Graphene in Heat Dissipation Films: Powering 5G and Foldable Smartphones

Introduction

With the explosion of 5G networks, foldable phones, and high-performance mobile devices, managing heat has become one of the most critical challenges in electronics design. Graphene, the one-atom-thick carbon material renowned for its ultra-high thermal conductivity (~5300 W/m·K), has become a material of choice in the new generation of thermal interface solutions. In China, several companies have successfully mass-produced graphene-based heat dissipation films, making them a cornerstone in the thermal management of smartphones, tablets, laptops, and wearable devices.

Why Heat Management Matters in 5G and Foldable Devices

-

5G chips generate more heat than 4G due to higher frequencies and faster processing.

-

Foldable devices have limited space for conventional heat sinks or fans.

-

Thermal throttling directly impacts user experience and device performance.

-

Battery safety and longevity depend heavily on stable operating temperatures.

This environment sets the stage for advanced materials like graphene to step in.

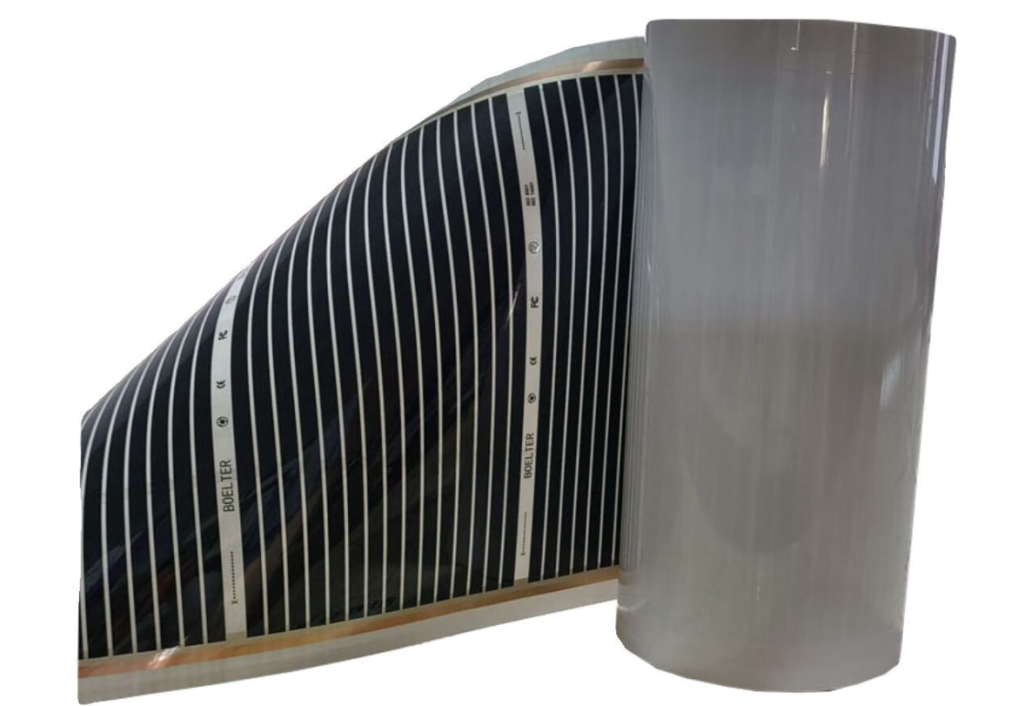

What Are Graphene Heat Dissipation Films?

Graphene thermal films are typically composed of layered graphene sheets or reduced graphene oxide (rGO) laminated into thin flexible sheets with thicknesses ranging from 10 to 100 microns. Key types include:

-

Graphene-PET/PI hybrid films

-

High-purity graphite/graphene laminates

-

Graphene-enhanced thermal interface layers (TIMs)

These films are usually sandwiched between heating sources (chips or batteries) and device casings or heat spreaders.

Advantages Over Traditional Materials

| Property | Graphene Film | Conventional Graphite | Metal (Al/Cu) |

|---|---|---|---|

| Thermal Conductivity (W/m·K) | 1000–1800 | 400–600 | 200–400 |

| Thickness | ~10–50 μm | 50–100 μm | >100 μm |

| Flexibility | Excellent | Moderate | Poor |

| Weight | Ultra-light | Moderate | Heavy |

China’s Progress in Mass Production

Several Chinese manufacturers have scaled up graphene film production to millions of square meters annually, targeting smartphone OEMs and battery companies.

Typical Features:

-

Roll-to-roll processing of graphene sheets

-

Customizable size and flexibility

-

Thermal conductivity over 1500 W/m·K

Leading Companies (anonymized or public domain):

-

Manufacturers in Shenzhen, Ningbo, Changzhou, and Dongguan

-

Supply chain connections with Xiaomi, Oppo, Vivo, and Huawei

-

Joint R&D with universities and public research institutes

Real-World Applications

-

Smartphones: Used as heat spreaders behind screens or around CPU areas

-

Foldable Phones: Integrated into flexible hinges and OLED backing layers

-

Tablets and Laptops: As part of the battery pack and touch panel structure

-

Smartwatches & Bands: Ultra-thin films for compact enclosures

Case Highlight:

A leading domestic graphene producer developed a 20 μm graphene laminate with thermal conductivity exceeding 1700 W/m·K. It is now deployed in over 30 million mobile devices and contributes to an average device surface temperature drop of 3–5°C under high-load scenarios.

Challenges and Future Trends

-

Cost reduction: R2R processing is helping, but still more expensive than graphite

-

Adhesion and integration: Compatibility with different device layers

-

Composite innovation: Hybrid graphene + PCM (phase change materials) under development

Future trends include:

-

Integration with AI chips and VR/AR devices

-

Graphene-based encapsulation with EMI shielding

-

Multifunctional films: thermal + structural + conductive

Conclusion

China’s rapid advancement in graphene heat dissipation films represents a leap from lab to fab. As thermal management becomes a key design bottleneck in next-gen electronics, domestically produced graphene films are not only solving real problems—they are showcasing how advanced materials can scale into real-world products.

Graphene’s ultra-thin, lightweight, and high-performance nature makes it ideal for the next wave of compact, high-power devices. And in China, that wave is already here.