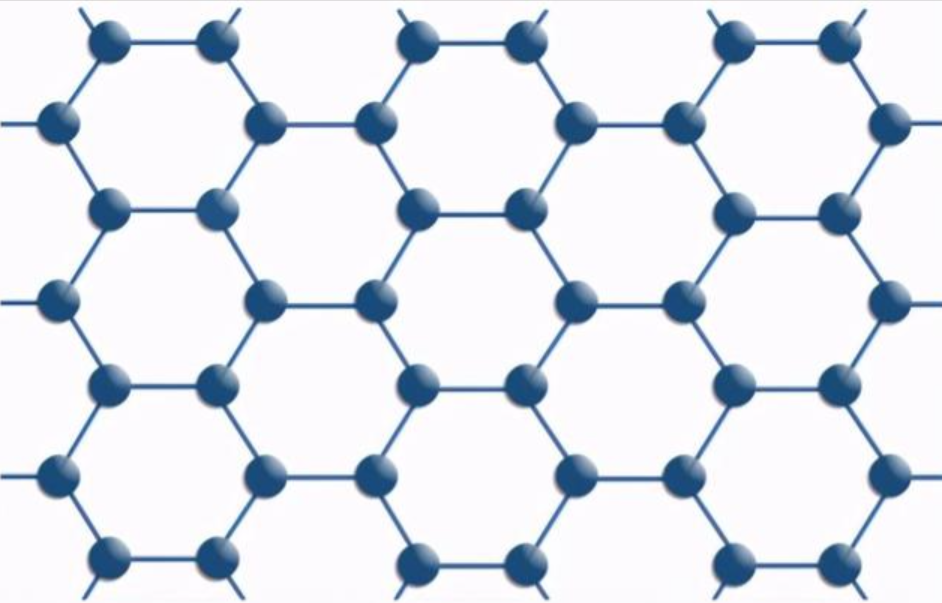

Graphene Coatings – Long-Lasting Protection Against Corrosion

Graphene-enhanced coatings offer superior corrosion protection by combining the strength and impermeability of graphene with the versatility of modern polymers. This unique synergy results in coatings that last significantly longer, require less maintenance, and withstand harsh environmental conditions.

Key Benefits of Graphene Anticorrosive Coatings

-

Superior Barrier Efficiency: Graphene’s atomic-scale structure prevents moisture, gases, and corrosive ions from penetrating.

-

Enhanced Mechanical Properties: Increases crack resistance and improves adhesion to various substrates, ensuring long-term stability.

-

High Chemical and Environmental Resistance: Excellent protection against acids, alkalis, salts, UV, and extreme temperatures.

-

Reduced Maintenance: Longer lifespan reduces the frequency of repairs and re-coating, ultimately saving on maintenance costs.

Applications by Industry

1. Marine & Offshore

-

Application: Hulls, pipelines, and platforms exposed to seawater

-

Benefit: Superior corrosion resistance in saltwater environments, increasing service life of critical marine assets

2. Automotive

-

Application: Underbody components, chassis, and fuel systems

-

Benefit: Long-term protection from rust and wear, improving vehicle durability and resale value

3. Industrial Machinery

-

Application: Chemical processing equipment, heat exchangers, and manufacturing plants

-

Benefit: Protects machinery against chemical corrosion, ensuring operational continuity and reducing downtime

4. Infrastructure & Construction

-

Application: Steel bridges, pipelines, and structural elements

-

Benefit: Provides long-lasting protection against environmental corrosion, reducing maintenance and enhancing the safety of infrastructure

Graphene Coatings vs. Traditional Coatings: A Comparative View

| Feature | Traditional Coatings | Graphene-Enhanced Coatings |

|---|---|---|

| Barrier Efficiency | Moderate | Very High, due to graphene’s impermeable structure |

| Crack Resistance | Moderate | Excellent, graphene enhances mechanical reinforcement |

| Chemical Resistance | Moderate | Excellent, resistant to acids, alkalis, and solvents |

| Lifespan | 3-5 years | 2-3x longer under similar conditions |

| Maintenance Frequency | High | Reduced, fewer maintenance intervals required |

Why Choose Graphene for Your Anticorrosive Needs?

Graphene’s unique combination of strength, durability, and versatility makes it the ideal solution for industries seeking cost-effective, long-term corrosion protection.

-

Longer Coating Life: Graphene coatings last significantly longer, reducing the need for frequent touch-ups or re-coating.

-

Increased Reliability: Reduce downtime and operational disruptions by using materials that resist environmental and chemical damage.

-

Sustainability: Fewer re-coating cycles result in reduced resource consumption and waste, contributing to your sustainability goals.

Product

Ready to extend the life of your assets?

Explore how graphene-enhanced coatings can improve corrosion resistance in your application.

Contact us today for a product demo, quote, or consultation.

Visual Map: Graphene Coatings in Action

Industries and Applications

(Here, an interactive map or diagram could show different applications in sectors like Marine, Automotive, Industrial Machinery, and Construction. Clicking on each sector could lead to more specific product data or case studies.)

-

Marine Industry: Hulls, propellers, offshore platforms

-

Automotive: Underbody protection, engine components

-

Industrial Machinery: Pipes, heat exchangers, chemical tanks

-

Infrastructure: Bridges, pipelines, steel structures