Graphene in Bio-Based Plastics Enhancement: Toward Stronger, Greener Materials

As the world shifts toward sustainability, bio-based plastics have become a vital alternative to conventional petroleum-based polymers. These materials, derived from renewable sources such as corn, sugarcane, or algae, offer a path to reducing dependence on fossil fuels and cutting carbon emissions. However, bio-based plastics still face significant challenges, including lower mechanical strength, poor barrier properties, and limited durability, which restrict their widespread adoption in packaging, automotive, and electronics.

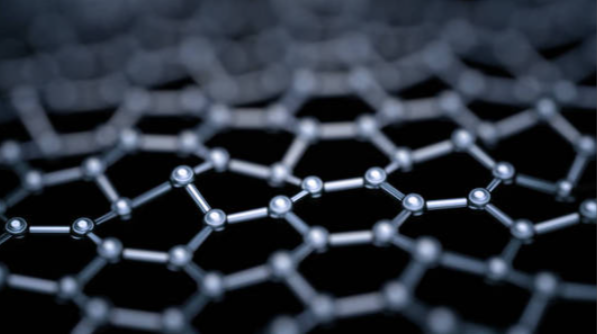

Enter graphene, a revolutionary nanomaterial consisting of a single layer of carbon atoms arranged in a honeycomb lattice. With its exceptional strength, conductivity, and barrier properties, graphene has emerged as a powerful enhancer for bio-based plastics. By integrating graphene into biopolymer matrices, industries can create lightweight, durable, and high-performance composites that combine sustainability with advanced functionality.

Why Graphene for Bio-Based Plastics?

Bio-based plastics, while eco-friendly, typically lack the strength, thermal stability, and gas resistance of petroleum-derived polymers. Graphene helps overcome these limitations by providing:

-

Mechanical Reinforcement → Graphene’s strength (~200x stronger than steel) boosts durability.

-

Barrier Properties → Prevents gas and moisture penetration, extending shelf life in packaging.

-

Thermal Stability → Improves resistance to heat, enabling broader applications.

-

Electrical Conductivity → Adds functionality for electronics and sensors.

-

Lightweight Design → Enhances performance without adding bulk.

-

Eco-Synergy → Both graphene and bio-based plastics align with sustainability goals.

The synergy between renewable plastics and graphene nanotechnology creates materials that are not only greener but also more competitive with traditional polymers.

Mechanisms of Graphene Enhancement in Bioplastics

1. Mechanical Strengthening

Graphene sheets form strong interactions with biopolymer chains, reinforcing the plastic and improving tensile strength and toughness.

2. Barrier Enhancement

Graphene layers create a tortuous path that slows down the diffusion of oxygen, carbon dioxide, and water vapor, which is critical for food packaging applications.

3. Thermal and UV Resistance

Graphene improves heat resistance and UV shielding, preventing premature degradation of bioplastics.

4. Electrical Functionality

By incorporating conductive graphene, bio-based plastics can serve as flexible electronic substrates, antistatic packaging, or smart labels.

5. Antibacterial Properties

Graphene-infused bioplastics can resist microbial growth, which is especially useful in medical and food-contact applications.

Applications of Graphene-Enhanced Bio-Based Plastics

1. Sustainable Packaging

-

Food and beverage packaging benefits from extended shelf life due to improved barrier properties.

-

Lightweight yet strong packaging reduces transportation costs and waste.

2. Automotive and Aerospace Components

-

Graphene-enhanced bioplastics replace heavier petroleum-based plastics.

-

Provide lightweight, strong, and heat-resistant materials for interiors, panels, and trims.

3. Consumer Electronics

-

Bioplastics with graphene can serve as casings, circuit substrates, and antistatic components.

-

Enable more sustainable electronic products.

4. Medical Devices and Biocompatible Materials

-

Antimicrobial graphene bioplastics are ideal for surgical tools, implants, and disposable medical products.

-

Offer both strength and safety in clinical use.

5. 3D Printing Filaments

-

Graphene-bioplastic composites are excellent for additive manufacturing, offering improved printability and functional properties.

Case Studies and Research Highlights

-

University of Exeter (UK): Developed PLA-graphene composites with enhanced conductivity, opening opportunities for 3D-printed electronics.

-

Chinese Academy of Sciences: Demonstrated graphene in starch-based bioplastics, significantly improving mechanical strength and thermal resistance.

-

European Packaging Research: Graphene nanocomposites in biodegradable films extended food shelf life by reducing oxygen transmission.

-

Commercial Startups: Companies are actively exploring graphene-infused biopolymer packaging to replace single-use plastics.

Advantages of Graphene-Bioplastic Composites

-

High Strength & Durability → Competitive with petroleum plastics.

-

Improved Shelf Life → Superior gas and moisture barrier properties.

-

Lightweight Design → Reduces transportation costs and emissions.

-

Eco-Friendly → Combines renewable bioplastics with advanced nanomaterials.

-

Functional Add-ons → Conductivity, antibacterial behavior, and UV shielding.

-

Compatibility with Manufacturing → Suitable for extrusion, injection molding, and 3D printing.

Market Potential

The global bioplastics market is projected to exceed USD 25 billion by 2032, driven by sustainability regulations and consumer demand.

Meanwhile, the graphene market is expected to grow to USD 3–4 billion by 2032, with packaging and composites as major sectors.

The integration of graphene into bio-based plastics represents a high-growth niche, targeting industries such as:

-

Food and beverage packaging → sustainable alternatives to PET and PE.

-

Automotive and aerospace → lightweight composites.

-

Medical devices → safe, antimicrobial bioplastics.

-

Electronics and 3D printing → functional, sustainable materials.

Challenges and Considerations

-

Cost of Graphene → High-quality graphene remains relatively expensive.

-

Dispersion Issues → Achieving uniform graphene distribution in polymers is challenging.

-

Scalability → Large-scale processing must maintain consistent performance.

-

End-of-Life Management → More research needed on biodegradability with graphene additives.

-

Regulatory Approval → Packaging and medical uses require safety validation.

Future Outlook

In the coming decade, graphene-enhanced bioplastics are expected to become a mainstream material. Likely advancements include:

-

Commercial Packaging Adoption → Supermarkets and brands shifting to graphene biopolymer films.

-

Automotive Lightweighting → CNT/graphene composites replacing petroleum plastics in vehicles.

-

Smart Sustainable Packaging → Bioplastics with embedded sensors and conductivity for real-time monitoring.

-

Medical Applications → Widespread use in biocompatible implants and antimicrobial tools.

-

Scalable Manufacturing → Roll-to-roll processing and 3D printing with graphene bioplastic feedstocks.

Graphene will not only enhance the mechanical and functional properties of bioplastics but also accelerate the global transition to circular and sustainable materials.

Graphene in bio-based plastics enhancement represents a powerful solution to bridge the gap between sustainability and performance. By reinforcing bio-derived polymers with graphene, industries can create materials that are stronger, lighter, and more durable, while also offering new functionalities such as barrier resistance, conductivity, and antibacterial properties.

From packaging and automotive to medical devices and electronics, graphene-bioplastic composites are set to transform multiple industries, driving a shift toward eco-friendly yet high-performance materials. While cost and scalability challenges remain, the momentum is clear: graphene will play a key role in the future of sustainable materials innovation.