Graphene Conductive Film

Product Description

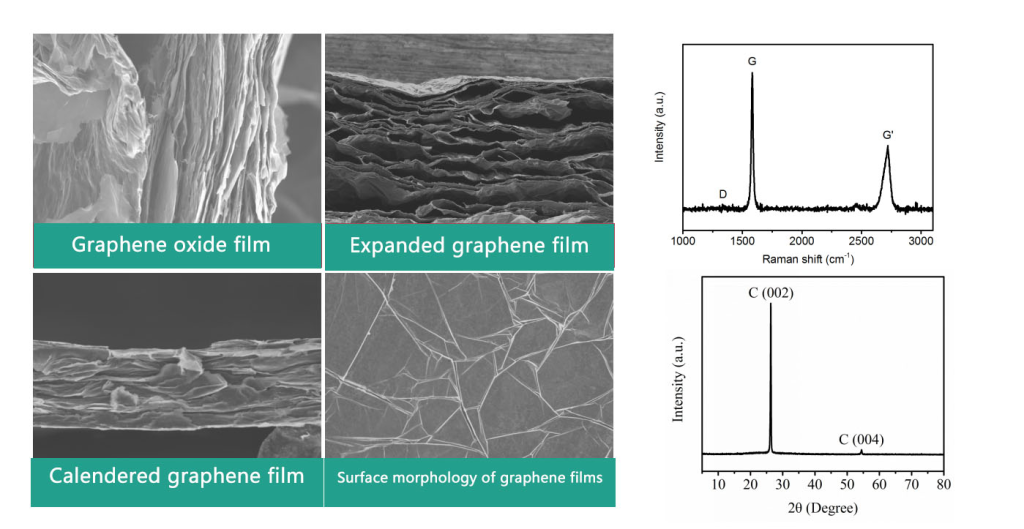

The graphene conductive film is made using graphene oxide as a precursor, followed by coating, pre-reduction, graphitization, and calendering processes. It offers excellent properties such as high thermal conductivity, high electrical conductivity, flexibility, lightweight, and fold resistance, providing an outstanding solution for RF microwave components in mobile smart devices.

Key Features

Microstructure:

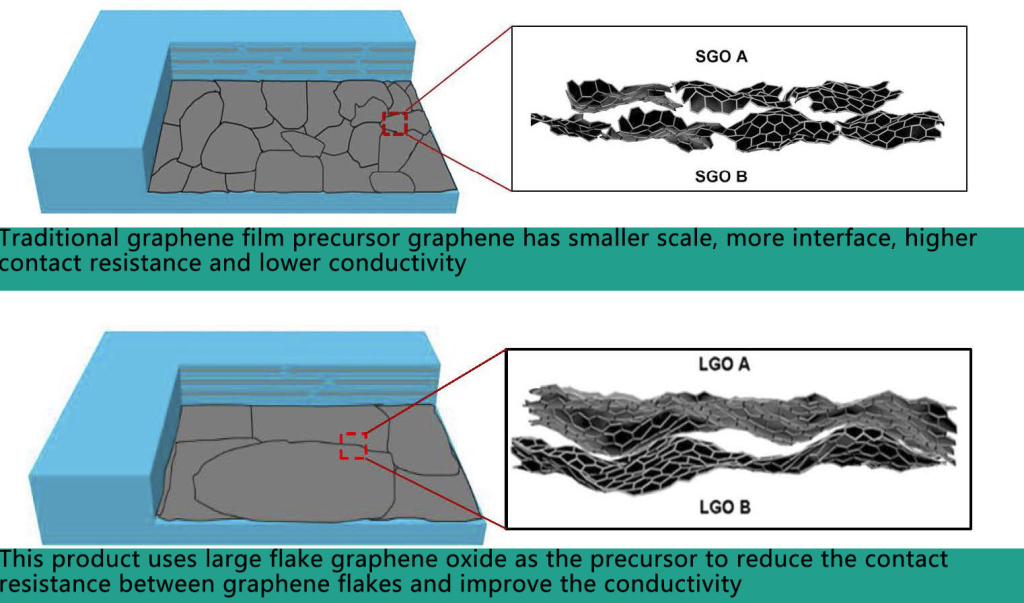

- Conductivity: The macro graphene conductive film consists of multiple large graphene flakes embedded and overlapping, offering high conductivity. The electrical conductivity decreases as thickness increases, with a tunable conductivity range of 1~5×10^6 S/m.

