Graphene as a Game-Changer in Thermal Management Materials

Introduction: The Growing Need for Efficient Thermal Management

In today’s fast-evolving technological world, efficient thermal management has become a critical requirement in fields such as:

-

Consumer electronics (e.g., smartphones, laptops, wearables)

-

Electric vehicles (EVs)

-

High-power LEDs

-

Energy storage systems

-

Aerospace and military-grade electronics

As devices shrink and power densities rise, heat buildup threatens performance, lifespan, and safety. Traditional materials like aluminum, copper, and thermal greases are reaching their limits.

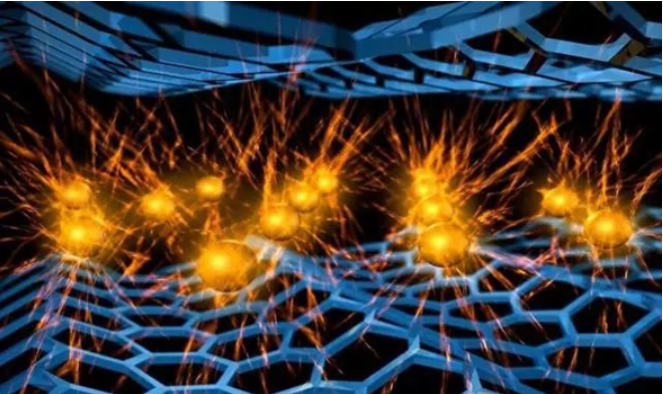

Enter graphene — the wonder material known for its extraordinary thermal conductivity and lightweight structure. Its ability to rapidly dissipate heat while remaining ultrathin and flexible is opening new avenues in heat management systems.

This article delves into how graphene can revolutionize the way we handle thermal challenges in advanced electronics and industrial systems.

🧊 Section 1: Understanding Graphene’s Thermal Superiority

Graphene’s in-plane thermal conductivity is measured at 2000–5000 W/m·K, far surpassing traditional metals like:

-

Copper (~400 W/m·K)

-

Aluminum (~235 W/m·K)

-

Silicon (~150 W/m·K)

Why is this important?

Graphene’s single-atom-thick carbon lattice allows phonons (quantized heat carriers) to travel with minimal scattering, enabling ultra-efficient heat flow.

What makes graphene unique is that it combines:

-

High conductivity

-

Mechanical flexibility

-

Chemical resistance

-

Lightweight (negligible mass)

These features are ideal for next-generation thermal interface materials (TIMs), coatings, films, and composites.

🧱 Section 2: Key Forms of Graphene Used in Thermal Management

Graphene is integrated into thermal systems through several forms:

✅ 1. Graphene Films

-

Large-area, free-standing or substrate-supported

-

Used in smartphones, processors, or batteries

-

Often CVD-grown or made via reduction of graphene oxide (rGO)

✅ 2. Graphene Powders/Flakes

-

Mixed into polymers or resins

-

Create thermally conductive pastes, epoxies, or adhesives

-

Offer scalable, low-cost options

✅ 3. Graphene-Enhanced Composites

-

Silicone, polyurethane, or epoxy matrices

-

Improve heat transfer in flexible or structural components

✅ 4. Graphene Aerogels and Foams

-

Lightweight, porous materials

-

Used for thermal insulation or EMI shielding with thermal dissipation

Each form serves different thermal application needs, balancing performance, cost, and manufacturability.

📐 Section 3: Application Fields and Case Examples

Graphene’s thermal capabilities are finding real-world applications in multiple industries.

🔋 1. Electric Vehicles (EVs) and Battery Packs

-

Graphene TIMs improve battery cooling efficiency

-

Prevent hotspots in Li-ion and solid-state battery packs

-

Enhance the lifespan and safety of EV modules

✅ Example: Chinese EV manufacturers are testing graphene-based thermal pads to replace traditional graphite sheets.

📱 2. Consumer Electronics

-

Graphene films are used in flagship smartphones for CPU heat dissipation

-

Graphene layers prevent overheating in compact wearable devices

✅ Example: Xiaomi, Huawei, and Samsung have integrated graphene cooling films in high-performance smartphones.

