Graphene for EMI Shielding: Protecting Electronics in a Wireless World

In today’s hyperconnected world, electronic devices are everywhere—from smartphones and laptops to advanced military systems and electric vehicles. As electronics become more compact and powerful, electromagnetic interference (EMI) becomes an increasingly critical issue. Traditional shielding materials like metals are heavy, rigid, and often inefficient at high frequencies. Enter graphene—a lightweight, conductive, and flexible material poised to revolutionize EMI shielding across industries.

Why EMI Shielding Matters

Electromagnetic interference can disrupt device performance, corrupt data, or even cause system failure. Sources of EMI include nearby circuits, RF communication systems, and power fluctuations. Effective shielding must:

-

Absorb or reflect electromagnetic waves

-

Maintain conductivity across large surface areas

-

Be lightweight and adaptable for modern electronics

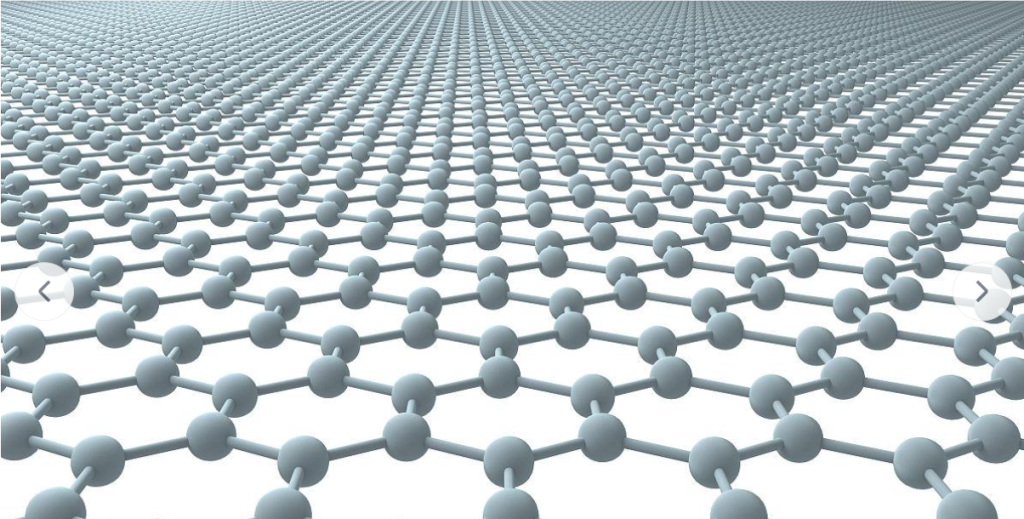

Graphene’s EMI Shielding Properties

Graphene exhibits unique traits that make it ideal for EMI shielding:

-

High electrical conductivity

-

Two-dimensional structure for maximum surface interaction

-

Mechanical strength and flexibility

-

Thermal stability

These properties allow graphene to outperform conventional metal-based shields in thin, lightweight layers—especially at microwave and higher frequencies.

Applications Across Industries

1. Consumer Electronics

Graphene coatings or films can be integrated into smartphone casings, tablets, and laptops to protect circuits from EMI without increasing weight or bulk.

2. Electric Vehicles (EVs)

EVs contain multiple electrical subsystems, including batteries, sensors, and controllers. Graphene composites offer EMI protection while reducing overall vehicle weight—critical for range and performance.

3. Medical Devices

Wearables and implantable electronics must be EMI-safe while remaining flexible. Graphene’s biocompatibility and shielding abilities make it a perfect fit.

4. Telecommunications

With the rise of 5G and mmWave frequencies, shielding becomes even more challenging. Graphene-based materials offer performance at high frequencies where metals become less effective.

Current Challenges

Despite the promise, mass production and uniform dispersion of graphene in polymer composites remain technical hurdles. Ongoing R&D focuses on scalable, cost-effective manufacturing methods.

Future Outlook

As the Internet of Things (IoT) expands and wearable electronics continue to shrink, graphene’s role in shielding sensitive devices will become increasingly central. Emerging research is also exploring multi-functional composites—materials that offer EMI shielding along with thermal management, mechanical reinforcement, and even sensing capabilities.

Graphene offers a transformative solution for EMI shielding challenges in modern electronic systems. Its conductivity, flexibility, and light weight provide engineers with a material that meets both technical and design demands. As production technologies improve, we can expect graphene EMI shielding to move from the lab to mainstream products.