Graphene Anticorrosive Coatings – Why They Last Longer

1. Corrosion Challenges Across Industries

Corrosion is a pervasive problem, affecting industries from automotive and aerospace to oil & gas, construction, and marine equipment. Traditional anticorrosive coatings often face limitations:

-

Micro-cracks and pinholes allow moisture penetration

-

Limited barrier efficiency against aggressive chemicals

-

Degradation under UV exposure or mechanical stress

Graphene, as an advanced two-dimensional nanomaterial, offers a fundamentally different approach to prolonging coating life and improving protection.

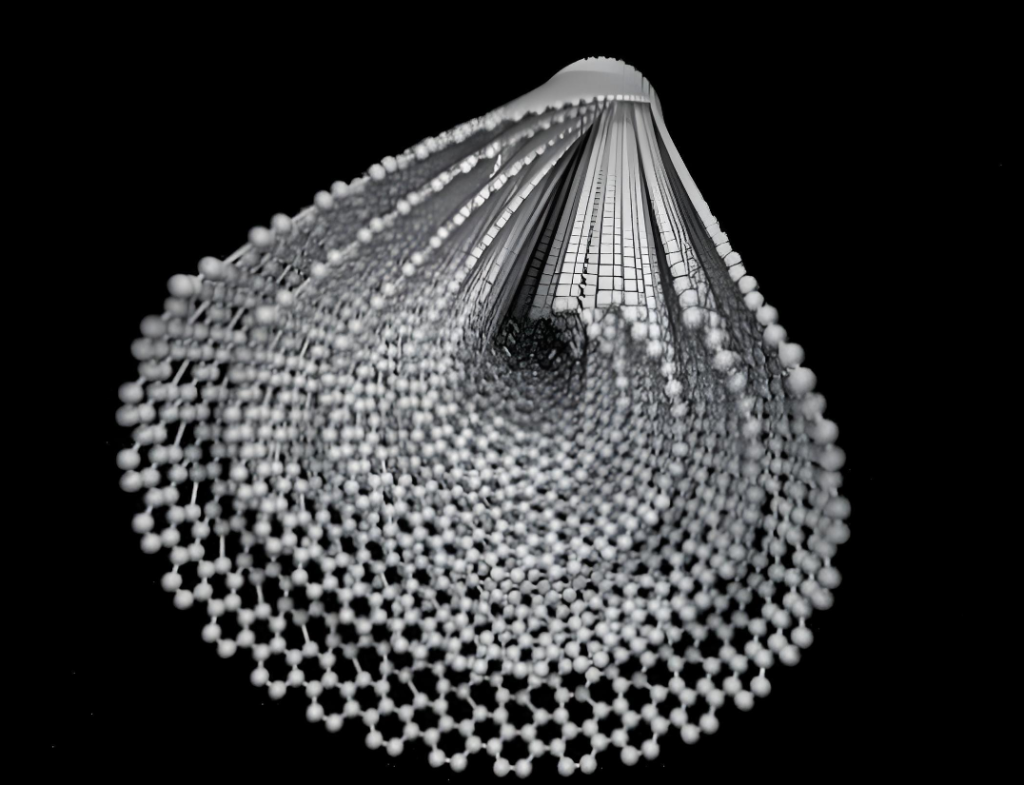

2. Why Graphene Works in Anticorrosive Coatings

Graphene’s unique properties make it an ideal additive for high-performance coatings:

-

Atomic-scale Barrier

-

Graphene sheets are impermeable to gases and liquids

-

Prevents oxygen, water, and corrosive ions from reaching the substrate

-

-

High Aspect Ratio

-

Thin yet wide graphene sheets increase tortuosity

-

Slows the diffusion path of corrosive agents, reducing the rate of degradation

-

-

Mechanical Reinforcement

-

Graphene strengthens polymer matrices

-

Enhances crack resistance and adhesion to substrates

-

-

Chemical Stability

-

Resistant to acids, alkalis, and solvents

-

Maintains barrier performance under harsh chemical exposure

-

Together, these properties extend coating life and reduce maintenance frequency.