💡 3. High-Power LEDs

-

LEDs lose efficiency with rising temperature (thermal quenching)

-

Graphene composites help dissipate heat from the diode junction, improving brightness stability

🚀 4. Aerospace and Defense

-

Graphene composites can withstand harsh temperatures in avionics

-

Lightweight thermal interfaces reduce mass in satellites and drones

🧪 5. Industrial Thermal Pastes and Gap Fillers

-

Replacing silver-based pastes with graphene-enhanced materials

-

Less expensive, better long-term stability, and eco-friendlier

📊 Section 4: Performance Metrics in Graphene-Based Thermal Materials

| Property | Typical Value |

|---|---|

| In-plane thermal conductivity | 2000–5000 W/m·K |

| Through-plane thermal conductivity (film stacks) | 10–50 W/m·K |

| Composite (epoxy/PU) thermal conductivity | 1–10 W/m·K |

| Weight | <1 g/cm² (film) |

| Operating temperature range | -40°C to 250°C (depending on matrix) |

| Thickness | 1–100 µm (films), variable for pastes/composites |

These values vary based on the graphene quality, orientation, and dispersion in the host material.

🧪 Section 5: Graphene vs Traditional Materials

| Feature | Graphene | Copper | Thermal Paste |

|---|---|---|---|

| Conductivity | ✅ High (up to 5000 W/m·K) | ✅ High (~400 W/m·K) | ❌ Limited (~1–5 W/m·K) |

| Weight | ✅ Ultra-light | ❌ Heavy | ✅ Light |

| Flexibility | ✅ Excellent | ❌ Rigid | ✅ Flexible |

| Long-Term Stability | ✅ Stable | ✅ Stable | ❌ Degrades over time |

| Thickness | ✅ Nanometers–microns | ❌ Bulk | ✅ Thin, but messy |

Graphene offers a cleaner, lighter, and more scalable alternative for emerging compact designs.

🏭 Section 6: Manufacturing and Integration Techniques

Graphene materials can be processed and integrated using various techniques:

-

Hot Pressing or Calendering of films

-

Coating or Slot Die Casting of graphene slurries

-

Inkjet Printing of graphene-based thermal inks

-

Molding with graphene-powder composites into custom shapes

-

Lamination or Transfer onto flexible substrates

Integration can be tailored depending on whether the application is:

-

Rigid (e.g., CPU module)

-

Flexible (e.g., wearable or foldable device)

-

Structural (e.g., battery casing, drone skin)

⚠️ Section 7: Current Challenges and Industry Needs

While graphene shows strong potential, several hurdles remain:

-

Cost-efficiency: High-performance graphene films can be expensive

-

Dispersion challenges: In powders or inks, uniform dispersion is critical for consistent heat conduction

-

Interfacial resistance: Contact resistance between layers or substrates can reduce real-world performance

-

Mass production: Scalable and reliable production remains a bottleneck for premium applications

Still, emerging startups and research centers are solving these problems through better chemistry, hybrid fillers, and AI-driven material formulation.

🧩 Section 8: How GrapheneRich Supports Thermal Management Needs

At GrapheneRich NanoTech, we offer materials tailored for thermal applications:

🔸 Graphene Thermal Powders:

-

Particle size: ~16 µm

-

BET surface area: ~120–150 m²/g

-

Works with epoxy, silicone, PU

-

Low oxygen content for better conductivity

🔸 Reduced Graphene Oxide (RGO) Dispersions:

-

Aqueous and solvent-based options

-

For printable thermal inks or coatings

-

Custom concentrations (0.5–5 mg/mL)

🔸 Technical Support:

-

Composite formulation advice

-

Integration with heat pads, adhesive films

-

Custom test samples available upon request

📩 Request a free sample or datasheet: https://graphenerich.com/contact

🔮 Conclusion: The Future is Cool with Graphene

From smartphones to satellites, thermal management is the silent key to performance, safety, and durability. As we push the boundaries of electronics and energy systems, traditional cooling materials are being outclassed.

Graphene — with its exceptional thermal properties and adaptability — is emerging as a leading material in this space. Whether used in thin films, flexible pastes, or lightweight composites, graphene will power the next wave of thermal innovation.

If you’re developing high-power, compact, or wearable systems, it’s time to explore how graphene can help you stay cool under pressure.