Graphene in Anti-Corrosion Coatings: A Breakthrough in Surface Protection

Corrosion is a costly and persistent challenge in industries such as marine, automotive, aerospace, energy, and infrastructure. It leads to structural degradation, reduced performance, safety risks, and billions of dollars in maintenance costs each year. Traditional anti-corrosion coatings—such as paints, epoxy resins, and metal platings—provide some protection, but they often degrade over time, especially in harsh environments.

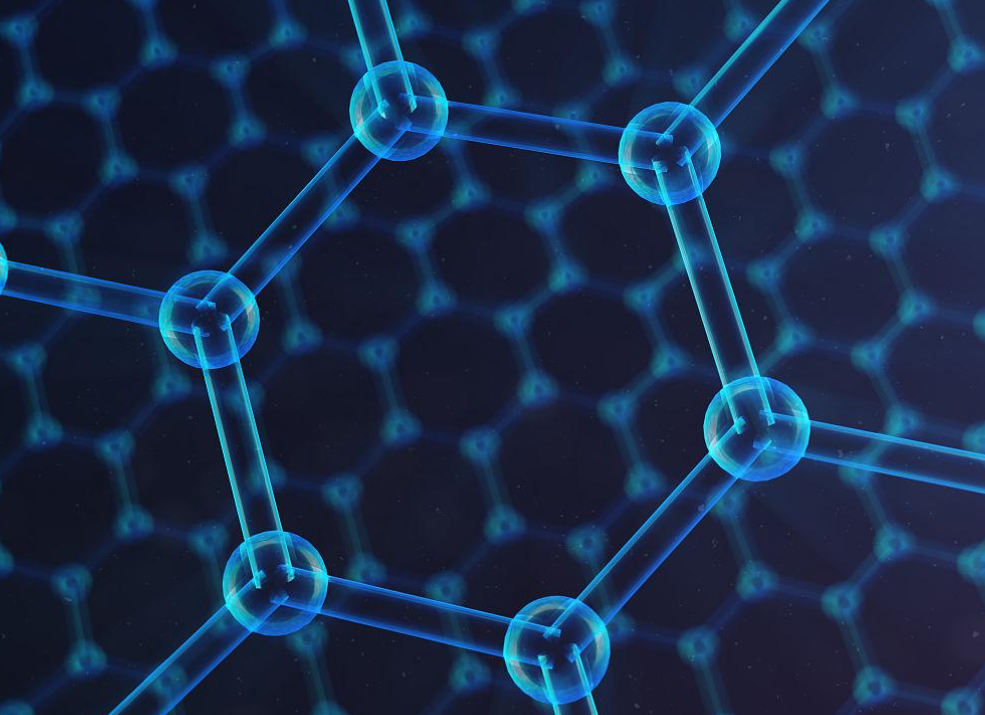

Enter graphene, a one-atom-thick sheet of carbon atoms arranged in a honeycomb lattice. Known for its exceptional strength, impermeability, electrical conductivity, and chemical stability, graphene has emerged as a revolutionary material for anti-corrosion coatings. By integrating graphene into paints, polymers, and composite coatings, industries can achieve long-lasting, lightweight, and eco-friendly corrosion resistance.

Why Graphene for Anti-Corrosion?

Graphene provides several unique advantages that make it superior to conventional anti-corrosion solutions:

-

Impermeability → Graphene is nearly impermeable to gases and liquids, preventing oxygen and moisture from reaching metal surfaces.

-

Barrier Protection → Its two-dimensional structure creates a tortuous path effect, slowing down corrosive agent diffusion.

-

Chemical Stability → Graphene resists harsh chemicals, acids, and salts.

-

Mechanical Strength → Reinforces coatings, making them more durable against wear and tear.

-

Lightweight → Provides protection without adding bulk or weight.

-

Eco-Friendly Potential → Reduces reliance on toxic heavy metals and solvent-based coatings.

These properties allow graphene coatings to extend the lifespan of critical infrastructure, reduce maintenance costs, and improve sustainability.

Mechanisms of Graphene Anti-Corrosion Protection

1. Barrier Effect

Graphene forms a dense, impermeable shield over metal surfaces, blocking oxygen, water, and chloride ions from initiating rust.

2. Tortuous Path

When dispersed in a polymer matrix, graphene creates a maze-like diffusion path that slows down corrosive molecules.

3. Electrical Conductivity

Graphene’s conductivity can enable cathodic protection and self-healing properties in hybrid coatings.

