Graphene-Coated Fabrics – Smart Textiles with Conductive and Thermal Functions

As the demand for smart and functional textiles continues to rise, graphene-coated fabrics are becoming a breakthrough solution that bridges electronics, materials science, and wearable technology.

By combining the flexibility and comfort of traditional fabrics with the electrical, thermal, and mechanical properties of graphene, these advanced textiles open new opportunities in wearable electronics, thermal management, healthcare monitoring, and protective clothing.

This article explores how graphene coatings are made, the key performance benefits, and how these smart materials are shaping the future of flexible and wearable technologies.

1. Why Graphene for Smart Textiles

Smart textiles integrate functional materials into fabrics to enable sensing, heating, or energy management without compromising comfort.

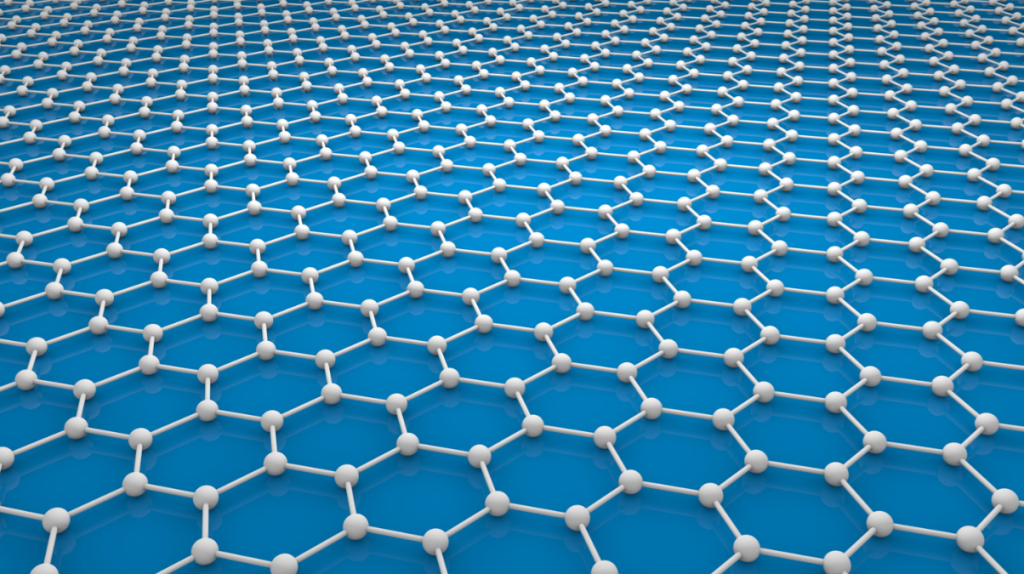

Graphene — a single atomic layer of carbon arranged in a honeycomb lattice — is uniquely suited for textile applications because it combines:

-

High electrical and thermal conductivity

-

Flexibility and mechanical strength

-

Lightweight and breathable structure

-

Chemical and environmental stability

Unlike metallic coatings that crack or oxidize, graphene adheres well to textile fibers and maintains performance under bending, washing, and stretching — a crucial advantage for wearable and outdoor products.

2. What Are Graphene-Coated Fabrics?

Graphene-coated fabrics are textiles (such as cotton, polyester, nylon, or nonwoven substrates) that have been surface-modified with a thin layer of graphene or graphene oxide (GO).

The coating forms a continuous or partially connected conductive network across the fabric surface, enabling:

-

Electrical conductivity for current or signal transfer

-

Thermal conductivity for heating and temperature control

-

Electromagnetic shielding (EMI) for electronic protection

-

Enhanced strength and abrasion resistance

Depending on the target application, the coating can be tuned to prioritize conductivity, flexibility, or durability.

3. Common Fabric Substrates and Their Compatibility

| Substrate Type | Properties | Graphene Coating Compatibility |

|---|---|---|

| Cotton | Natural, breathable, hydrophilic | Excellent adhesion for water-based GO coatings |

| Polyester (PET) | Synthetic, smooth, hydrophobic | Requires surface treatment for bonding |

| Nylon | Tough, flexible, chemical resistant | Good for durable coatings |

| Nonwoven fabrics | Porous, low-cost | Suitable for industrial filters or large-area heaters |

Proper surface activation — through plasma, corona, or chemical pre-treatment — ensures that graphene layers adhere uniformly and remain stable under mechanical stress.

4. Coating and Deposition Techniques

The choice of coating method depends on the desired performance, scalability, and cost. The most common techniques include:

4.1 Dip Coating

-

Fabric is immersed in a graphene oxide (GO) or graphene dispersion, then dried and reduced.

-

Advantages: Simple, scalable, compatible with roll-to-roll processing.

-

Used for: Conductive and heating fabrics.

4.2 Spray Coating

-

Fine graphene dispersion is sprayed onto the textile surface.

-

Advantages: Uniform coverage, low material waste, suitable for 3D fabrics.

-

Used for: Sensors and flexible heaters.

4.3 Screen Printing

-

Graphene pastes or inks are printed onto specific fabric areas.

-

Advantages: High pattern accuracy, ideal for circuits or logo-based heaters.

-

Used for: Wearable devices and decorative conductive designs.