- Mechanical Properties: It can withstand up to 100,000 cycles of 180° bending (R1). The layered structure effectively absorbs bending stress, leading to minimal deformation and easy flexibility.

- Adjustable Thickness: The production process can be adjusted to create graphene conductive films of different thicknesses for various applications, with thicknesses ranging from 5 to 100μm.

- Corrosion Resistance: Made from carbon elements, the graphene conductive film is chemically inert, resistant to acids and bases, and has passed 4,320 hours of salt spray testing without corrosion.

- Lightweight: The graphene conductive film is only 1/5 to 1/4 the density of copper.

Mechanism of Action

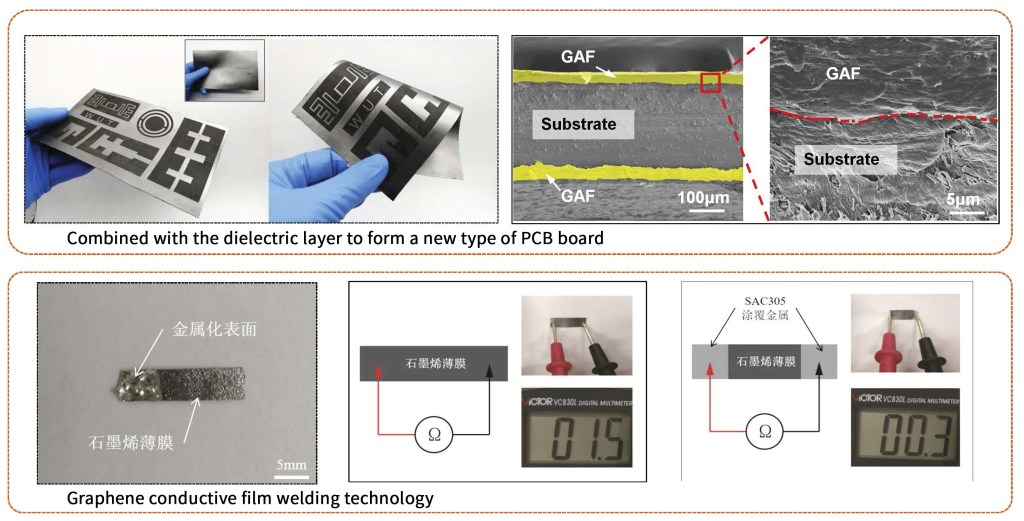

Graphene conductive film for PCB boards and welding technology.

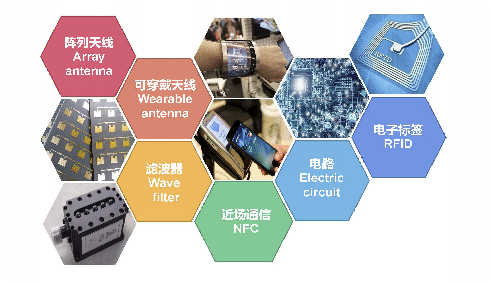

Applications

Graphene conductive films are ideal for use in RF microwave components in mobile smart devices due to their high conductivity, thermal properties, and flexibility.

Technical Parameters

| Parameter | HXCF-17 | HXCF-25 | Test Method |

|---|---|---|---|

| Thickness (μm) | 17±1 | 27±2 | ASTM D374 |

| Surface Resistance (mΩ) | <30 | <50 | GB/T 1551-2009 |

| Conductivity (S/m) | 1.2×10^6 | 1×10^6 | GB/T 1551-2009 |