Graphene in EMI Shielding: The Next Generation of Electronic Protection

⚡ Introduction: The Growing Challenge of Electromagnetic Interference (EMI)

In the modern world, we’re surrounded by electronic devices — smartphones, electric vehicles, 5G base stations, industrial sensors, and more. As the density of electronic components increases, so does the problem of electromagnetic interference (EMI). Uncontrolled EMI can cause:

-

Malfunctioning circuits

-

Reduced signal integrity

-

Data loss

-

Safety hazards in critical applications (e.g., aerospace, medical electronics)

Traditional EMI shielding solutions, like metal foils or meshes, are heavy, rigid, and prone to corrosion. That’s where graphene enters the scene — a next-generation material with excellent electrical conductivity, lightweight nature, and flexible form factors.

🧪 Section 1: What Is EMI and Why Shield Against It?

EMI is the disturbance generated by electromagnetic fields affecting the performance of nearby electronic devices. Sources include:

-

Wireless communication signals (4G, 5G, Wi-Fi)

-

Switching power supplies

-

Electric motors

-

High-frequency ICs

To mitigate EMI, materials must absorb or reflect these interfering waves, especially in the 0.1 MHz to 40 GHz range.

✅ A good EMI shielding material should be:

-

Electrically conductive

-

Lightweight

-

Corrosion-resistant

-

Processable into films, foams, coatings, or pastes

🧬 Section 2: Why Graphene is Ideal for EMI Shielding

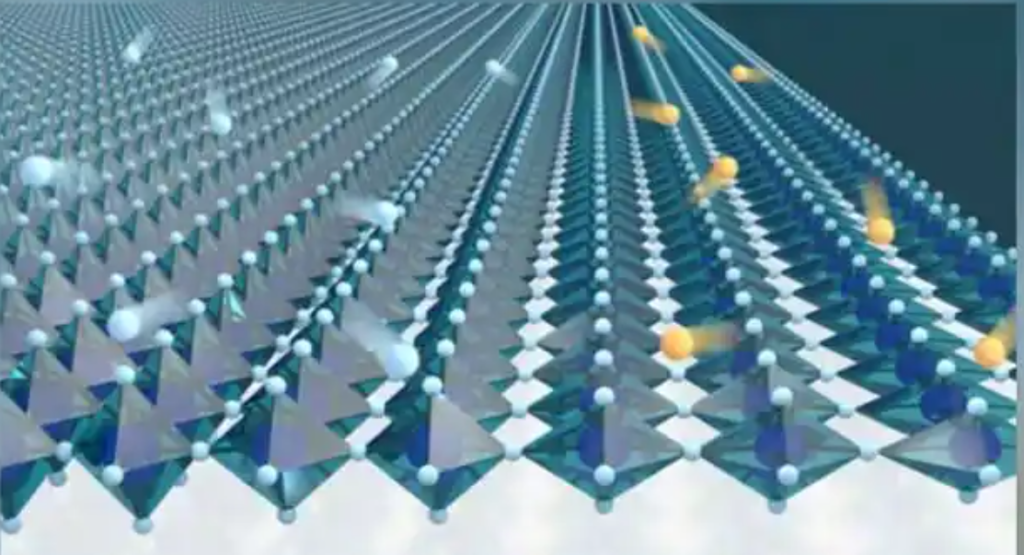

Graphene is a 2D carbon material with outstanding electromagnetic properties:

| Property | Value |

|---|---|

| Electrical conductivity | >10⁴ S/m |

| EMI shielding effectiveness (SE) | >60–90 dB (in composites) |

| Density | ~2.2 g/cm³ |

| Mechanical flexibility | High |

| Thermal stability | >500°C (in inert conditions) |

| Chemical resistance | Excellent |

💡 Compared to metal-based shielding (like Cu or Al), graphene offers:

-

Weight reduction by 50–80%

-

Flexible integration into wearable, curved, or miniaturized devices

-

Corrosion-free and longer-lasting performance

🔧 Section 3: Common Graphene-Based EMI Shielding Formats

-

Graphene-Coated Films

Thin polymer films coated with a layer of conductive graphene or rGO (reduced graphene oxide).