4. Synergistic Reinforcement

Graphene improves adhesion, mechanical durability, and UV resistance of conventional coatings, extending performance.

Applications of Graphene in Anti-Corrosion Coatings

1. Marine Industry

-

Ships, offshore platforms, and pipelines face constant exposure to saltwater.

-

Graphene coatings prevent rust, pitting, and biofouling more effectively than traditional paints.

-

Extends maintenance intervals for fleets and offshore rigs.

2. Automotive and Transportation

-

Graphene-infused coatings protect chassis, fuel tanks, and underbody components from road salt and moisture.

-

Enables lightweight, high-performance corrosion protection for electric vehicles (EVs).

3. Aerospace and Defense

-

Aircraft and military vehicles require lightweight coatings resistant to harsh climates.

-

Graphene coatings provide protection while maintaining fuel efficiency.

4. Oil, Gas, and Energy

-

Graphene protects pipelines, storage tanks, and wind turbines from corrosion.

-

Reduces downtime and costly repairs in energy infrastructure.

5. Civil Infrastructure

-

Bridges, rebar in concrete, and structural steel benefit from graphene protective layers.

-

Prevents premature deterioration and improves urban resilience.

Case Studies and Research Highlights

-

University of Manchester: Developed graphene-based coatings that outperformed standard epoxy paints in salt-spray tests.

-

Indian Institute of Technology: Demonstrated graphene oxide coatings that prevented steel corrosion for over six months in seawater exposure.

-

Commercial Coating Companies: Several startups are already marketing graphene-enhanced paints and primers for automotive and marine applications.

-

European Union Projects: Large-scale trials underway for graphene protective coatings in civil infrastructure.

Advantages of Graphene Anti-Corrosion Coatings

-

Long-Lasting Protection → Extends lifespan of metals in harsh environments.

-

Lightweight → Essential for aerospace and automotive sectors.

-

Cost Savings → Reduced maintenance, repair, and replacement costs.

-

Environmental Benefits → Potential replacement for toxic chromates and heavy metals.

-

Versatility → Compatible with paints, polymers, sprays, and composite coatings.

-

Multi-Functional → Adds not just corrosion resistance, but also mechanical strength, UV protection, and thermal stability.

Market Potential

The global anti-corrosion coatings market is projected to exceed USD 40 billion by 2032. With stricter environmental regulations and demand for sustainable solutions, graphene coatings are positioned to capture a significant market share.

Industries expected to benefit most include:

-

Marine & Shipping → Extended vessel lifespan.

-

Automotive & EVs → Lightweight protective coatings.

-

Aerospace & Defense → Fuel-efficient anti-corrosion solutions.

-

Oil & Gas → Longer pipeline protection.

-

Civil Infrastructure → Durable bridges, highways, and rebar reinforcement.

Challenges and Considerations

Despite its promise, graphene anti-corrosion technology faces hurdles:

-

Production Cost → High-quality graphene remains expensive.

-

Dispersion Issues → Achieving uniform graphene distribution in coatings is difficult.

-

Standardization → Lack of universal testing standards for graphene coatings.

-

Scalability → Large-scale manufacturing processes are still maturing.

-

Regulatory Barriers → Safety and environmental regulations need to adapt to nanomaterials.

Future Outlook

Graphene anti-corrosion coatings are rapidly moving from laboratory research to industrial applications. The future may include:

-

Smart Coatings → Graphene-enabled coatings that self-heal or indicate corrosion onset.

-

Hybrid Coatings → Graphene combined with polymers, metals, or nanocomposites for superior performance.

-

Mass Adoption in Automotive and EVs → As costs decrease, graphene coatings could become standard.

-

Infrastructure Renewal → Governments may integrate graphene coatings in bridge and highway projects.

-

Green Alternatives → Replacement of toxic chromates and environmentally harmful coatings.

Over the next decade, graphene will likely play a defining role in sustainable corrosion protection, reshaping industries from shipping to aerospace.

Graphene in anti-corrosion coatings offers a game-changing solution to one of the biggest industrial challenges: metal degradation. With its unparalleled impermeability, mechanical strength, and stability, graphene can dramatically extend the life of ships, vehicles, pipelines, and infrastructure.

Although challenges such as cost and scalability remain, ongoing research and commercialization efforts are accelerating adoption. As industries embrace sustainability and cost efficiency, graphene-enhanced coatings are set to become the gold standard in corrosion protection.

The result? Longer-lasting materials, reduced environmental impact, and billions saved in maintenance costs—all powered by the remarkable potential of graphene.