Graphene in 3D Printing Materials: Revolutionizing Additive Manufacturing

The world of 3D printing, also known as additive manufacturing, is advancing at an extraordinary pace, reshaping industries from healthcare and aerospace to automotive and consumer products. At the same time, graphene, often called the “wonder material,” has emerged as one of the most promising nanomaterials due to its unmatched strength, conductivity, and versatility.

The integration of graphene into 3D printing materials represents a powerful synergy. Graphene enhances polymers, resins, and composites used in 3D printing, enabling the creation of lighter, stronger, more functional components. This convergence is driving the next generation of functional 3D-printed parts, moving beyond prototypes toward high-performance end-use products.

Why Graphene in 3D Printing?

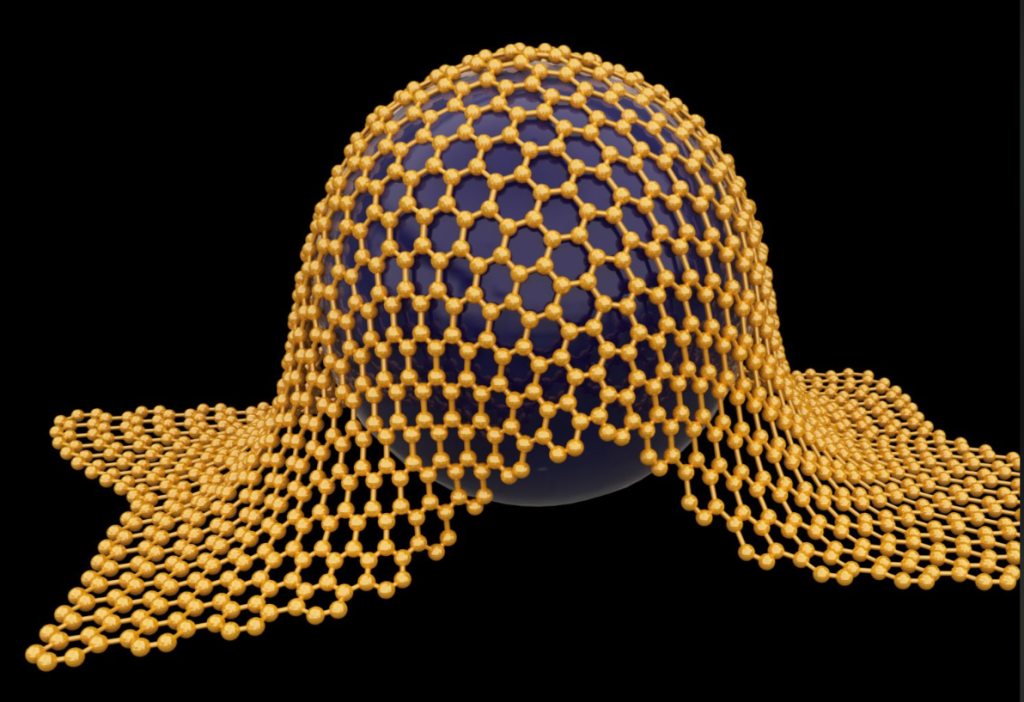

Graphene is a one-atom-thick sheet of carbon atoms arranged in a hexagonal lattice, giving it extraordinary properties:

-

Mechanical Strength: Over 200 times stronger than steel, yet flexible.

-

Electrical Conductivity: Excellent electron mobility, making composites conductive.

-

Thermal Conductivity: Efficient heat dissipation.

-

Lightweight: Adds performance without adding weight.

-

Surface Area: High aspect ratio allows strong interaction with polymer matrices.

These features make graphene an ideal additive for 3D printing materials, particularly when blended into thermoplastics, resins, and composites.

Types of Graphene-Enhanced 3D Printing Materials

1. Graphene-Polymer Filaments

Polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), and nylon are widely used in FDM (Fused Deposition Modeling). By adding graphene:

-

Filaments become stronger and more durable.

-

Printed objects exhibit improved electrical and thermal conductivity.

-

Better layer adhesion and reduced warping occur during printing.

2. Graphene-Resin Composites

In SLA (Stereolithography) and DLP (Digital Light Processing) printing, graphene-infused resins provide:

-

Higher mechanical stability of printed structures.

-

Conductive pathways for electronics and sensors.

-

Enhanced heat resistance for industrial applications.

