Graphene for Ocean Wave Energy Harvesting: Powering a Sustainable Blue Future

The ocean is one of the world’s largest untapped sources of renewable energy. With more than 70% of the Earth’s surface covered by water, the movement of tides and waves holds enormous potential for clean and sustainable electricity generation. Despite decades of research, however, wave energy harvesting systems have struggled to achieve widespread adoption due to challenges in efficiency, durability, and cost-effectiveness.

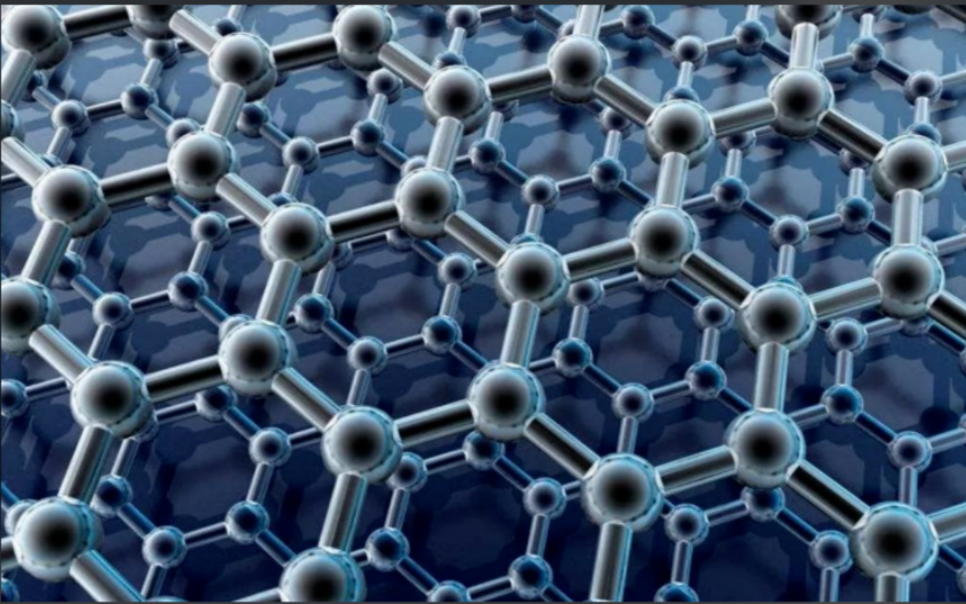

Enter graphene, a two-dimensional nanomaterial composed of a single layer of carbon atoms arranged in a honeycomb lattice. Graphene has gained attention across numerous industries thanks to its extraordinary conductivity, mechanical strength, chemical stability, and flexibility. When applied to ocean wave energy harvesting technologies, graphene offers transformative advantages, improving efficiency, durability, and scalability for the next generation of marine energy systems.

Why Ocean Wave Energy Matters

Before exploring graphene’s role, it’s worth understanding the significance of wave energy:

-

Abundant Resource: Waves can produce an estimated 2 terawatts (TW) of power globally, enough to meet a large fraction of human energy demand.

-

Predictability: Unlike solar and wind, wave patterns can be forecast with greater accuracy.

-

Consistency: Wave energy remains available even at night or during low-wind conditions.

-

Geographic Advantage: Coastal regions, where energy demand is high, are ideal for deployment.

Despite these advantages, existing wave energy converters (WECs) face difficulties including corrosion, material fatigue, energy losses, and high maintenance costs. This is where graphene steps in as a game-changer.

Why Graphene for Wave Energy Harvesting?

Graphene’s properties make it uniquely suited to harsh marine environments:

-

Superior Conductivity → Enhances efficiency in converting mechanical motion into electricity.

-

Corrosion Resistance → Protects devices from saltwater degradation.

-

Mechanical Strength → Withstands the intense pressures and stresses of ocean waves.

-

Lightweight & Flexible → Reduces structural weight while allowing adaptable device design.

-

Hydrophobic Behavior → Repels water, minimizing fouling and improving long-term durability.

-

Nanostructuring Potential → Can be engineered into coatings, composites, and electrodes for energy devices.

Mechanisms of Graphene Integration in Wave Energy Systems

1. Graphene-Coated Electrodes

-

Enhance electrical conductivity in energy conversion components.

-

Provide anti-corrosion protection against seawater.

2. Graphene Nanocomposites for Structural Materials

-

Graphene-reinforced polymers or metals improve strength-to-weight ratios.

-

Extend the lifetime of floating or submerged structures.

