Introduction

As energy storage systems become more powerful and compact, thermal management is a growing challenge. Overheating in lithium-ion and solid-state batteries can lead to performance loss, shortened lifespan, or in severe cases—thermal runaway and fires. Enter graphene, with its unmatched thermal conductivity and mechanical flexibility. This article explores how graphene-based materials are enhancing battery safety and performance through superior heat control.

1. The Thermal Challenge in Batteries

During high-rate charging/discharging, batteries generate heat in:

-

Electrodes (due to resistance and electrochemical reactions)

-

Separators and electrolytes

-

Battery Management Systems (BMS)

If not dissipated quickly:

-

Internal temperature rises

-

Electrolyte degradation accelerates

-

Risk of runaway reaction increases

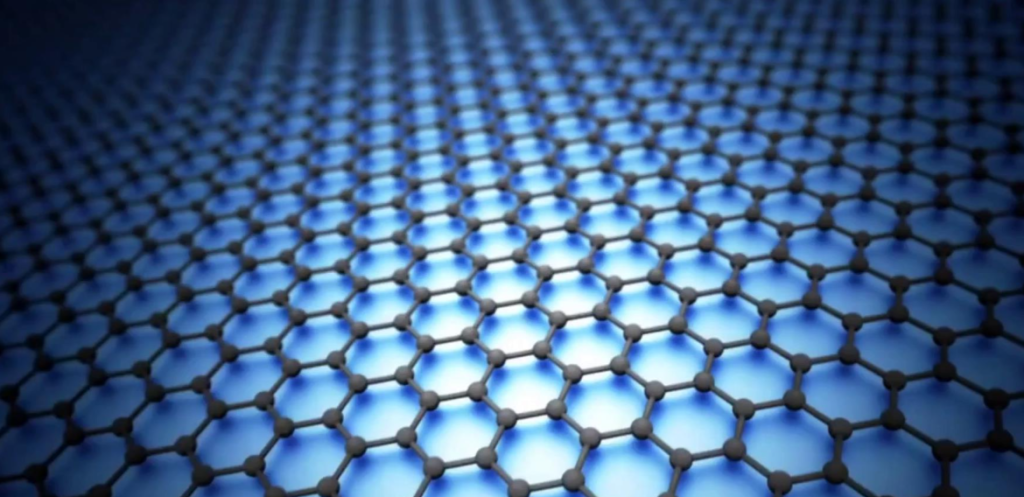

2. Why Graphene Is a Thermal Management Breakthrough

-

Thermal Conductivity: 3000–5000 W/m·K in pristine sheets

-

Flexibility: Adapts to curved or compact battery geometries

-

Lightweight: Maintains energy density while cooling

-

Multifunctionality: Can serve as both heat spreader and conductive layer

3. Graphene-Based Cooling Solutions

a. Graphene Heat Spreaders

Thin films or foils of graphene transfer heat away from battery cores to external surfaces, improving passive cooling in:

-

EV battery packs

-

Consumer electronics

-

Aerospace-grade storage modules

b. Graphene-Enhanced Thermal Interface Materials (TIMs)

These include:

-

Graphene-epoxy pastes

-

Graphene-gel pads

-

Graphene foams or aerogels

They fill microscopic gaps between heat sources and sinks, ensuring efficient thermal contact.

c. Graphene-Coated Separators

Separators are coated with graphene to:

-

Improve thermal conductivity

-

Prevent shrinkage under heat

-

Maintain ionic flow under high-stress cycles

4. Case Studies and Research

-

Samsung: Tested graphene layers in fast-charging smartphone batteries

-

Panasonic: Investigating graphene TIMs for EV batteries

-

University of Texas at Austin: Developed graphene-polymer hybrid films reducing peak battery temperature by >20°C

-

Chinese battery startups: Using graphene aerogels in pouch cell cooling systems

5. Applications Beyond Lithium-Ion

Graphene thermal solutions are applicable in:

-

Solid-State Batteries: Where thermal runaway risks remain

-

Li-Sulfur and Na-Ion batteries: Managing temperature spikes during cathode reactions

-

Hybrid supercapacitors: Allowing high-rate discharges without overheating

6. Manufacturing and Integration

a. CVD Graphene Films

Used in heat spreaders for their precision and stability

b. Reduced Graphene Oxide (rGO)

Used in TIMs and coatings for affordability and ease of dispersion

c. 3D Graphene Foams

Created by freeze-drying or templating methods for shock absorption and thermal buffering

7. Key Advantages Over Traditional Materials

| Property | Graphene | Copper/Aluminum |

|---|---|---|

| Thermal Conductivity | 3000–5000 W/m·K | ~400 W/m·K |

| Weight | Ultra-light | Heavy |

| Corrosion Resistance | High | Lower (especially Al) |

| Flexibility | Excellent | Poor |

Conclusion

Graphene is emerging as a powerful material for battery thermal management, delivering safer, faster, and longer-lasting energy systems. As more manufacturers integrate graphene-based heat spreaders, coatings, and TIMs, we move closer to a world where battery safety and performance go hand-in-hand—unlocking the true potential of electric mobility, portable electronics, and grid-scale energy storage.