✅ Used in mobile devices, touchscreens, flexible electronics. -

Graphene Foams and Aerogels

Porous graphene structures that absorb electromagnetic waves via multiple internal reflections.

✅ Applied in aerospace and lightweight enclosures. -

Graphene-Polymer Composites

Injection-molded plastics (e.g., ABS, PP, PVDF) filled with graphene flakes or graphene oxide.

✅ Ideal for housings of automotive electronics and routers. -

Graphene Paints or Inks

Printable formulations for EMI shielding coatings on metal, plastic, or fabric substrates.

✅ Suitable for large-area shielding on drones, IoT devices, and machinery.

📈 Section 4: EMI Shielding Effectiveness (SE) Explained

EMI SE (Shielding Effectiveness) is typically measured in decibels (dB) — the higher, the better:

-

<20 dB: Minimal shielding

-

20–40 dB: Moderate (suitable for commercial electronics)

-

40–60 dB: High (industrial/automotive grade)

-

>60 dB: Critical protection (aerospace, military)

📌 Graphene-rich composites can achieve 60–90 dB SE in the 8–18 GHz band when properly structured (e.g., layered, oriented, conductive network).

🏭 Section 5: Application Scenarios for Graphene EMI Shielding

| Industry | Use Case | Graphene Form |

|---|---|---|

| Consumer Electronics | Shielding for smartphones, tablets, wearables | Coated film, composite shell |

| Automotive | EMI shielding for ADAS, BMS, EV ECUs | Graphene-polymer parts |

| Aerospace | Lightweight shielding for avionics, satellites | Aerogels, foams |

| Telecommunications | 5G base station enclosures | Paints, laminates |

| Medical Devices | Precision instrument casing, implantable electronics | Flexible graphene sheets |

✅ Graphene enables EMI protection without compromising weight, design, or thermal behavior — ideal for compact, high-frequency, or mobile applications.

🔬 Section 6: Case Study — Graphene-Rich EMI Shielding Film

At GrapheneRich NanoTech, our team developed a graphene oxide-based coating modified with conductive additives and dispersion agents (e.g., XFZ20) to achieve:

-

SE > 55 dB (8–12 GHz) in 10–20 µm films

-

Surface resistivity: ~10⁻²–10⁻¹ Ω/sq

-

Sprayable and printable on PET, PI, or metal foil

-

Flexible, crack-free under repeated bending

📦 Suitable for integration in flexible circuit boards, touch panels, and miniaturized modules.

🧠 Section 7: Graphene vs. Traditional EMI Materials

| Feature | Copper Foil | Carbon Black | Graphite | Graphene |

|---|---|---|---|---|

| SE (dB) | 70–90 | 10–20 | 30–45 | 60–90 |

| Density | High | Low | Medium | Low |

| Flexibility | Low | High | Medium | High |

| Corrosion | Prone | Stable | Stable | Excellent |

| Integration | Rigid | Limited | Molded | Coated, Printed, Molded |

📌 Graphene provides a unique combination of conductivity, flexibility, and processability unmatched by metals or traditional carbon.

🔮 Section 8: Future Outlook

As 5G, IoT, EVs, and wearable electronics grow in complexity and frequency, demand for high-performance, flexible EMI shielding materials will rise rapidly.

Graphene is poised to become:

-

A standard additive in EMI shielding polymers

-

A key coating material for lightweight enclosures

-

An enabler of EMI-shielded transparent electronics

At GrapheneRich, we believe in scalable solutions — developing formulations with reduced graphene oxide, composite fillers, and printable pastes tailored to industry needs.

🌐 Learn more about our EMI materials at: https://graphenerich.com/products