3. Graphene Aerogels and Foams

3D-printed graphene aerogels exhibit ultra-lightweight structures with applications in:

-

Energy storage (supercapacitors, batteries).

-

Filtration and water purification.

-

Thermal insulation for aerospace.

4. Hybrid Graphene Composites

Graphene combined with carbon fibers, nanotubes, or ceramics in 3D printing produces multi-functional composites—ideal for aerospace, automotive, and defense.

Key Applications of Graphene in 3D Printing

1. Aerospace and Automotive

-

Lightweight graphene composites reduce fuel consumption.

-

Heat-resistant printed parts withstand extreme operating conditions.

-

Embedded graphene sensors allow structural health monitoring.

2. Healthcare and Bioprinting

-

Graphene’s biocompatibility and antibacterial properties make it suitable for implants.

-

Conductive scaffolds enable nerve regeneration and tissue engineering.

-

Customized prosthetics benefit from enhanced durability and lighter weight.

3. Electronics and Wearables

-

Graphene filaments enable conductive 3D-printed circuits.

-

Wearable sensors and smart textiles integrate graphene for flexibility and conductivity.

-

Rapid prototyping of IoT devices becomes feasible.

4. Construction and Architecture

-

Graphene-enhanced cement and composites printed via large-scale 3D printing improve strength, durability, and insulation.

-

Future smart building materials with embedded conductivity and sensing capabilities.

5. Energy Storage Devices

-

Graphene aerogels printed into battery electrodes offer high surface area.

-

Supercapacitors with graphene structures deliver fast charge/discharge cycles.

Research Highlights and Case Studies

-

University of Manchester: Developed graphene-enhanced PLA filaments with 30% improved mechanical strength.

-

Graphene 3D Lab (Canada): Commercialized graphene-based conductive filaments for 3D-printed circuits.

-

Chinese Research Teams: 3D-printed graphene aerogels for water purification with excellent adsorption capacity.

-

NASA: Explored graphene composites in 3D printing for lightweight aerospace structures.

These breakthroughs demonstrate graphene’s ability to move 3D printing beyond prototyping into functional manufacturing.

Advantages of Graphene-Enhanced 3D Printing Materials

-

Stronger and More Durable: Enhances mechanical stability.

-

Conductive: Enables electrical and thermal functionalities.

-

Lightweight: Maintains performance while reducing material usage.

-

Versatile: Applicable across multiple 3D printing methods.

-

Scalable: Graphene powders, flakes, and inks can be integrated into existing supply chains.

Market Potential

The global 3D printing materials market is projected to surpass USD 10 billion by 2030, with rapid adoption in aerospace, automotive, and healthcare.

Simultaneously, the graphene market is expected to reach USD 3–4 billion by 2032, with composites being the largest growth sector.

Combining these two technologies positions graphene-enhanced 3D printing materials as a high-growth opportunity within both industries.

Challenges to Overcome

-

Dispersion Issues: Ensuring even distribution of graphene in polymers.

-

Cost: Graphene materials are still more expensive than conventional additives.

-

Standardization: Lack of industrial standards for graphene-based 3D printing filaments and resins.

-

Processing Compatibility: Balancing graphene content with printability and mechanical performance.

Ongoing research aims to address these barriers through functionalized graphene, hybrid composites, and scalable manufacturing methods.

Future Outlook

The integration of graphene into 3D printing materials is set to accelerate in the coming decade. We can expect:

-

Mass Adoption in Aerospace: Lighter, stronger parts with embedded sensing.

-

Smart Prosthetics: Biocompatible, conductive implants tailored to patients.

-

Energy Devices: 3D-printed batteries and supercapacitors with graphene electrodes.

-

Construction: 3D-printed houses with graphene-enhanced concrete for sustainability.

-

Consumer Electronics: Rapid prototyping of functional devices with built-in conductivity.

As costs decline and standards develop, graphene in 3D printing will unlock an era of multifunctional, sustainable, and high-performance manufacturing.

The convergence of graphene and 3D printing is unlocking transformative opportunities across industries. By enhancing polymers, resins, and composites with graphene, manufacturers can create lighter, stronger, more conductive, and more durable 3D-printed parts.

From aerospace and healthcare to energy storage and construction, graphene-based 3D printing materials are pushing additive manufacturing into new frontiers. While challenges remain in scalability and cost, the future points toward graphene-enabled functional manufacturing as a cornerstone of advanced industry.

✅ Recent Articles You May Like