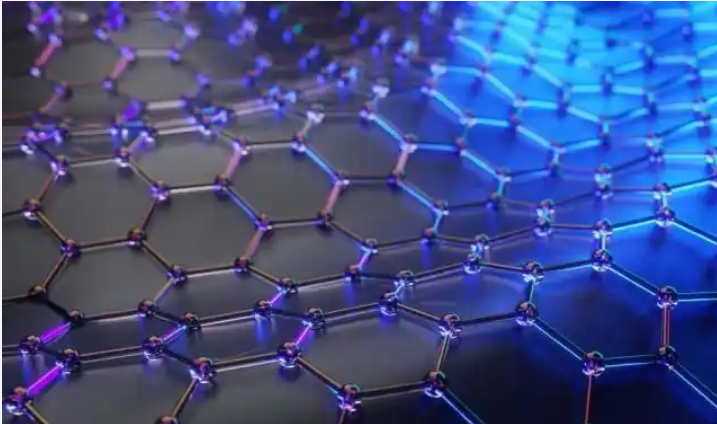

Graphene-Based Composite Materials for Smart Device Heat Dissipation

Why Go Beyond Pure Graphene?

While pure graphene is outstanding, it’s challenging to mass-produce at low cost. The solution? Graphene-based composites—hybrid materials combining graphene with polymers, ceramics, or resins for practical integration into electronics manufacturing.

Types of Graphene Composites

-

Graphene + Polymer: Flexible, printable cooling films for smartphones and tablets

-

Graphene + Epoxy Resin: Used in thermal interface pads for CPUs and batteries

-

Graphene + Ceramic: High-heat applications (e.g., power electronics, aerospace)

Use Case: Smartphone Thermal Film

A leading Asian smartphone manufacturer implemented graphene-polyimide hybrid films in its flagship model. Benefits included:

-

15% improvement in CPU cooling efficiency

-

20% longer sustained performance in gaming mode

-

Weight reduction compared to copper mesh layers

Advantages Over Traditional TIMs (Thermal Interface Materials)

| Property | Graphene Composite | Silicone-based TIM | Phase Change Material |

|---|---|---|---|

| Thermal Conductivity | High | Medium | Medium |

| Form Factor | Ultra-thin & flexible | Gel/Paste | Solid/Paste |

| Durability | Very High | Medium | Low (degrades over cycles) |

Cost and Scalability

Recent innovations in graphene ink printing and spray deposition make these composites increasingly viable for mass production. With global investment into graphene supply chains, cost barriers are quickly falling.

Looking Forward

The rise of flexible electronics, foldable displays, and wearables will accelerate demand for smart thermal solutions. Graphene composites strike the right balance between performance, flexibility, and manufacturability.

Conclusion

By integrating graphene into composite materials, manufacturers are unlocking new levels of heat dissipation performance. For anyone designing thermally-challenging devices—phones, EVs, wearables—graphene composites are no longer an option; they are a competitive necessity.