Graphene Heat Dissipation Films: Invisible Tech Behind Bright LEDs

In today’s high-performance electronics, thermal management has become a critical bottleneck. Whether it’s a smartphone, a high-resolution display, or automotive lighting, LEDs generate significant heat during operation. Traditional heat sinks are bulky or inefficient at micro scales. That’s where graphene heat dissipation films come in—thin, flexible, and highly conductive, they’re quietly revolutionizing thermal design in modern optoelectronics.

🌟 Why Heat Management Matters in LEDs

LEDs are highly energy-efficient, but only a portion of input power is converted to light; the rest becomes heat. Excessive heat can:

- Reduce light output

- Shorten device lifespan

- Cause color shifting and flicker

Maintaining thermal stability is essential to ensure LED performance and reliability, especially in miniaturized or high-power applications.

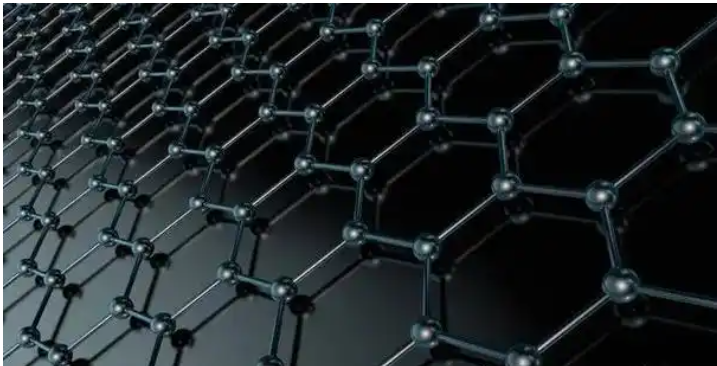

✨ Enter Graphene: The Ultralight Thermal Conductor

Graphene’s intrinsic thermal conductivity (~5000 W/m·K) is among the highest known. When fabricated into films or foils, graphene-based materials can effectively channel heat away from hotspots.

Key advantages:

- High in-plane thermal conductivity

- Mechanical flexibility for curved surfaces

- Lightweight and ultrathin

- Chemical stability under heat and moisture

These properties make graphene films ideal for integrating into LED packages, backplanes, and optical systems.

🔦 Use Case: Graphene in Mini-LED and Micro-LED Modules

Graphene heat spreaders are being deployed in:

- TV displays with dense micro-LED arrays

- Automotive headlights requiring precise thermal control

- Smartphones and wearables with limited internal space

By replacing or supplementing copper foils and ceramic substrates, graphene improves both thermal and weight performance.

🤖 How Are Graphene Heat Films Made?

Manufacturing techniques vary depending on the end-use:

- CVD-grown graphene on copper, transferred to flexible substrates

- Reduced graphene oxide (rGO) or graphene nanoplatelet composites

- Layer-by-layer coatings with polymer binders

These films can be laminated, coated, or embedded into LED structures using roll-to-roll or vacuum lamination techniques.

🔹 Performance Highlights

Recent studies and industrial reports show:

- 30–70% reduction in peak operating temperatures

- Enhanced luminous efficiency and color stability

- Lower thermal resistance compared to traditional thermal pads

In some cases, graphene hybrid films outperform synthetic graphite and metal-based heat spreaders.

⚖️ Challenges and Outlook

Despite their promise, commercialization faces hurdles:

- Cost of large-area, uniform graphene films

- Scalability and yield in flexible form factors

- Adhesion and reliability under thermal cycling

However, R&D is rapidly advancing. Companies are developing hybrid films combining graphene with boron nitride or aluminum nitride for tailored thermal and dielectric properties.

🚀 At GrapheneRich NanoTech

We offer custom graphene thermal films optimized for heat dissipation in electronics and lighting. Our rGO-CNT hybrid coatings can be tuned for both planar spreading and vertical conduction. With a focus on flexibility and integration, we help device makers push the limits of thermal design.

🌐 Conclusion

Graphene heat dissipation films are the invisible enablers behind cooler, brighter, and more reliable LEDs. As demand grows for thinner, more powerful electronic systems, graphene’s role in thermal management is set to shine.

Stay cool—go graphene.