Graphene for Flexible Energy Storage: Powering the Wearable Future

As wearable devices, electronic skin (e-skin), and IoT-integrated textiles evolve, energy storage systems must also become stretchable, foldable, and lightweight. Traditional lithium-ion batteries and capacitors are rigid, bulky, and prone to mechanical failure under stress. Graphene, with its exceptional electrical conductivity, high surface area, and flexibility, has emerged as the cornerstone of next-generation flexible energy storage.

🔹 1. The Need for Flexible Energy Storage

Applications demanding mechanical deformability:

-

Smartwatches, AR glasses, flexible phones

-

Health-monitoring patches, e-skin

-

Smart fabrics, motion-powered sensors

Challenges of traditional storage:

-

Heavy metal electrodes

-

Electrolyte leakage

-

Limited cycle life when bent or folded

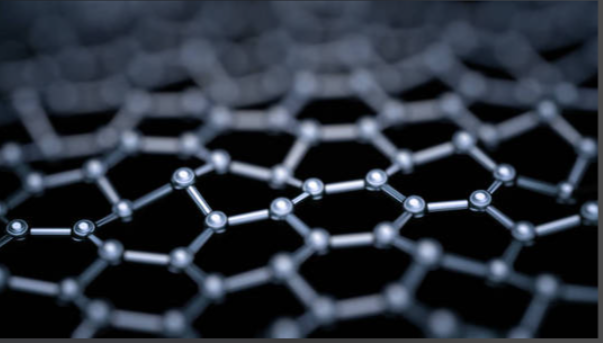

🔹 2. Why Graphene Is Ideal

Graphene provides:

-

Ultrathin structure (~1 atom thick)

-

Excellent conductivity (~10⁶ S/m)

-

Large surface area (>2600 m²/g)

-

Mechanical strength + flexibility

It supports faster ion transport, greater structural integrity, and stable electrochemical cycling.

🔹 3. Flexible Graphene-Based Supercapacitors

-

Electrode material: Pure graphene sheets, reduced graphene oxide (rGO), graphene foams

-

Performance:

-

Energy density: 10–30 Wh/kg

-

Power density: >10 kW/kg

-

Cycle life: >100,000 cycles

-

-

Substrates: PET, PDMS, textiles, paper

Used for:

-

Stretchable displays

-

Motion-charged wearables

-

Intermittent renewable energy buffering

🔹 4. Graphene in Flexible Batteries

a. Flexible Lithium-Ion Batteries (LIBs)

-

Graphene used as anode/cathode coating

-

Improves cycling stability and conductivity

-

Replaces brittle current collectors (e.g., Cu, Al)

b. Graphene–Zn Batteries

-

Safer than LIBs (aqueous electrolytes)

-

Used in flexible medical wearables

c. Solid-State Graphene Batteries

-

Ultra-thin form factors

-

Graphene + solid electrolyte → safer, bendable design

🔹 5. Real-World Developments

-

Samsung: Flexible graphene battery for foldable phones

-

UCLA: Laser-scribed graphene supercapacitors on plastic

-

Huawei & Xiaomi: R&D into graphene–polymer hybrid batteries

-

Chinese start-ups: Graphene supercaps for smart clothing

🔹 6. Manufacturing Trends

-

Inkjet/roll-to-roll printing of graphene inks

-

Spray coating and 3D printing on curved substrates

-

Low-cost, scalable methods needed for commercialization

🔹 Challenges and Outlook

Challenges:

-

Ensuring long-term stability under flex cycles

-

Improving capacitance without compromising flexibility

-

Eco-friendly, low-temperature manufacturing routes

Future trends:

-

All-graphene flexible power packs

-

Graphene + textile hybrid energy storage

-

Integration into stretchable solar + storage units

As the world moves toward integrated, wearable electronics, flexible energy storage will become critical infrastructure. Graphene stands out as a revolutionary material enabling high-performance, thin, and stretchable batteries and supercapacitors, helping realize the vision of seamless, smart, and sustainable electronics.