Graphene-Based Water Purification Membranes: Tackling Global Water Scarcity

Access to clean, safe drinking water is one of the most pressing challenges of the 21st century. The World Health Organization estimates that over 2 billion people live in areas experiencing water stress. Climate change, industrial pollution, and population growth are placing unprecedented strain on global water resources.

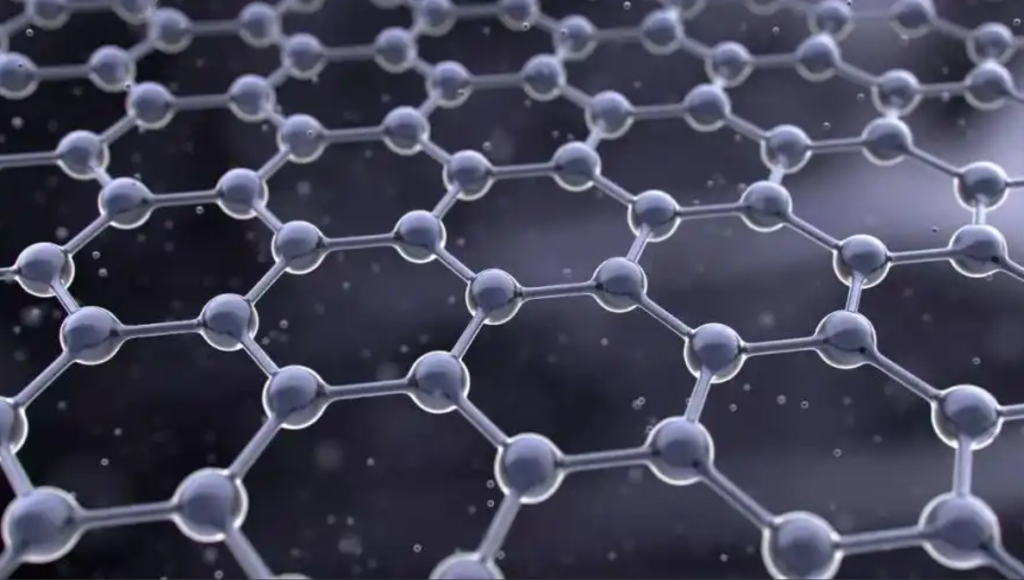

Graphene-based membranes have emerged as a promising solution for efficient, scalable, and cost-effective water purification. With their ultrathin structure, superior mechanical strength, and precise molecular sieving capability, graphene membranes can filter contaminants faster and more selectively than traditional filtration systems.

Why Graphene for Water Purification?

Graphene’s unique properties make it an exceptional material for filtration membranes:

-

Atomic Thickness: Enables faster water flow while maintaining selectivity.

-

High Mechanical Strength: Prevents damage under high pressure.

-

Chemical Resistance: Withstands harsh water conditions and cleaning processes.

-

Tunable Pore Size: Graphene oxide (GO) sheets can be engineered with nanoscale pores for targeted filtration.

Compared to reverse osmosis membranes, graphene membranes can increase water flux by up to 50% while using less energy.

Key Applications in Water Treatment

1. Desalination

-

Challenge: Converting seawater into drinking water is energy-intensive with traditional reverse osmosis (RO) membranes.

-

Graphene Advantage: Graphene membranes with nanopores smaller than 1 nanometer can block salt ions while allowing water molecules to pass through at high speed.

-

Outcome: Reduced energy consumption and lower operational costs for desalination plants.

2. Removal of Heavy Metals

-

Heavy metals like lead, arsenic, and mercury pose severe health risks.

-

Graphene oxide membranes can be functionalized to chemically bind heavy metal ions, removing them from contaminated water sources.

3. Industrial Wastewater Treatment

-

Textile, mining, and chemical industries produce wastewater containing dyes, solvents, and microplastics.

-

Graphene-based membranes offer high chemical resistance and selective filtration for industrial contaminants, enabling water recycling.

4. Point-of-Use Filtration

-

Compact graphene filters can be integrated into portable purifiers or household systems.

-

This application is critical in remote regions and during natural disasters where centralized water treatment is unavailable.

Research and Commercial Progress

-

MIT researchers developed graphene oxide membranes that desalinate seawater up to 3x faster than commercial RO membranes.

-

Lockheed Martin patented a graphene-based “Perforene” membrane with nanoscale pores for desalination and filtration.

-

Chinese startups are scaling GO membrane production for municipal water treatment facilities.

Challenges to Overcome

-

Scaling Up Production: Large-area, defect-free graphene membranes are difficult to produce consistently.

-

Durability: Membranes must resist fouling (clogging) over time.

-

Cost: Current fabrication methods are more expensive than conventional membranes.

The next decade could see:

-

Hybrid Membranes: Combining graphene with polymer supports for better durability and cost reduction.

-

Smart Filtration Systems: Integrating sensors into membranes for real-time water quality monitoring.

-

Off-Grid Solutions: Solar-powered graphene filtration units for remote communities.

Graphene membranes could revolutionize global water purification by providing faster, more energy-efficient, and highly selective filtration. As manufacturing technologies mature, these membranes could be deployed at scale, helping tackle one of humanity’s most urgent resource challenges.