3. Types of Graphene-Based Anticorrosive Systems

Graphene can be integrated into coatings in various ways:

-

Graphene-Polymer Composites

-

Graphene dispersed in epoxy, polyurethane, or acrylic resins

-

Offers mechanical reinforcement and barrier properties simultaneously

-

-

Functionalized Graphene

-

Surface-modified graphene improves compatibility with resin systems

-

Enhances dispersion, adhesion, and long-term stability

-

-

Graphene Hybrids

-

Combined with CNTs or traditional fillers

-

Balances conductivity (for cathodic protection) and barrier performance

-

Each system is tailored for specific application requirements, from marine coatings to industrial machinery.

4. Mechanism of Enhanced Corrosion Protection

Graphene enhances corrosion resistance through multiple mechanisms:

-

Physical barrier: Dense graphene sheets prevent corrosive species from penetrating

-

Increased tortuosity: Charged or neutral ions must navigate a longer, more complex path

-

Improved adhesion: Graphene strengthens the coating–substrate interface

-

Synergistic effects: In hybrid systems, CNTs form conductive pathways, mitigating localized electrochemical reactions

This combination makes graphene coatings particularly effective for long-term exposure to aggressive environments.

5. Performance Benefits vs. Conventional Coatings

| Feature | Traditional Coatings | Graphene-Enhanced Coatings |

|---|---|---|

| Barrier efficiency | Moderate | High, due to impermeable sheets |

| Crack resistance | Moderate | High, mechanical reinforcement |

| Chemical resistance | Moderate | Very high |

| Lifespan | 3–5 years typical | 2–3x longer under comparable conditions |

| Maintenance frequency | High | Lower, reduced downtime |

| Application flexibility | Standard | Compatible with multiple polymer matrices |

Graphene coatings allow engineers to achieve longer service intervals, reduced repair costs, and improved operational uptime.

6. Key Application Areas

-

Marine and Offshore Equipment

-

Protects hulls, pipelines, and platforms against saltwater corrosion

-

-

Automotive Industry

-

Prevents rust in high-exposure components, extending vehicle life

-

-

Industrial Machinery

-

Enhances wear and chemical resistance in chemical processing plants

-

-

Infrastructure & Construction

-

Extends lifespan of steel bridges, pipelines, and structural elements

-

In all cases, the goal is cost-efficient, long-term protection rather than short-term coverage.

7. Design Considerations for Graphene Coatings

To maximize performance:

-

Optimized Dispersion

-

Avoid agglomeration to ensure uniform barrier coverage

-

-

Controlled Loading

-

Sufficient graphene to form continuous barriers without compromising coating processability

-

-

Matrix Compatibility

-

Select polymer resins compatible with graphene chemistry

-

-

Environmental and Mechanical Stress Testing

-

Validate coating against UV, temperature cycling, and chemical exposure

-

Following these design principles ensures reproducible, long-lasting protection.

8. Challenges and Mitigation Strategies

-

Dispersion difficulty: Use functionalized graphene or hybrid systems

-

Cost considerations: Optimize loading and select high-efficiency graphene grades

-

Processing adaptation: Some coatings may require higher shear mixing or specialized equipment

Despite these challenges, the lifetime benefits and reduced maintenance often justify the incremental cost.

9. Future Outlook

Graphene anticorrosive coatings are increasingly:

-

Hybridized with CNTs for added mechanical and conductive benefits

-

Functionalized for enhanced adhesion and processability

-

Tailored for specific industries where long-term protection and minimal downtime are critical

As production scales and cost efficiencies improve, adoption will accelerate across industrial, automotive, and marine sectors.

Graphene enhances anticorrosive coatings by providing atomic-scale barriers, mechanical reinforcement, and chemical stability.

-

Lifespan increases 2–3x compared to traditional coatings

-

Maintenance frequency is reduced

-

Performance remains stable under harsh environmental conditions

For industries where durability and reliability matter, graphene is not just an additive—it is a strategic solution for long-term corrosion protection.