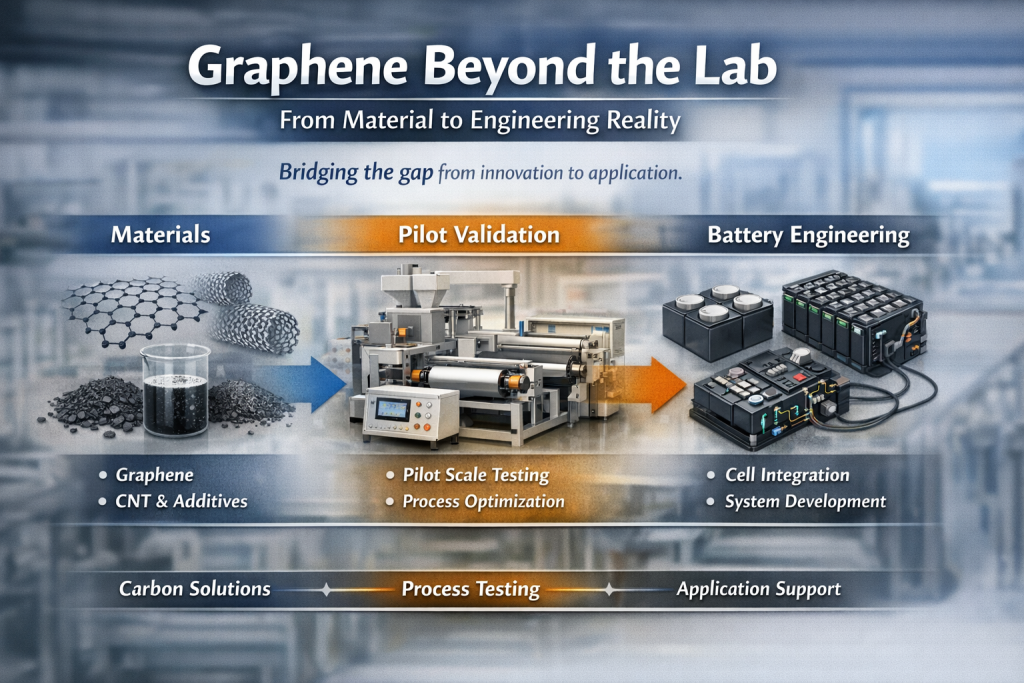

Graphene Beyond the Lab: From Material to Engineering Reality

Not just materials. A bridge between lab results, pilot validation, and battery engineering.

1. The gap no one talks about

Graphene has been in papers for more than a decade.

Most engineers already know what it can do:

-

improve conductivity

-

enhance thermal pathways

-

reinforce interfaces

-

extend cycle life (in the right system)

But in real projects, the question is rarely

“Does graphene work?”

The real question is:

Can it be integrated into a production system without breaking everything else?

Between lab-scale materials and real battery production, there is a quiet but critical gap:

-

slurry compatibility

-

dispersion stability

-

coating process windows

-

scale-up reproducibility

-

cost vs. performance tradeoffs

-

pilot-line validation

This is where many graphene discussions stop.

And where engineering reality begins.

2. From material supply to engineering connection

The industry doesn’t need another graphene brochure.

It needs connection points.

In most battery or energy projects, there are three layers:

Material layer

Graphene, CNT, conductive additives, coatings

Process layer

Dispersion → slurry → coating → drying → lamination

Engineering layer

Cells → modules → packs → thermal & safety systems

The challenge is not at any single layer.

It’s at the interfaces between them.

This is where we position ourselves:

Not just a material supplier.

A connection layer between material, pilot validation, and engineering application.

3. Why pilot-scale matters more than lab data

Lab results are controlled.

Production lines are not.

A graphene formulation that looks perfect in a beaker can fail when:

-

viscosity changes at 100 L scale

-

coating speed increases

-

solvent systems shift

-

binder systems vary

-

drying ovens behave differently

Pilot-scale validation answers practical questions:

-

Can this dispersion run on existing coating lines?

-

Does it require process modification?

-

Is the improvement measurable at cell level?

-

What is the cost-performance balance at scale?

Without this step, many “promising materials” never reach engineering use.

That’s why pilot capability is not just an extra resource —

it’s a decision-making tool.

4. Where graphene actually fits today

Graphene is rarely a standalone solution.

It works best as an enabling material in specific roles:

Thermal pathways

Heat spreading layers

Interface fillers

Coatings for localized hot spots

Conductive networks

Hybrid conductive systems with CNT

Low-loading performance tuning

High-rate support

Protection & interfaces

Anti-corrosion coatings

Barrier layers

Current collector modifications

Structural support (limited but real)

Composite reinforcement

Flexible conductive structures

In most successful projects, graphene is:

a system modifier, not a system replacement.

5. The importance of engineering translation

For graphene to move beyond the lab, three translations must happen:

Material → Process

Can it be dispersed, coated, dried, and scaled?

Process → Cell

Does it improve measurable performance?

Cell → System

Does it make sense at module or pack level?

Many failures happen because one of these translations is missing.

What the industry increasingly needs are teams that can move across all three layers — even if they don’t manufacture the final cells themselves.

6. A quiet role in the middle

There is a growing space in the industry for what could be called:

the engineering middle layer

Not cell manufacturers.

Not pure material vendors.

But a connector between the two.

This includes:

-

material selection guidance

-

dispersion & formulation support

-

pilot-scale validation

-

cross-team technical alignment

-

realistic performance expectations

When done well, this layer reduces risk for everyone:

-

material companies

-

battery developers

-

system integrators

-

investors

And most importantly:

it helps promising materials reach real applications faster.

7. What we focus on

Our work sits at the intersection of:

Carbon materials

Graphene

CNT

Hybrid conductive systems

Thermal & protective coatings

Pilot validation

Small-to-mid scale process testing

Formulation adaptation

Engineering feedback loops

Battery & energy applications

LFP / NCM systems

Sodium-ion exploration

Thermal management structures

Interface materials

We don’t approach graphene as a single product.

We approach it as part of an engineering system.

Sometimes the right answer is to use more graphene.

Sometimes less.

Sometimes none at all.

The goal is not to “sell graphene.”

The goal is to make systems work.

8. Building industry understanding over time

Industry trust doesn’t come from one announcement.

It comes from consistent, practical discussion.

By sharing:

-

application scenarios

-

pilot insights

-

integration challenges

-

realistic expectations

…a clearer picture forms over time.

After months of steady communication, people begin to understand:

who can actually help move materials into engineering reality.

No hard selling.

Just visible capability.

9. Looking forward

Graphene is already beyond the lab.

But it is not yet everywhere — and it shouldn’t be.

Its real impact will come from:

-

targeted integration

-

engineering validation

-

cost-aware deployment

-

collaborative development

The future of graphene is not in headlines.

It’s in quietly working systems.

And in the teams that help bridge

materials → pilot → engineering reality.