Graphene Hydrogels – Synthesis, Structure, and Applications

Understanding 3D Graphene Networks for Energy, Environment, and Biomedical Uses

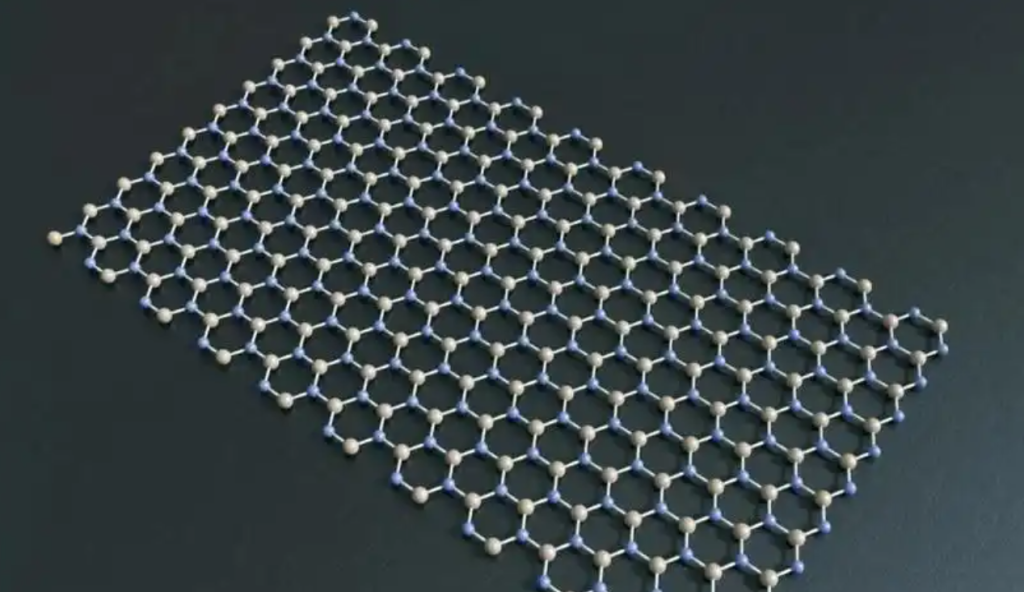

Graphene hydrogels are a unique class of three-dimensional (3D) porous materials constructed from interconnected graphene or graphene oxide (GO) sheets and water. Unlike conventional 2D graphene films or powders, graphene hydrogels exhibit high porosity, large surface area, mechanical flexibility, and excellent electrical conductivity, making them highly attractive for applications in energy storage, environmental remediation, sensors, and biomedical engineering.

This article introduces how graphene hydrogels are synthesized, how their structure influences performance, and where they are being applied at the industrial and research levels.

1. What Are Graphene Hydrogels?

Graphene hydrogels are water-rich, 3D graphene networks in which graphene or reduced graphene oxide (rGO) sheets are physically or chemically crosslinked to form a continuous porous scaffold. Water typically accounts for 90–99% of the total volume, while the solid graphene framework provides mechanical strength and functional properties.

Key characteristics include:

-

Ultra-high porosity (>95%)

-

Interconnected pore networks

-

Large specific surface area

-

Electrical conductivity (after reduction)

-

Mechanical elasticity and compressibility

These properties distinguish graphene hydrogels from traditional polymer hydrogels and aerogels.

2. Raw Materials: GO vs. Graphene

Most graphene hydrogels are produced from graphene oxide (GO) rather than pristine graphene due to GO’s excellent dispersibility in water.

Graphene Oxide (GO)

-

Rich in oxygen-containing functional groups (–OH, –COOH, –O–)

-

Easily dispersed in water

-

Enables hydrogen bonding and crosslinking

-

Can be reduced after gelation to improve conductivity

Reduced Graphene Oxide (rGO)

-

Higher electrical conductivity

-

Lower oxygen content

-

Often obtained via post-reduction of GO hydrogels

3. Synthesis Methods of Graphene Hydrogels

3.1 Self-Assembly (Hydrothermal Method)

This is the most common synthesis route.

Process:

-

Prepare a GO aqueous dispersion

-

Heat (typically 80–200°C) in a sealed autoclave

-

GO sheets partially reduce and self-assemble

-

A monolithic graphene hydrogel forms

Advantages:

-

Simple process

-

No external crosslinkers required

-

Good mechanical integrity

Limitations:

-

Limited control over pore size

-

Batch processing

3.2 Chemical Crosslinking

Crosslinking agents are introduced to link GO sheets.