4.4 Chemical Vapor Deposition (CVD)

-

Produces high-quality monolayer graphene films, later transferred to fabrics.

-

Advantages: Exceptional conductivity and uniformity.

-

Limitations: High cost, limited scalability.

-

Used for: Research and high-end electronics textiles.

4.5 In-Situ Reduction of GO

-

GO-coated fabrics are chemically or thermally reduced to conductive rGO layers.

-

Advantages: Tunable conductivity and cost efficiency.

-

Widely used in commercial graphene textile coatings.

5. Thermal and Electrical Mechanisms

5.1 Electrical Conductivity

The interconnected graphene flakes form percolation networks, allowing electrons to move freely through the coating.

Typical sheet resistance: 10–1,000 Ω/□, depending on coating thickness and reduction degree.

5.2 Thermal Conductivity

Graphene efficiently transfers heat along the plane of the fabric, distributing warmth evenly.

This property enables low-voltage heating fabrics for comfort and safety applications.

5.3 Stability and Durability

Graphene’s strong π–π bonding and chemical stability ensure the coating remains functional even after multiple washing and bending cycles.

6. Key Performance Parameters

| Property | Typical Value / Range | Comment |

|---|---|---|

| Sheet Resistance | 10–1,000 Ω/□ | Tunable by coating thickness |

| Surface Temperature Rise | +30–60°C @ 5–12 V | Suitable for wearable heating |

| Wash Durability | 10–50 cycles | Depends on binder and curing method |

| Bending Cycles | >10,000 | Maintains conductivity under strain |

| Weight Addition | <10% | Lightweight and breathable |

| EMI Shielding Effectiveness | 20–40 dB | Effective against electronic interference |

7. Functional Advantages of Graphene-Coated Fabrics

7.1 Conductive and Flexible

Unlike metal-coated fabrics, graphene coatings remain conductive under deformation — ideal for bendable or stretchable wearables.

7.2 Uniform and Safe Heating

Low-voltage operation (typically 5–12 V) provides stable and evenly distributed heating without hotspots.

This makes them suitable for garments, gloves, car seats, or healthcare wraps.

7.3 Breathable and Lightweight

The thin graphene layer adds negligible mass while maintaining air permeability and softness, key for comfort in long-term wear.

7.4 EMI and Antistatic Protection

Graphene networks dissipate static charges and shield electromagnetic radiation, useful in industrial or medical environments.

7.5 Enhanced Mechanical Strength

Graphene coatings improve tensile and abrasion resistance, extending fabric lifespan and durability.

8. Application Areas

8.1 Wearable Heaters

-

Used in heated jackets, gloves, and therapy belts.

-

Graphene coatings allow fast heat-up, even distribution, and safe low-voltage operation.

8.2 Health and Sports Monitoring

-

Integration of graphene sensors for detecting motion, temperature, or heart rate.

-

Washable and conformable for continuous contact with the skin.

8.3 Smart Workwear

-

Conductive networks embedded into uniforms for energy management or communication functions.

-

Also used for safety wear with embedded heating and sensing.

8.4 EMI Shielding and Antistatic Fabrics

-

Industrial applications in cleanrooms, electronics manufacturing, and protective wear.

-

Graphene provides stable performance even under moisture or temperature changes.

8.5 Energy-Harvesting Textiles

-

Future designs integrate graphene-coated fabrics with triboelectric or thermoelectric modules, converting body movement or heat into power.

9. Processing and Integration Considerations

While graphene-coated fabrics offer significant potential, their success depends on:

-

Uniform coating: Avoiding conductivity variations across large surfaces.

-

Adhesion and durability: Optimizing binder systems and curing conditions.

-

Scalability: Using roll-to-roll dip or spray coating for mass production.

-

Compatibility: Matching coating formulation to different fiber chemistries.

-

Environmental impact: Shifting toward water-based and low-VOC systems.

For commercial production, reduced graphene oxide (rGO) remains the most practical solution — balancing conductivity, cost, and processing simplicity.

10. Future Trends

10.1 Integration with Printed Electronics

Combining graphene-coated fabrics with graphene or CNT inks can enable fully printed circuits on flexible textiles.

10.2 Multi-Functional Fabrics

Next-generation fabrics will combine heating, sensing, and energy storage in a single platform — for example, self-powered health monitoring garments.

10.3 Scalable Roll-to-Roll Manufacturing

Continuous coating systems are making it feasible to produce hundreds of meters of conductive fabric per hour, suitable for industrial-scale applications.

10.4 Hybrid Materials

Incorporating graphene with silver nanowires or CNTs further enhances conductivity without losing flexibility.

10.5 Smart Design and Connectivity

Integration with Bluetooth, IoT sensors, and low-voltage controllers will transform graphene-coated fabrics into interactive and intelligent systems.

Graphene-coated fabrics represent a powerful convergence of materials science and wearable technology.

By leveraging graphene’s exceptional conductivity, heat management, and durability, these textiles enable practical, comfortable, and high-performance smart systems.

From personal heating garments and medical monitors to industrial EMI protection, graphene fabrics are reshaping how we think about the interface between electronics and the human body.

As coating formulations, adhesion techniques, and scalable processes continue to mature, graphene-coated textiles will play a central role in the next generation of flexible, intelligent, and sustainable wearable solutions.