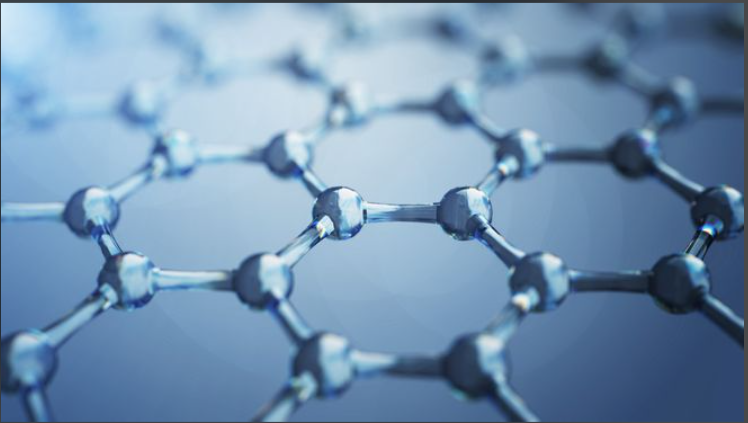

Graphene in Advanced Thermal Interface Materials (TIMs) for Electronics Cooling

As electronic devices become increasingly compact and powerful, thermal management has emerged as one of the most critical engineering challenges. Whether it’s smartphones, high-performance computing systems, or electric vehicle (EV) batteries, managing heat efficiently is essential to ensure device reliability, safety, and performance. Graphene, with its extraordinary thermal conductivity and mechanical flexibility, is redefining the capabilities of Thermal Interface Materials (TIMs) used in next-generation electronics.

Why Thermal Interface Materials Matter

In most electronics, heat must be transferred away from hotspots (like CPUs or power modules) to heat sinks or spreaders. TIMs are used to fill microscopic air gaps between these surfaces, ensuring maximum thermal contact.

An ideal TIM must possess:

-

High thermal conductivity

-

Conformability to surfaces

-

Electrical insulation (in most cases)

-

Mechanical and chemical stability

Traditional TIMs such as silicone grease or polymer pads often fail under high-performance demands. Enter graphene.

What Makes Graphene a Game-Changer for TIMs

Graphene exhibits thermal conductivity up to 5300 W/m·K, far exceeding that of copper or diamond. Its atomically thin nature allows it to fill gaps at the nanoscale, improving surface contact and reducing thermal resistance.

Other key benefits:

-

Flexible and durable under mechanical stress

-

Electrically tunable for insulating or conductive applications

-

Compatible with polymers, epoxies, and composites

Graphene-Based TIM Technologies

1. Graphene Foils and Sheets

Thin, highly aligned graphene sheets are used as direct replacement for graphite pads. These provide high in-plane thermal conductivity for smartphones, LED modules, and processors.

2. Graphene-Enhanced Thermal Pastes

Graphene nanoplatelets or reduced graphene oxide are dispersed in polymeric bases to create high-performance pastes that outperform silver or ceramic-based greases.

3. Graphene Aerogels and Sponges

Used in EV battery packs and wearable devices, graphene-based aerogels combine high thermal conductivity with low weight and compressibility.

Industry Applications

-

5G smartphones and tablets

-

LED lighting modules

-

Power inverters and converters

-

EV battery modules and charging systems

-

High-performance computing (HPC) servers

Commercial Products in Development

Several companies now offer graphene-enhanced TIMs in the market:

-

Henkel Loctite: Graphene-infused pads

-

GrapheneCA: Custom formulations for automotive cooling

-

Zymergen and Samsung: R&D in stacked chip cooling for AI processors

Challenges & Considerations

-

Scalability and cost of high-quality graphene

-

Uniform dispersion in composite matrices

-

Electrical conductivity risks where insulation is required

Future Trends

-

Integration into flexible electronics

-

TIMs that double as EMI shielding layers

-

Phase-change graphene materials for smart thermal regulation

Graphene is propelling thermal management technology into a new era. Its integration into TIMs represents a major leap forward in electronics reliability, energy efficiency, and miniaturization. As devices continue to shrink and power densities rise, graphene-based TIMs will become the new standard.