Graphene in Conductive Inks: Enabling the Future of Flexible and Printed Electronics

Introduction

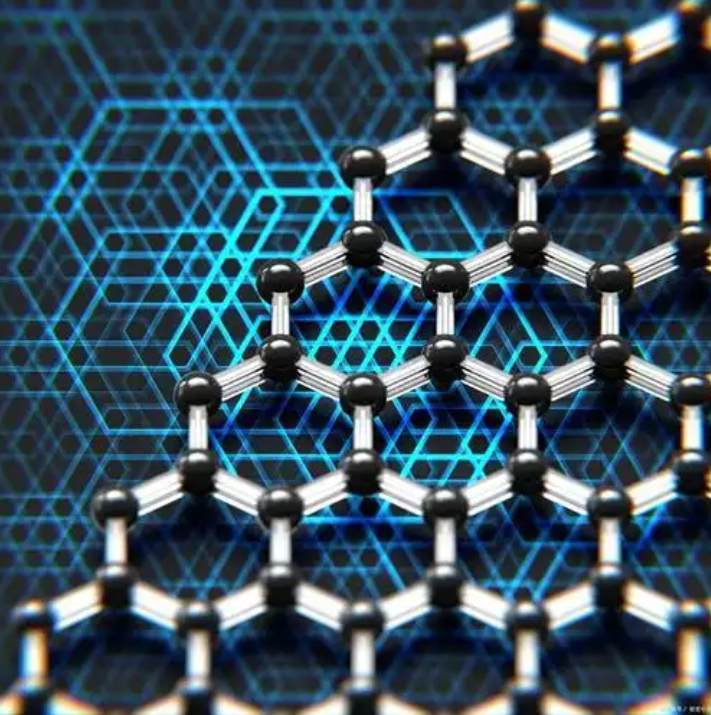

As the demand for flexible, wearable, and printed electronics continues to grow, conventional metal-based conductive inks are reaching their limits in terms of flexibility, cost, and long-term performance. Graphene, with its exceptional electrical conductivity, mechanical strength, and processability, is now being adopted in commercial conductive ink formulations across various industries.

In China, several companies and academic institutes have successfully developed and mass-produced graphene-based conductive inks, which are already being used in RFID antennas, touch panels, smart packaging, sensors, and even flexible solar cells.

What Are Conductive Inks and Why Graphene?

Conductive inks are printable or coatable formulations that allow electronic circuits to be deposited on a variety of substrates. Traditional materials include silver nanoparticles, copper, or carbon black.

Graphene offers multiple advantages:

-

High electrical conductivity (~10⁶ S/m)

-

Ultra-thin flakes enable smooth, low-resistance films

-

Excellent flexibility and stretchability

-

Low-temperature curing, suitable for plastic substrates

-

Cost efficiency vs. silver inks

Types of Graphene Conductive Inks

-

Water-based graphene inks (eco-friendly, screen/inkjet printable)

-

Solvent-based graphene inks (higher dispersion stability)

-

Graphene hybrid inks (with silver nanowires, CNTs for synergy)

-

UV-curable graphene coatings (for fast production lines)

These can be tailored for:

-

Screen printing

-

Inkjet printing

-

Gravure and flexographic processes

-

Aerosol and spray deposition

Key Properties for End-Use

| Property | Graphene Ink | Silver Ink | Carbon Ink |

|---|---|---|---|

| Sheet Resistance | <10 Ω/sq | <0.1 Ω/sq | >100 Ω/sq |

| Flexibility (bending cycles) | >1000 | <500 | >1000 |

| Cost (per gram) | Low to moderate | High | Low |

| Substrate Compatibility | Plastic, paper, textile | Plastic only | Plastic, paper |

Applications in Mass Production

1. Flexible Sensors

-

Domestic graphene inks are used in strain sensors, pressure sensors, biosensors

-

Commonly screen-printed on TPU, PET, or textile substrates

-

Used in smart wearables, sports monitoring bands, medical patches

2. RFID and NFC Antennas

-

Printed on paper or flexible plastic

-

Graphene ink enables cost-effective high-volume production

-

Compatible with environmental packaging and smart logistics

3. Touch Panels and Transparent Conductive Layers

-

Large-area printing on glass or plastic for capacitive touch

-

Used in e-readers, smart cards, tablets

4. Smart Packaging and Anti-Counterfeiting

-

Embedded conductive circuits for temperature sensing, traceability

-

Printed directly on cardboard or plastic wraps

China’s Domestic Industry Progress

Chinese ink formulators and graphene producers have jointly advanced production via:

-

Roll-to-roll compatible printing processes

-

Functionalized graphene for stable dispersion

-

Low curing temperatures (<100°C) for plastic substrates

Example capabilities:

-

Sheet resistance: ~10–30 Ω/sq at 10 μm thickness

-

Print width: Up to 600 mm in industrial lines

-

Substrates: PET, PI, textiles, paper, glass

Key cities: Suzhou, Ningbo, Hangzhou, Wuxi

Collaborators: Local universities + printing OEMs

Case Study: Printed Wearable ECG Sensor Patch

A startup based in eastern China uses graphene ink to screen-print flexible ECG electrodes directly onto fabric or medical-grade films. The sensors withstand:

-

1000+ bending cycles

-

Over 48 hours of skin contact

-

Real-time heart rate and activity tracking

It has received funding from hospital pilot programs and wearable health device integrators.

Advantages Over Metal-Based Inks

-

No metal migration or oxidation

-

Lower cost (no precious metals)

-

Better adhesion to textiles and curved surfaces

-

Safer for skin-contact medical use

Challenges and Development Needs

-

Dispersion control: Avoiding aggregation of graphene sheets

-

Standardization: Variability in conductivity between batches

-

Curing optimization: Some inks still need high-temperature sintering

Future innovation directions include:

-

Self-healing graphene circuits

-

Biocompatible formulations

-

Graphene quantum dot inks for display printing

Conclusion

Graphene-based conductive inks are no longer just an academic curiosity—they are now a critical component in China’s emerging printed electronics ecosystem. With continued optimization and deeper integration into mass production lines, graphene inks will become an enabler of next-generation smart, flexible, and wearable devices.

China’s ability to scale these technologies while keeping costs low and quality consistent will play a decisive role in whether flexible electronics reaches its true commercial potential.