Graphene Heating in EV Battery Thermal Management – Safety and Performance Benefits

Electric vehicle (EV) battery packs are becoming larger, denser, and more powerful—but also more thermally sensitive. As energy density increases and fast-charging becomes mainstream, effective battery thermal management systems (BTMS) have shifted from an optional performance enhancer to an absolute safety requirement.

Traditionally, BTMS relies on liquid cooling circuits, refrigerant loops, heat pipes, or PTC (positive temperature coefficient) heating elements. While functional, these approaches face distinct challenges when temperatures drop below 0 °C, when rapid temperature equalization is required, or when space inside the pack is limited.

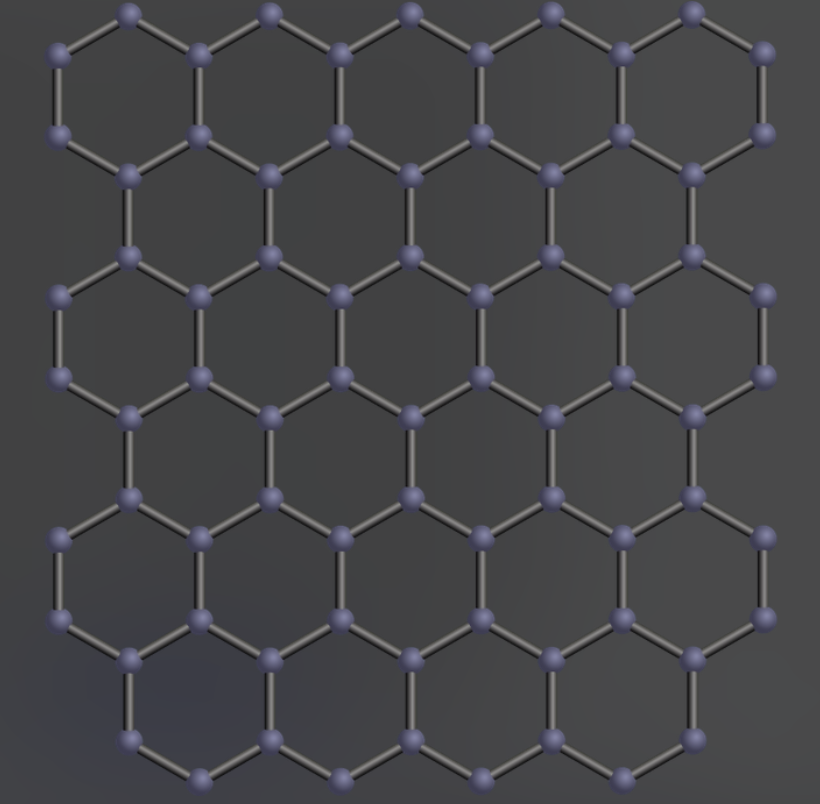

Graphene heating films—thin, lightweight, uniformly conductive—are emerging as a next-generation solution that addresses all major pain points of EV battery thermal management. Thanks to high electrical and thermal conductivity, durability, and tunable resistance, graphene heaters offer faster pre-heating, improved cell balance, and enhanced safety during extreme conditions.

This article explains how graphene heating films work inside EV battery packs, compares them with existing technologies, and highlights performance and safety benefits for automotive OEMs and battery integrators.

1. Why Battery Heating Matters: The Cold-Climate Problem

EV battery performance drops sharply at low temperatures. Lithium-ion cells become:

-

Slower to charge (risk of lithium plating below 0–5 °C)

-

Less efficient (higher internal resistance)

-

Lower in power output (reduced peak current capability)

-

More vulnerable during fast charging

Battery manufacturers now treat rapid pre-heating to above 10–15 °C as an essential requirement, especially for markets such as Canada, Northern Europe, and Northern China.

Current heating methods include:

PTC heaters

-

Slow warm-up

-

Heavy and bulky

-

Higher power consumption

-

Uneven temperature distribution

Liquid coolant heating

-

Relies on vehicle’s main thermal circuit

-

Slow start-up during cold soak

-

Circulating liquid may freeze or become highly viscous

Resistive wire heaters

-

Create local hotspots

-

Difficult to install uniformly

-

Poor long-term reliability under vibration

Graphene heating films solve these issues by offering a distributed, ultra-uniform heat source integrated directly onto module surfaces, cell sidewalls, or cold plates.

2. How Graphene Heating Films Work

Graphene heating films utilize either single-layer graphene, multi-layer graphene nanosheets, or graphene composites coated on PET/PI substrates. When low voltage is applied (typ. 12–48 V), the material converts electrical energy into heat via Joule heating.

Key characteristics

| Property | Why It Matters for EV Batteries |

|---|---|

| High thermal conductivity (600–1500 W/m·K) | Heat spreads evenly, preventing hotspots |

| Rapid heating rate | Fast cold-start, supports fast charging even at –20 °C |

| Thin and flexible (typically 20–200 µm) | Can be laminated inside tight battery module spaces |

| Low resistivity | Efficient heating with lower power draw |

| Temperature uniformity ±1–2 °C | Critical for cell-to-cell consistency and lifespan |

| Durability | Withstands vibration, swelling, freeze–thaw cycles |

Because graphene heaters are printed or laminated in flat-sheet form, they create a fully planar heat distribution, ideal for prismatic modules, pouch cells, or cold-plate integration.

