Graphene in Electric Vehicle Battery Anodes: A Path to Higher Performance

The electric vehicle (EV) market is growing rapidly worldwide, driving demand for high-performance batteries. While lithium-ion batteries dominate the current landscape, traditional graphite anodes face limitations in terms of energy density, charging speed, and cycle life.

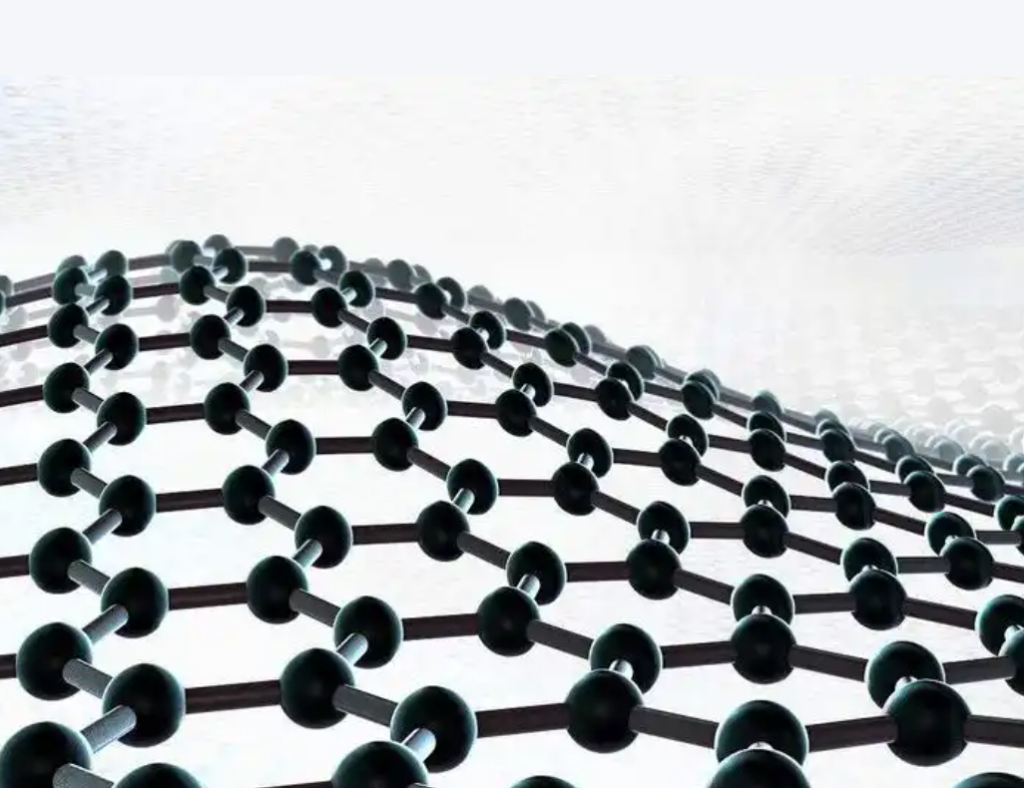

Graphene-enhanced anodes are emerging as a next-generation solution. With its two-dimensional structure, ultra-high conductivity, and mechanical strength, graphene has the potential to significantly improve EV battery performance. This article explores the role of graphene in EV anodes, its benefits, challenges, and commercialization trends.

1. Limitations of Conventional Graphite Anodes

-

Energy Density Ceiling

-

Graphite anodes typically achieve a theoretical capacity of 372 mAh/g.

-

This restricts the driving range of EVs.

-

-

Charging Speed

-

Graphite’s ion diffusion rate is limited, leading to slow charging cycles and risk of lithium plating at high currents.

-

-

Cycle Life Degradation

-

Graphite expands and contracts during cycling, causing structural damage and capacity fade.

-

These drawbacks highlight the need for advanced materials to meet EV market expectations.

2. Why Graphene? Unique Material Properties

Graphene offers several advantages over traditional carbon materials:

-

High Electrical Conductivity – enhances charge transfer efficiency

-

Large Surface Area (2,600 m²/g) – supports higher ion storage capacity

-

Mechanical Strength – resists structural degradation during cycling

-

Thermal Conductivity – helps maintain stable battery temperatures under fast-charging conditions

By incorporating graphene into the anode, EV batteries can achieve faster charging, higher capacity, and longer lifespan.

3. Approaches to Graphene-Based EV Anodes

-

Graphene-Modified Graphite Anodes

-

Adding graphene layers to graphite particles improves conductivity and lithium-ion diffusion.

-

Compatible with existing manufacturing lines.

-

-

Graphene-Silicon Composite Anodes

-

Silicon offers a theoretical capacity of ~3,500 mAh/g but suffers from volume expansion.

-

Graphene acts as a buffer matrix, reducing structural damage.

-

-

Pure Graphene or 3D Graphene Networks

-

Enable ultra-fast charging due to interconnected conductive channels.

-

Still in early-stage research and pilot production.

-

4. Performance Benefits for EV Batteries

-

Higher Energy Density

-

Graphene-enhanced anodes can increase energy storage, translating to longer driving range per charge.

-

-

Fast Charging Capability

-

Reduced ion diffusion resistance enables 10–15 minutes ultra-fast charging, a major demand from EV consumers.

-

-

Improved Cycle Life

-

Graphene’s flexibility and conductivity reduce capacity fade, extending battery lifetime.

-

-

Safety Enhancements

-

Lower internal resistance reduces overheating risks during high-power charging.

-

5. Industrial and Commercial Progress

-

Tesla and Panasonic

-

Researching silicon-graphene composite anodes to increase EV range.

-

-

Chinese Battery Manufacturers (CATL, BYD)

-

Exploring graphene-enhanced lithium-ion cells for faster charging EV fleets.

-

-

European Initiatives

-

EU-funded projects are testing graphene composites for next-generation EV batteries, focusing on sustainability and recyclability.

-

-

Startups

-

Companies like Talga Resources and NanoXplore are scaling graphene production for automotive applications.

-

6. Challenges to Overcome

-

Cost of Graphene Production

-

High-quality graphene remains expensive, though CVD and liquid-phase exfoliation methods are improving scalability.

-

-

Manufacturing Integration

-

EV battery factories are optimized for graphite; switching to graphene requires equipment adaptation and process validation.

-

-

Standardization and Testing

-

Industry standards for graphene anodes are not yet fully established, delaying large-scale adoption.

-

7. Outlook for Export and Trade Opportunities

For exporters and suppliers in the EV supply chain, graphene-based anodes represent a growing market opportunity:

-

Battery Manufacturers seek next-gen materials to meet consumer demand for faster charging.

-

Automakers need longer-range, safer batteries to differentiate their EV models.

-

Installers and Distributors in emerging markets may benefit from lighter, high-performance packs where infrastructure is limited.

Companies with expertise in graphene sourcing, processing, or integration can gain a competitive edge in the EV industry.

Graphene-enhanced anodes could be a game-changer for EV batteries, addressing the limitations of graphite and enabling fast charging, higher capacity, and longer lifespan.

While challenges remain in cost and manufacturing integration, ongoing research and industrial scaling suggest that graphene-based EV batteries will become commercially viable in the near future. For businesses in the energy storage and export sectors, now is the time to position themselves in this evolving market.