3. Graphene-Based Supercapacitors

-

Store harvested wave energy quickly and efficiently.

-

Enable rapid charge–discharge cycles, essential for fluctuating wave power.

4. Graphene in Triboelectric Nanogenerators (TENGs)

-

TENGs convert mechanical wave motion into electricity through surface charge transfer.

-

Graphene improves sensitivity, charge density, and stability, significantly boosting efficiency.

5. Anti-Fouling and Protective Coatings

-

Graphene-based coatings resist marine biofouling (barnacles, algae) and chemical erosion.

-

Reduce maintenance costs and extend service life.

Applications of Graphene in Ocean Wave Energy Harvesting

1. Offshore Energy Platforms

Graphene-enhanced materials can reinforce floating buoys and energy converters, increasing reliability in storm-prone waters.

2. Marine Sensors and IoT Devices

Small-scale graphene-based TENGs and supercapacitors can power autonomous marine sensors, essential for ocean monitoring, navigation, and defense applications.

3. Hybrid Renewable Energy Systems

Combining wave, solar, and wind with graphene-based storage solutions creates reliable offshore power stations.

4. Coastal Power Supply

Graphene-based WECs can deliver clean electricity directly to coastal communities, reducing reliance on fossil fuels.

5. Naval and Defense Applications

The navy can deploy graphene-enhanced WECs for stealthy, maintenance-free power supplies for underwater drones and surveillance systems.

Case Studies and Research Highlights

-

Zhejiang University (China): Developed a graphene-based TENG that efficiently harvested energy from water waves, showing significantly improved charge density.

-

Korea Advanced Institute of Science and Technology (KAIST): Created graphene-coated electrodes for wave energy devices with superior corrosion resistance.

-

University of Manchester: Investigated graphene composites for marine structural applications, demonstrating enhanced durability in saltwater.

-

Startups in Europe: Exploring graphene in hybrid wave–solar energy harvesting buoys, highlighting commercial interest in the technology.

Advantages of Graphene in Marine Energy Systems

-

Higher Efficiency → Improved conversion rates from wave motion to electricity.

-

Extended Lifespan → Resistance to corrosion, fouling, and fatigue.

-

Lower Maintenance Costs → Graphene coatings reduce the need for frequent servicing.

-

Lightweight Design → Enables more compact and deployable systems.

-

Energy Storage Integration → Graphene supercapacitors smooth out variable wave energy supply.

-

Eco-Friendly Materials → Reduces reliance on toxic or rare-earth elements.

Market Potential

The global wave energy market is expected to surpass USD 17 billion by 2032, with growing investment in renewable offshore solutions.

Simultaneously, the graphene market is forecast to reach USD 3–4 billion by 2032, with energy applications representing a significant growth driver.

Combining these two markets, graphene-based wave energy technologies stand at the intersection of two high-growth industries, offering:

-

Grid-scale energy solutions for coastal cities.

-

Decentralized renewable power for islands and remote locations.

-

Portable marine power systems for naval and industrial applications.

Challenges and Considerations

-

Cost of High-Quality Graphene – Commercial-scale production remains expensive.

-

Scalability of Manufacturing – Large-area graphene coatings and composites need industrial-level fabrication.

-

Durability Testing – Long-term marine performance must be validated.

-

Regulatory Barriers – Ocean deployment requires strict environmental approvals.

Future Outlook

The next decade will see increasing adoption of graphene in marine energy harvesting systems. Key developments may include:

-

Commercial Graphene-TENGs deployed on buoys for small-scale power generation.

-

Hybrid Marine Energy Farms using graphene-enhanced devices for wave, solar, and wind integration.

-

Self-Powered Marine Sensors for climate monitoring and oceanographic studies.

-

Ultra-Durable Offshore Platforms with graphene composites replacing traditional metals.

-

Cost-Effective Graphene Manufacturing that makes large-scale deployment feasible.

Graphene’s role in ocean energy harvesting is not just about efficiency—it’s about enabling a sustainable blue economy where renewable power and marine ecosystems coexist.

The ocean holds the promise of becoming a vast renewable energy reservoir, but harnessing its power requires materials that can endure corrosion, pressure, and environmental challenges. Graphene, with its unmatched strength, conductivity, and stability, is emerging as a transformative material for wave energy converters, marine coatings, and supercapacitors.

By enabling efficient, durable, and scalable wave energy harvesting systems, graphene is paving the way toward a cleaner, more sustainable energy future. From coastal communities to offshore industries, the fusion of graphene and wave energy represents a powerful step forward in the global renewable energy transition.