

- CNT-infused hospital linens have shown up to 99.9% bacterial reduction after repeated washes.

- Result: Improved hygiene and reduced hospital-acquired infections.

3. Outdoor Sportswear

- CNT-treated jackets and trousers with water-resistant and breathable properties are becoming popular among hikers and athletes.

- Result: Increased durability and comfort for outdoor enthusiasts.

Market Potential

The global smart textile market, which includes CNT-functionalized fabrics, is experiencing significant growth.

Market Drivers

- Rising demand for smart and wearable textiles.

- Growing awareness of hygiene and antimicrobial solutions.

- Increasing focus on sustainability and multifunctionality in the textile industry.

Market Projections

- The smart textile market is projected to grow at a CAGR of 20% from 2023 to 2030, with CNTs playing a critical role in high-performance segments.

Challenges in Using CNTs for Textiles

- High Production Costs

- CNTs are expensive to produce, which can impact the affordability of CNT-functionalized textiles.

- Dispersion and Uniformity

- Achieving even distribution of CNTs in fibers and fabrics is technically challenging and critical for consistent performance.

- Scalability

- Scaling CNT integration processes for mass production remains a bottleneck for large-scale applications.

- Environmental Concerns

- Potential health and environmental risks associated with CNTs require careful management and regulation.

- Durability of Functional Coatings

- Maintaining CNT properties after repeated washing and wear is a significant challenge for commercial textiles.

Future Directions

- Cost-Effective Production

- Innovations in CNT synthesis and processing methods are needed to reduce costs.

- Hybrid Functionalization

- Combining CNTs with other nanomaterials, such as graphene and silver nanowires, for enhanced performance.

- Advanced Coating Techniques

- Developing methods such as dip-coating and electrospinning for uniform CNT integration.

- Sustainability Focus

- Exploring bio-based CNT production and recyclable textiles for environmentally friendly solutions.

- Regulatory Compliance

- Establishing clear guidelines to ensure the safety of CNT-based textiles for consumers and workers.

Conclusion

Carbon nanotubes are revolutionizing the textile industry by enabling the development of multifunctional fabrics that combine advanced properties such as conductivity, antibacterial activity, and water resistance. Despite challenges in cost and scalability, the potential applications of CNTs in functionalized textiles are vast, ranging from smart clothing and medical fabrics to outdoor gear and industrial protective wear.

With continued advancements in CNT technology and integration methods, CNT-functionalized textiles are set to play a pivotal role in shaping the future of the textile industry.