Common crosslinkers:

-

Metal ions (Ca²⁺, Fe³⁺)

-

Polymers (PVA, PEG, chitosan)

-

Small molecules (ethylenediamine)

Benefits:

-

Tunable mechanical strength

-

Adjustable pore structure

-

Improved stability in liquids

Used extensively in biomedical and environmental applications.

3.3 Freeze-Drying Assisted Gelation

This method combines gelation with controlled freezing.

Steps:

-

Form GO gel

-

Freeze at controlled rate

-

Ice crystals template pore structure

-

Thaw or reduce to hydrogel

This technique allows anisotropic or aligned pore structures, useful for sensors and directional transport.

3.4 Electrochemical Reduction

GO is electrochemically reduced in situ to form conductive hydrogels directly on electrodes.

Applications:

-

Supercapacitors

-

Biosensors

-

Electrochemical devices

4. Structural Features and Property Control

4.1 Porosity and Pore Size

-

Macro-pores (µm–mm): fluid transport

-

Meso-pores (2–50 nm): ion diffusion

-

Micro-pores (<2 nm): adsorption and charge storage

Pore structure can be tuned by:

-

GO concentration

-

Crosslinker type

-

Freezing rate

-

Reduction degree

4.2 Mechanical Properties

Despite high water content, graphene hydrogels can be:

-

Highly elastic

-

Compressible up to 80–90%

-

Shape-recoverable after deformation

This makes them suitable for wearable sensors and soft electronics.

4.3 Electrical Conductivity

Conductivity depends on reduction level:

-

GO hydrogel: insulating

-

rGO hydrogel: conductive (10⁻²–10² S/m)

Conductive hydrogels enable electrochemical and sensing applications.

5. Key Applications of Graphene Hydrogels

5.1 Energy Storage (Supercapacitors & Batteries)

Graphene hydrogels are ideal electrode materials due to:

-

Continuous electron pathways

-

Short ion diffusion distances

-

High active surface area

Used in:

-

Supercapacitor electrodes

-

Flexible energy storage devices

-

Lithium–sulfur and sodium-ion batteries

Performance benefits:

-

High capacitance

-

Fast charge/discharge

-

Long cycle life

5.2 Environmental Remediation

Graphene hydrogels can absorb:

-

Oils and organic solvents

-

Heavy metal ions

-

Dyes and pollutants

Advantages:

-

High adsorption capacity

-

Easy recovery (monolithic structure)

-

Reusable after washing or burning

Used in:

-

Oil spill cleanup

-

Industrial wastewater treatment

5.3 Sensors and Wearable Electronics

Due to their elasticity and conductivity, graphene hydrogels are used in:

-

Strain sensors

-

Pressure sensors

-

Motion detection devices

-

Health monitoring wearables

Their sensitivity arises from resistance changes under deformation.

5.4 Biomedical Applications

When combined with biocompatible polymers, graphene hydrogels are explored for:

-

Tissue engineering scaffolds

-

Drug delivery systems

-

Wound dressings

-

Biosensors

Key features:

-

Porous structure promotes cell growth

-

Functionalizable surface

-

Controlled drug release

5.5 Catalysis and Electrocatalysis

Graphene hydrogels act as:

-

Catalyst supports

-

Electrocatalyst frameworks

Used in:

-

Fuel cells

-

Water splitting

-

Oxygen reduction reactions (ORR)

Their 3D structure prevents catalyst aggregation and improves mass transport.

6. Challenges and Limitations

Despite their advantages, graphene hydrogels face several challenges:

-

Mechanical fragility under long-term load

-

Scalability of controlled synthesis

-

Cost and consistency of high-quality GO

-

Drying sensitivity (structure collapse if dehydrated improperly)

Industrial applications often require composite hydrogels to overcome these issues.

7. Market Trends and Future Outlook

-

Growing demand in flexible energy storage and wearable electronics

-

Increasing research in biomedical-grade hydrogels

-

Integration with CNTs, polymers, and metal oxides for multifunctionality

-

Transition from lab-scale monoliths to roll-to-roll and moldable formats

Graphene hydrogels are moving steadily from academic research into niche industrial applications, with strong long-term potential.

Graphene hydrogels represent a powerful evolution from 2D graphene materials to functional 3D architectures. Their combination of porosity, conductivity, and mechanical flexibility opens new possibilities in energy storage, environmental protection, sensing, and biomedical engineering. As synthesis techniques mature and scalability improves, graphene hydrogels are expected to become a key material platform in next-generation technologies.