“Graphene + AI” Empowering a Food Revolution! The World’s First 3D Cooking Printer Launched

A research team from the Hong Kong University of Science and Technology (HKUST) has unveiled the world’s first graphene-AI intelligent 3D food printer, achieving simultaneous food printing and high-temperature cooking. Utilizing a laser-induced graphene (LIG) infrared heating system, this technology integrates multiple traditional food manufacturing processes into a unified workflow, achieving revolutionary breakthroughs in food safety, energy consumption control, and shape retention. The integrated system developed by HKUST combines precise infrared heating with AI-driven design tools, overcoming key limitations in automated food production: maintaining food safety during printing and creating complex shapes without the need for professional expertise.

1. Technological Breakthroughs

Laser-Induced Graphene (LIG) Heater

- An ultra-thin polyimide film is laser-treated to form the LIG heating layer.

- Requires only 14 watts of ultra-low power, achieving precise temperature control at 137°C (compared to 1000–2000 watts for traditional ovens).

- Real-time layer-by-layer cooking, achieving over 99% surface sterilization; colony count after 48 hours is just 1/50 of the traditional method.

AI-Driven Design Revolution

- Users input text descriptions (e.g., “hollow gingerbread man”), and DALL-E generates a 3D model.

- Automatic conversion to printable files, enabling complex shape customization without modeling experience.

2. Performance Verification

Microscopic Structural Analysis

- Infrared-cooked samples exhibit uniform internal structure without the excessive expansion seen in traditional baking.

- X-ray analysis shows superior porosity distribution compared to ovens and air fryers.

Multi-Material Adaptation

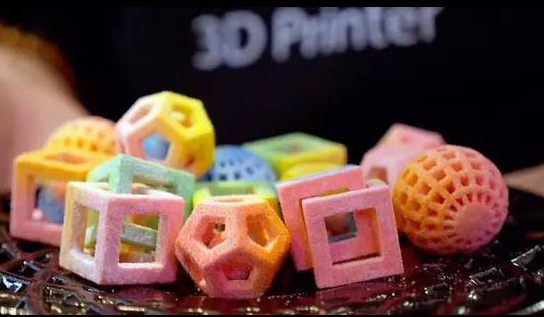

- Successfully printed starch-based cookies, vegetable purees, and protein materials with millimeter-level precision (less than 0.5 mm error for complex hollow structures).

3. Application Prospects

Medical Customization

- Precisely control food components and calories, offering sugar-free pastries tailored for diabetic patients.

- Postoperative liquid diets can achieve micron-level nutritional accuracy, supporting personalized recovery plans.

Commercial Kitchens

- One device = printing + cooking, reducing the footprint by 80%.

- Quick production of complex desserts in as little as 5 minutes for custom orders.

- Automated production in bakeries, reducing labor costs by 70%.

Aerospace and Military

- Real-time printing of high-energy food for field units, extending shelf life to 72 hours.

4. Advantages of Graphene Technology

The LIG heating module demonstrates three major features:

- Ultra-fast response: Heats up to 100°C in less than 5 seconds.

- Uniform surface heating: COMSOL simulations show a temperature variance of less than 2°C.

- Flexible integration: With a thickness of just 0.1 mm, it can adapt to any printing platform.

This breakthrough in graphene-AI-driven 3D food printing marks a transformative step toward intelligent, efficient, and sustainable food production.