Graphene-Based Sensors for Hydrogen Leak Detection: A Critical Application in Hydrogen Energy

Hydrogen energy is gaining prominence as a clean and sustainable alternative to fossil fuels. However, the widespread use of hydrogen comes with significant challenges, particularly the detection and prevention of hydrogen leaks. Hydrogen is colorless, odorless, and highly flammable, posing serious safety risks if not monitored effectively. This is where graphene-based sensors come into play, offering unparalleled sensitivity, rapid response, and high reliability in hydrogen leak detection.

This article explores the role of graphene in hydrogen sensor applications, detailing its unique properties, working mechanisms, and practical implementations in ensuring safety across hydrogen energy systems.

Why Hydrogen Leak Detection Matters

- Safety Risks:

- Hydrogen’s low ignition energy and wide flammability range (4%–75% in air) make it a high-risk gas.

- Operational Efficiency:

- Undetected leaks can lead to inefficiencies and economic losses in hydrogen energy systems.

- Regulatory Compliance:

- Hydrogen energy applications must meet stringent safety standards, necessitating advanced leak detection technologies.

- Environmental Impact:

- While hydrogen itself is non-toxic, leaks can contribute to indirect environmental issues, such as affecting atmospheric chemistry.

Graphene’s Unique Advantages in Hydrogen Sensing

Graphene, a two-dimensional carbon material, possesses a combination of properties that make it an ideal candidate for hydrogen sensors:

- High Surface Area:

- A single layer of graphene provides a large surface area for gas adsorption, enhancing sensitivity.

- Excellent Electrical Conductivity:

- Changes in graphene’s conductivity upon gas adsorption enable precise detection of hydrogen molecules.

- Fast Electron Mobility:

- Graphene’s ultrafast electron mobility allows for rapid response and recovery times in sensing applications.

- Flexibility and Scalability:

- Graphene-based sensors can be fabricated on flexible substrates, making them adaptable to various industrial settings.

- Stability and Durability:

- Graphene is chemically and thermally stable, ensuring consistent performance in extreme conditions.

Working Mechanism of Graphene Hydrogen Sensors

Graphene-based hydrogen sensors primarily operate on the principle of chemiresistance or field-effect transistor (FET) configurations:

- Chemiresistive Sensors:

- Hydrogen molecules adsorb onto the graphene surface, altering its electrical resistance due to charge transfer.

- FET-Based Sensors:

- The interaction between hydrogen and graphene modulates the conductivity of the graphene channel in the transistor, producing a measurable signal.

- Enhanced Sensitivity with Catalysts:

- Functionalizing graphene with catalytic metals (e.g., palladium or platinum) improves its hydrogen adsorption capacity, enabling detection at lower concentrations.

Applications of Graphene-Based Hydrogen Sensors

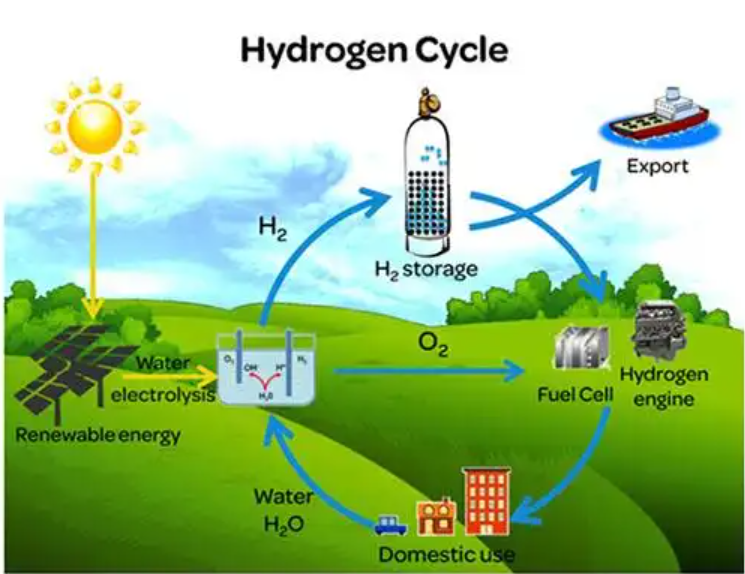

1. Hydrogen Storage Systems

- Use Case:

- Detecting leaks in high-pressure hydrogen storage tanks and pipelines.

- Example:

- Graphene-palladium sensors achieved detection limits as low as 10 ppm, ensuring real-time monitoring.

2. Hydrogen Fueling Stations

- Use Case:

- Continuous monitoring of hydrogen dispensing systems to prevent accidents.

- Example:

- Flexible graphene sensors integrated into fueling station infrastructure provided rapid leak detection under dynamic conditions.

3. Fuel Cell Applications

- Use Case:

- Detecting internal hydrogen leaks in proton-exchange membrane (PEM) fuel cells.

- Example:

- Graphene-coated microelectrodes ensured reliable leak detection without interfering with cell performance.

4. Aerospace and Automotive Industries

- Use Case:

- Monitoring hydrogen leaks in fuel tanks and delivery systems in hydrogen-powered vehicles and aircraft.

- Example:

- Graphene sensors embedded in vehicle bodies provided lightweight and efficient leak detection solutions.

Key Performance Metrics

- Detection Limit:

- Graphene sensors can detect hydrogen concentrations as low as 1 ppm.

- Response Time:

- Typical response times are in the range of milliseconds to seconds, critical for safety applications.

- Operating Temperature:

- Graphene sensors maintain performance over a wide temperature range (-100°C to 300°C).

- Selectivity:

- Functionalized graphene enhances selectivity for hydrogen, minimizing interference from other gases.

Recent Advancements in Graphene Hydrogen Sensors

- Graphene-Palladium Hybrids:

- Combining graphene with palladium nanoparticles improved hydrogen adsorption and sensor response time.

- Laser-Induced Graphene (LIG):

- LIG-based sensors offer a low-cost, scalable approach for fabricating high-performance hydrogen detectors.

- Flexible and Wearable Sensors:

- Graphene-based sensors on flexible substrates enable wearable hydrogen monitoring for industrial workers.

- Graphene Aerogels:

- Aerogel structures provide enhanced surface area and sensitivity, suitable for ultra-low concentration detection.

- Integration with IoT:

- Graphene sensors paired with IoT platforms allow real-time hydrogen monitoring and remote alert systems.

Challenges and Future Directions

- Cost of Production:

- Scaling up the production of high-quality graphene for commercial sensors remains a challenge.

- Catalyst Optimization:

- Identifying cost-effective alternatives to palladium and platinum for functionalization.

- Durability Under Harsh Conditions:

- Ensuring long-term stability of sensors in high-pressure and high-temperature environments.

- Integration with Devices:

- Developing compact and integrated sensor solutions for hydrogen-powered devices.

Conclusion

Graphene-based sensors are at the forefront of hydrogen leak detection technology, offering unmatched sensitivity, speed, and adaptability. By addressing the critical safety challenges in hydrogen energy systems, graphene sensors pave the way for a secure and sustainable hydrogen economy.

As advancements in graphene production and sensor design continue, these innovations will play a pivotal role in ensuring the safety and efficiency of hydrogen energy applications worldwide.