3. Integration Options for EV Battery Packs

Graphene heating films can be added at several layers of a pack:

A. Cell-Level Integration

-

Laminated onto pouch cell surfaces

-

Attached to prismatic cell sidewalls

-

Sandwiched between cells in module arrays

Benefit: fastest reaction time and superior temperature uniformity across individual cells.

B. Module-Level Integration

-

Installed under or around module frames

-

Combined with graphite sheets or aluminum plates for spreading

-

Powered independently for zone-based heating

Benefit: Balanced performance & cost; integrates with existing cooling plates.

C. Pack-Level Integration

-

Graphene heaters built into cold plates

-

Used to pre-warm coolant or heating circuits

-

Powered by 12 V system during cold-soak or pre-conditioning

Benefit: compatible with current OEM designs without major structural changes.

4. Performance Benefits for EV OEMs and Battery Integrators

1. Faster Pre-Heating (2–5× Faster Than PTC)

Graphene films heat rapidly due to low thermal mass and high conductivity.

Real-world results show graphene-based pre-heating systems can raise cell temperatures from –20 °C to +10 °C in 5–10 minutes, compared to 20–30 minutes for PTC or coolant-based heating.

2. Lower Energy Consumption

Because heating is more uniform and efficient, graphene films typically require 20–40% less power to achieve the same temperature rise.

For EVs, this directly translates to:

-

Extended winter driving range

-

Reduced load on 12 V supply

-

Lower system-wide thermal losses

3. Uniform Temperature Distribution

Lithium plating during charging is triggered by local cold spots.

Graphene’s 2D structure naturally equalizes heat within the film, maintaining:

-

±2 °C temperature difference across an entire module

-

Improved SoC consistency

-

Longer cycle life of battery cells

4. Enhanced Safety: Reducing Lithium Plating Risk

Keeping cells uniformly above 0–5 °C during charging prevents:

-

metallic lithium deposition

-

dendrite growth

-

potential short circuits

This is especially critical for:

-

fast-charging EVs

-

LFP battery chemistries

-

cold-climate fleet vehicles

5. Lighter and Thinner BTMS Structure

A typical graphene heater is:

-

50–200 µm thick

-

<50 grams per module

This allows thinner modules or more energy-dense cell arrangements compared with bulky resistive heaters.

6. Improved Fast-Charging Performance

Uniform, targeted heating enables cells to stay within optimal temperature windows (20–40 °C).

This translates to:

-

shorter fast-charging time

-

better high-C-rate stability

-

consistent power delivery

7. High Durability Under Automotive Conditions

Graphene films withstand:

-

constant vibration

-

1,000+ freeze–thaw cycles

-

mechanical bending (beneficial for pouch modules)

-

humidity and chemical exposure

This reliability is crucial for long-term EV warranties.

5. Comparison with Conventional Heating Technologies

| Parameter | Graphene Heating Film | PTC Heater | Resistive Wire Heating |

|---|---|---|---|

| Heating Speed | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

| Temperature Uniformity | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ |

| Thickness | Ultra-thin | Thick | Moderate |

| Energy Efficiency | High | Medium | Low |

| Safety | Excellent | Good | Poor (risks hotspots) |

| Integrability in Packs | Very flexible | Rigid | Limited |

| Weight | Very light | Heavy | Medium |

Graphene heaters provide a step-change improvement, especially for next-generation battery designs targeting:

-

800 V architectures

-

solid-state batteries

-

ultra-fast charging (10–15 minutes)

-

high-density structural packs

6. Challenges & Considerations for OEM Adoption

While promising, OEMs must evaluate several practical considerations:

Cost

Graphene heaters cost more than resistive wires and slightly more than traditional PTC solutions.

However, total system savings arise from:

-

reduced warm-up times

-

higher range

-

lighter BTMS structures

-

improved fast-charging speed (customer value)

Supply Chain & Customization

Automotive integrators require:

-

High-volume production (hundreds of thousands of m²/year)

-

Consistent sheet resistance

-

Custom shapes & voltages

-

Automotive-grade encapsulation & UL/CE certifications

Companies like yours (Graphene Echo) providing custom films, OEM/ODM support, and module-level integration guidance can fill this gap.

Safety Certifications

Automotive-grade heaters must meet:

-

ISO 16750 (electrical load, vibration, thermal cycling)

-

AEC-Q200

-

UN38.3 compliance for module-level validation

Graphene films perform well, but long-term validation is still ongoing in many OEM programs.

7. Applications Beyond EVs

Graphene heating films also enhance thermal management in:

-

Hybrid vehicles

-

Plug-in hybrids

-

Electric buses

-

Industrial AGVs

-

Drone and eVTOL battery packs

-

Cold-climate energy storage systems

Any lithium-ion system operating below 0 °C benefits significantly from uniform, efficient pre-heating.

8. Why Graphene Heating Films Will Become Standard in Future EVs

Three trends guarantee widespread future adoption:

1. Fast Charging Requires Active Heating

As charging speeds move toward 5–10 minutes, uniform heating becomes mandatory to avoid plating.

2. Next-Gen Batteries Operate Within Narrower Thermal Windows

Solid-state and high-silicon anode batteries will need extremely precise thermal control.

3. Structural Battery Packs Need Thin, Lightweight Heaters

Graphene heaters integrate perfectly into CTP (cell-to-pack) and CTC (cell-to-chassis) architectures.