Graphene for Printed and Flexible Electronics: Enabling the Future of Lightweight Devices

The global electronics industry is undergoing a transformation driven by flexibility, portability, and sustainability. From wearable health monitors and rollable displays to RFID tags and lightweight sensors, printed and flexible electronics are paving the way for a new generation of devices.

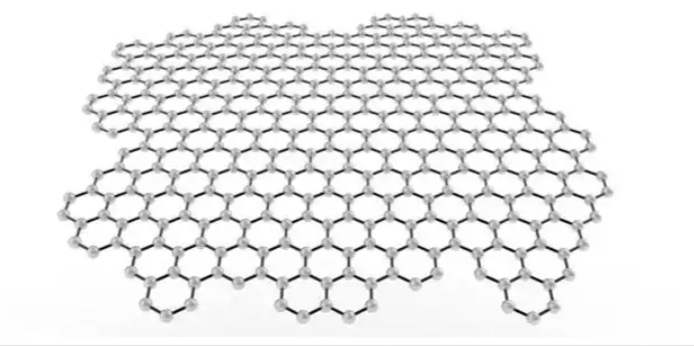

However, these devices demand materials that combine conductivity, flexibility, and cost-effectiveness — a combination that traditional metals and semiconductors often cannot provide. Graphene, with its atomic thinness, mechanical strength, and high electrical conductivity, has emerged as a leading candidate to solve this challenge.

This article explores how graphene is powering printed and flexible electronics, its benefits compared to traditional materials, industrial progress, and opportunities for exporters and integrators.

1. Why Graphene Fits Flexible and Printed Electronics

Graphene offers a unique set of properties that make it ideal for this industry:

-

High Conductivity

-

Graphene conducts electricity better than copper, ensuring efficient signal transfer in printed circuits.

-

-

Flexibility and Transparency

-

It can be bent, stretched, and folded without breaking, making it perfect for wearable and rollable devices.

-

-

Mechanical Strength

-

Despite being one atom thick, graphene is stronger than steel, giving devices structural reliability.

-

-

Lightweight Nature

-

Reduces the overall device weight — critical for wearable electronics.

-

-

Compatibility with Printing Processes

-

Graphene inks and pastes can be used in screen printing, inkjet printing, or roll-to-roll manufacturing, enabling scalable production.

-

2. Key Applications of Graphene in Printed and Flexible Electronics

a. Wearable Devices

-

Flexible heart rate monitors, glucose sensors, and smart patches use graphene electrodes for biocompatibility and accuracy.

-

Graphene’s breathability and flexibility improve user comfort compared to metallic foils.

b. Flexible Displays and Touch Panels

-

Graphene films replace indium tin oxide (ITO) as transparent conductive electrodes.

-

Unlike brittle ITO, graphene films withstand repeated bending in foldable smartphones and tablets.

c. Smart Packaging and RFID Tags

-

Graphene-based printed circuits enable low-cost, lightweight RFID tags for supply chain tracking.

-

Smart food packaging can include graphene sensors to monitor freshness or temperature.

d. Energy Devices (Printed Batteries and Supercapacitors)

-

Graphene inks enable printed supercapacitors and thin-film batteries.

-

Useful for powering small electronics, medical patches, and IoT devices.

e. Flexible Antennas and Communication Circuits

-

Graphene enables miniaturized antennas for IoT and 5G applications.

-

Combines conductivity with mechanical resilience for wearable communication devices.

3. Industrial Progress and Case Studies

-

Samsung and LG

-

Actively researching graphene electrodes for foldable smartphones.

-

-

Graphenea (Spain)

-

Supplies graphene inks for printed electronics applications.

-

-

Vorbeck Materials (USA)

-

Commercialized graphene inks for RFID tags and printed batteries.

-

-

Flexible Hybrid Electronics (FHE) Programs

-

EU and US government projects funding graphene-based printed circuits for defense and healthcare.

-

These examples highlight the commercial readiness of graphene inks and coatings in large-scale production.

4. Benefits Over Traditional Materials

-

Graphene vs. ITO (Indium Tin Oxide)

-

Graphene is cheaper, flexible, and more abundant compared to brittle, expensive ITO.

-

-

Graphene vs. Silver Nanoparticles

-

Silver inks are conductive but costly and prone to oxidation. Graphene offers stability and scalability.

-

-

Graphene vs. Copper

-

Copper suffers from corrosion and weight issues; graphene provides lightweight and durable alternatives.

-

5. Market Opportunities for Exporters and Integrators

For small and mid-sized exporters, graphene in printed and flexible electronics opens up new trade pathways:

-

Printed Electronics Manufacturers

-

Suppliers of graphene inks, coatings, and films can integrate into roll-to-roll production lines.

-

-

Medical Device Companies

-

Exporting graphene-based wearable sensors for healthcare applications.

-

-

IoT and Smart Packaging

-

Providing lightweight graphene RFID tags and sensors for logistics companies.

-

-

Consumer Electronics OEMs

-

Supplying conductive graphene films for smartphones, tablets, and wearables.

-

Given the global demand for IoT and wearable devices, this field is becoming one of the fastest-growing markets for graphene exporters.

6. Challenges and Future Outlook

-

Ink Formulation and Printing Precision

-

Achieving uniform graphene dispersion in inks is still complex.

-

-

Scalability and Cost

-

While progress has been made, high-quality graphene inks must become more affordable.

-

-

Standardization

-

Industry standards for printed electronics are still under development.

-

Nevertheless, as roll-to-roll printing technology advances, graphene is expected to replace ITO and silver inks in many consumer and industrial applications.

Graphene’s conductivity, flexibility, and transparency make it the ultimate enabler for printed and flexible electronics. From foldable displays to wearable medical devices, graphene is unlocking lightweight, durable, and scalable solutions for next-generation electronics.

For exporters and system integrators, this sector presents an exciting growth frontier — one where graphene materials can add significant value to industries ranging from consumer electronics to logistics and healthcare.