Graphene in Flexible Electronics: Powering the Next Generation of Wearable Technology

Introduction

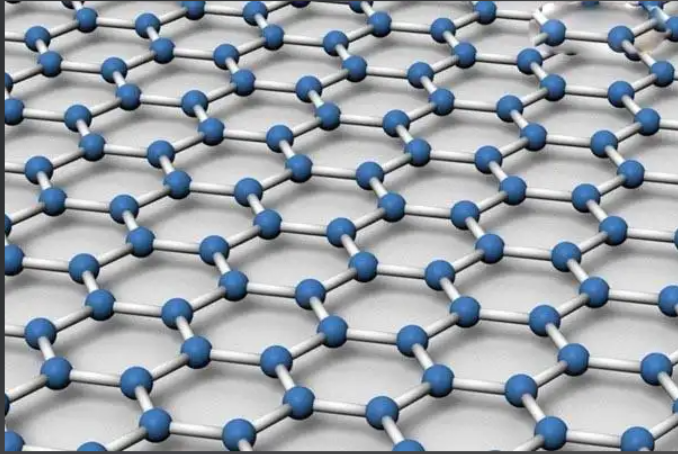

The age of wearable electronics and flexible devices is here — from smartwatches to electronic skin and bendable displays. These technologies require materials that are not just conductive, but also lightweight, stretchable, transparent, and biocompatible. Among all candidates, graphene stands out as a versatile platform for flexible electronics, enabling breakthroughs in smart healthcare, consumer devices, and IoT infrastructure.

1. Graphene’s Unique Suitability

-

Conductivity: Comparable to copper but at nanoscale thickness

-

Transparency: Over 97% optical transparency

-

Flexibility: Can bend, stretch, or conform without breaking

-

Thinness: Only one atom thick, ideal for wearable form factors

-

Chemical Sensitivity: Useful for biosensing and environmental detection

2. Key Applications of Graphene in Flexible Devices

a. Flexible Sensors

-

Pressure, strain, and humidity sensors for wearables

-

Medical patches for heart rate, respiration, and glucose monitoring

-

eSkin for robotics and prosthetics

b. Graphene-Based Displays

-

OLED and QLED substrates using transparent graphene electrodes

-

Foldable smartphones and tablets

-

Transparent touch panels for AR/VR headsets

c. Energy Storage on Flexible Substrates

-

Graphene supercapacitors and micro-batteries

-

Power supply layers in smart clothing

-

Integration with solar fabrics

d. Graphene Antennas and Interconnects

-

Used in wearable communication modules (Bluetooth, NFC)

-

Lower weight and higher resilience compared to metal antennas

3. Graphene E-Textiles

-

Graphene printed or woven into fabrics

-

Capable of sensing motion, temperature, or posture

-

Washable and durable

-

Examples: Smart jackets, yoga pants, sleep monitors

4. Research Highlights and Industrial Examples

-

University of Manchester: Developed graphene inks for flexible bio-sensors

-

Huawei: Filed patents on graphene-based phone cooling and wearable circuits

-

Vollebak (UK brand): Integrated graphene panels in sportswear for temperature regulation

-

MIT: Created graphene tattoo sensors for real-time biochemical monitoring

5. Fabrication Methods

-

Inkjet Printing: Graphene inks allow direct printing of circuits and sensors

-

CVD-Grown Films: High-quality graphene on polymer substrates

-

Laser Reduction of GO: Enables rapid, scalable patterning for circuit design

-

Roll-to-Roll Production: For low-cost mass manufacturing of graphene electronics

6. Challenges and Future Outlook

-

Power Integration: Flexible energy sources (graphene batteries, PV cells) still developing

-

Durability: Some graphene devices degrade under humidity or mechanical strain

-

Cost and Scalability: CVD graphene remains expensive, but ink and GO-based solutions are maturing

-

Regulatory Landscape: Standard testing methods for wearable graphene devices are evolving

Conclusion

Graphene’s blend of conductivity, flexibility, and biocompatibility makes it a linchpin material for wearable electronics and flexible devices. As health monitoring, smart fashion, and mobile computing evolve, graphene-enabled systems are expected to define how we wear, power, and interact with technology. For innovators in materials science and electronics, graphene represents both a commercial opportunity and a technological leap.